Apparatus for drying printed material provided with printing ink

A technology of printing ink and printing materials, applied in the direction of drying gas arrangement, general parts of printing machinery, printing, etc., to achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

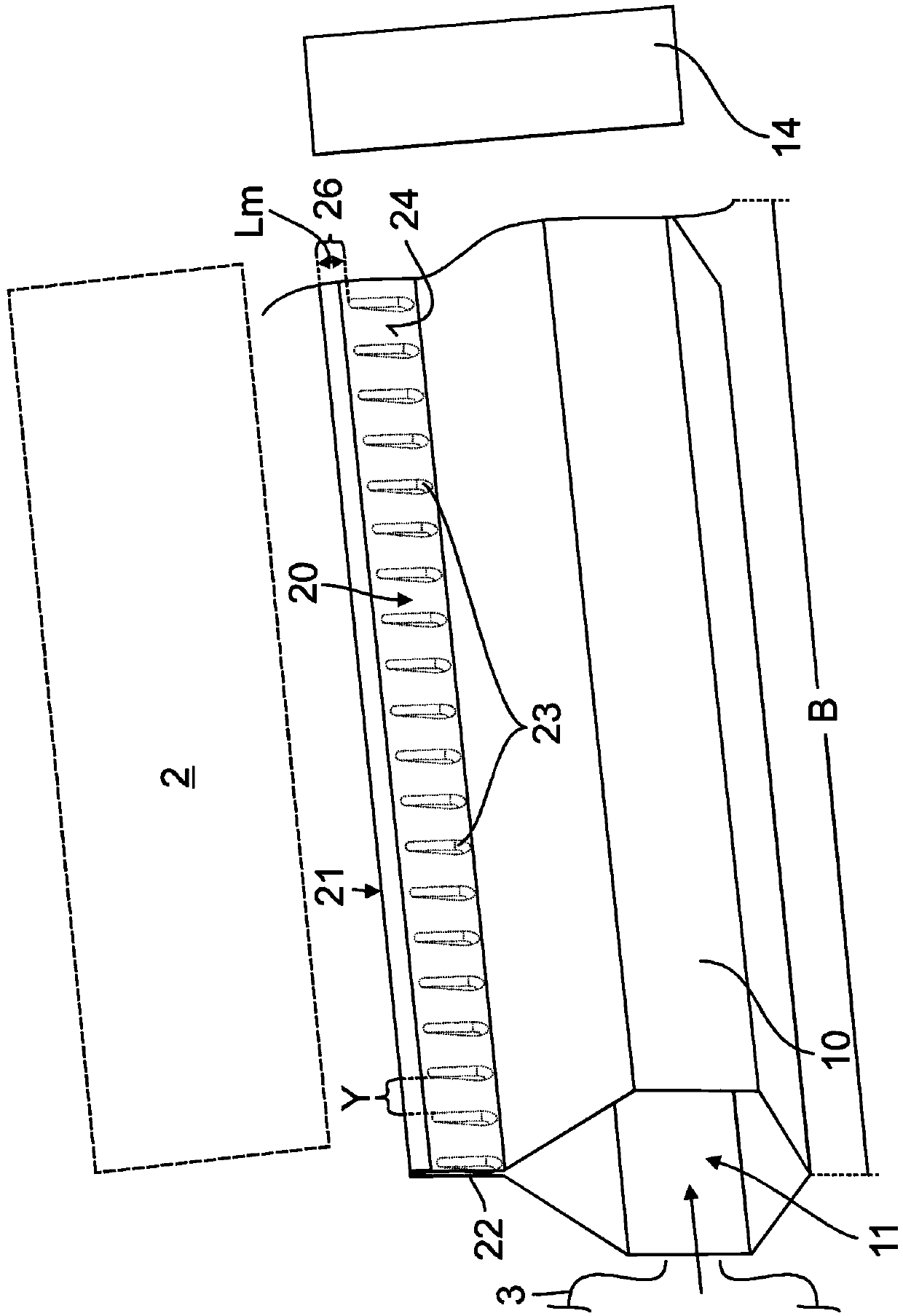

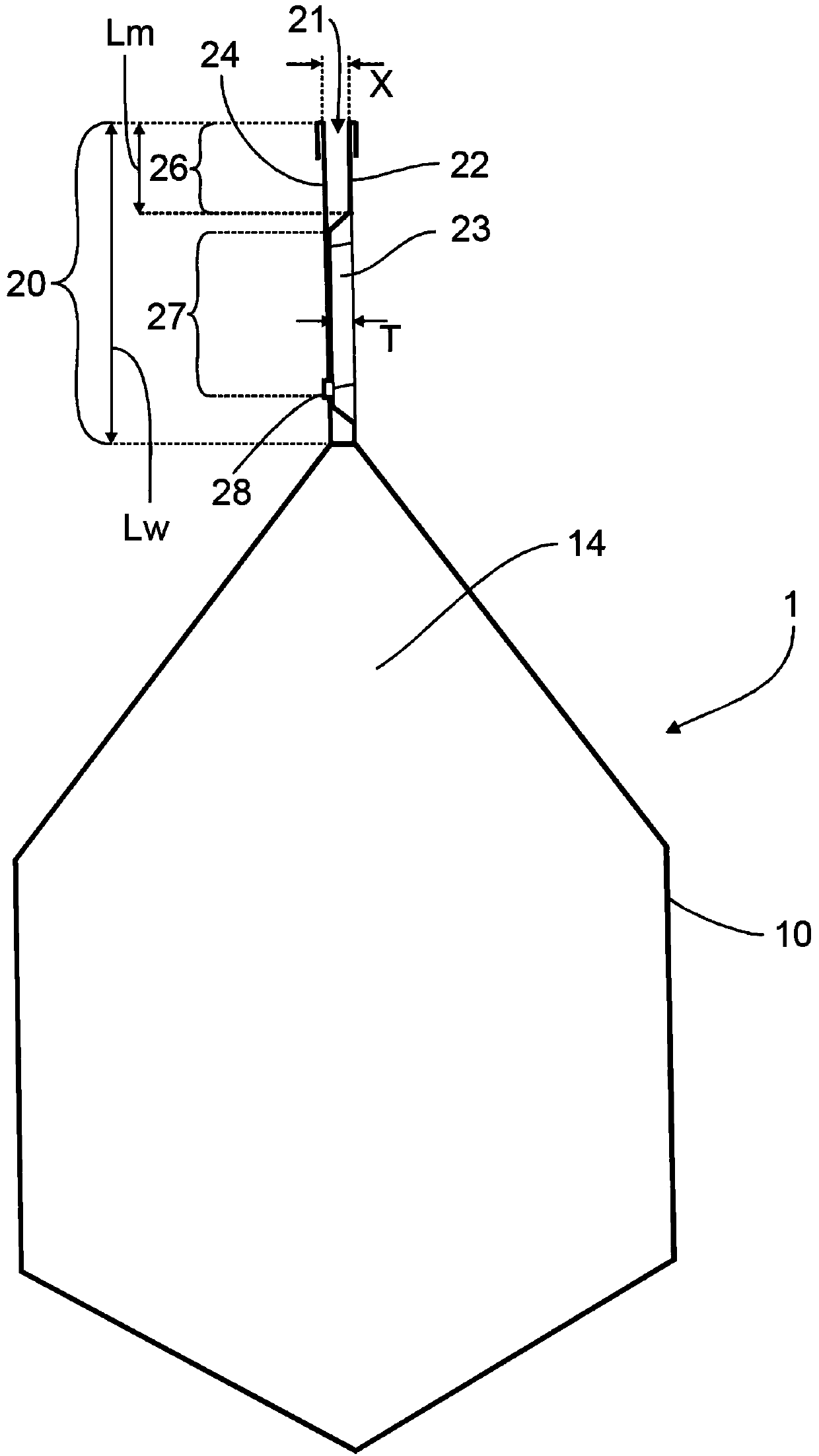

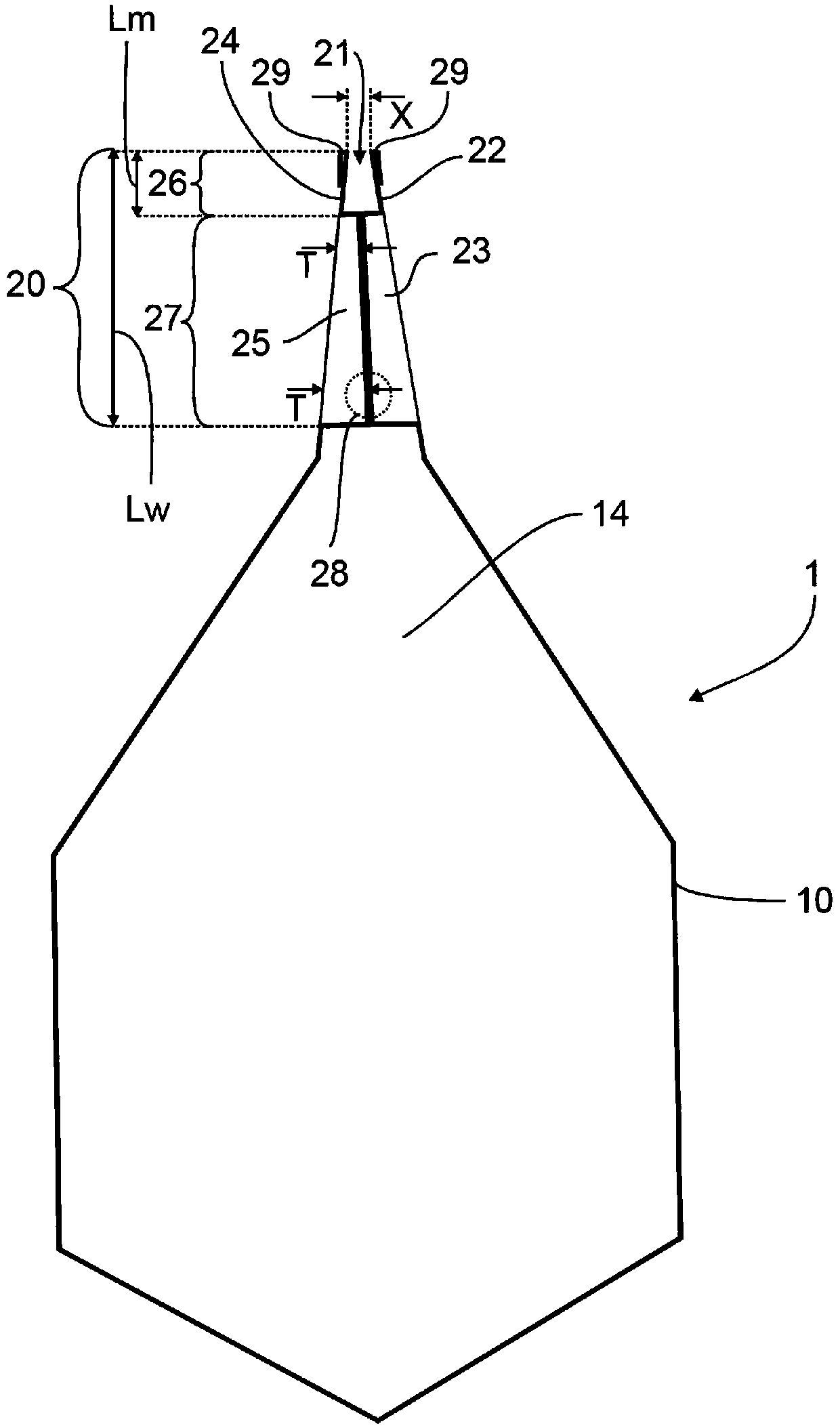

[0060] figure 1 A device 1 for drying printed material provided with printing ink in a printing press 2 is shown. The printing press 2 is shown only schematically, the printed material with printing ink not being explicitly shown in the exemplary embodiment shown. The printing press 2 can be, for example, a gravure printing press or a flexographic printing press, wherein the device 1 according to the invention, which can also be referred to as a blower unit, causes a gaseous medium to flow in the direction of the printed material. Advantageously, heated air is used as gaseous medium in order to increase the efficiency of drying. For example, air or another suitable gas can also be used as medium. The device 1 according to the invention is preferably connected to a piping system 3 which conducts a gaseous medium into the hollow body 10 of the device 1 according to the invention. The device 1 serves primarily to distribute the supplied medium uniformly over the entire width o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com