Heat management system of hybrid electric vehicle

A thermal management system, hybrid technology, applied in electric vehicles, vehicle components, vehicle energy storage, etc., can solve the problems of increased system power consumption, unutilized system waste heat, energy waste, etc., to reduce system power consumption, improve Energy efficiency, the effect of reducing the number of starts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

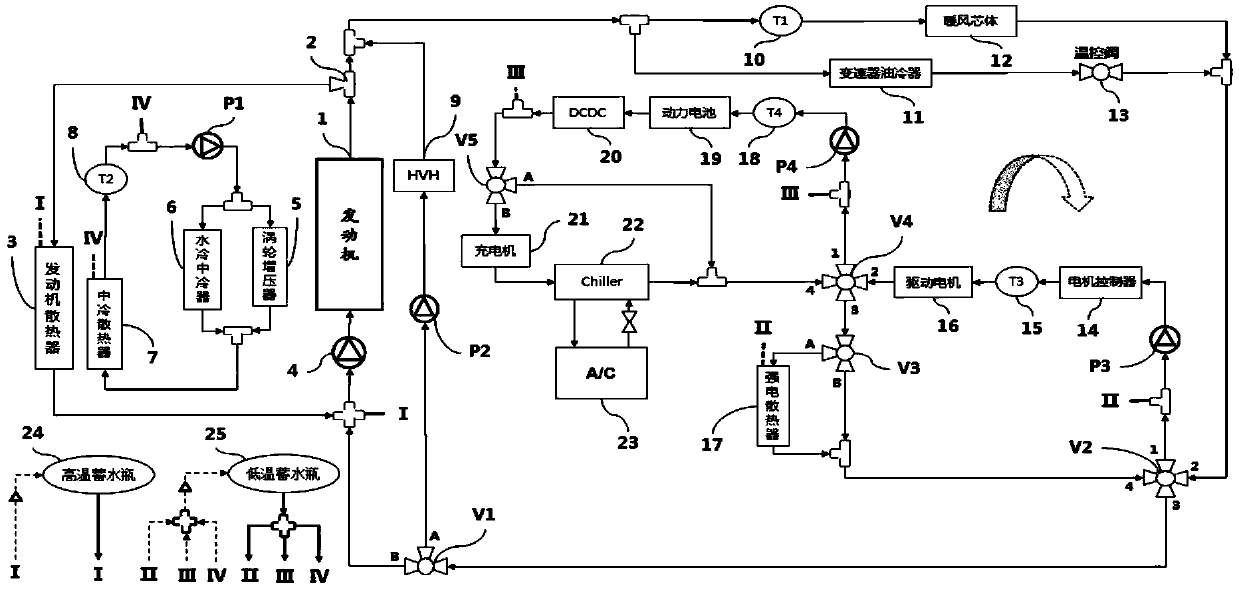

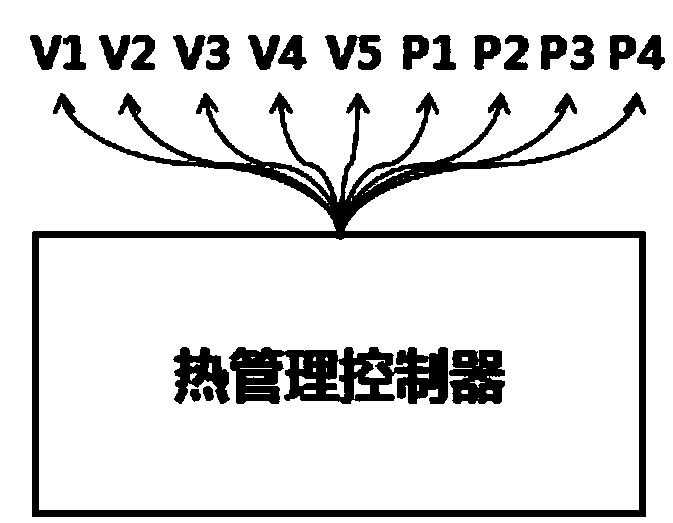

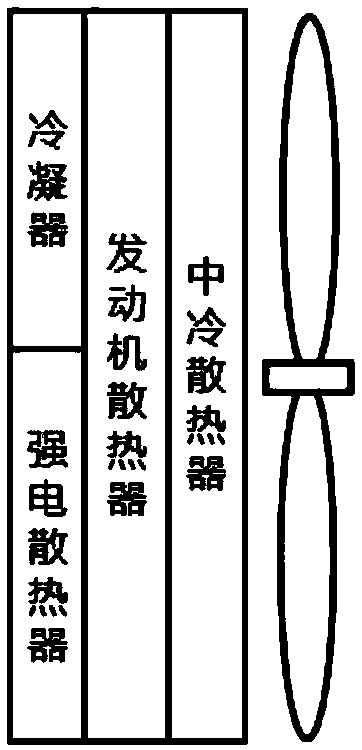

[0040] Embodiment 1: This embodiment is a thermal management system for a plug-in hybrid electric vehicle, including an engine cooling system, an intercooler cooling system, a heating system, a strong electric system cooling system, a battery cooling system, and an air-conditioning system. Such as figure 1 As shown, a four-way valve V4 is set between the high-power cooling system and the battery cooling system to communicate with the two circuits. The four-way valve V4 is set between the drive motor downstream of the high-power cooling system and the Upstream of the electronic water pump of the battery cooling system, according to the needs of battery cooling and heating, by switching the mode of the four-way valve V4, the power system cooling system and the battery cooling system are connected or disconnected to maximize the function of the components , to reduce system power consumption. A four-way valve V2 is set between the cooling system of the strong electric system and...

Embodiment 2

[0074] Embodiment 2: as Figure 4 As shown, the function of the three-way valve V5 in Embodiment 1 is to prevent the antifreeze from passing through it when the charger 21 and the battery cooler 22 are not working, so as to reduce the water resistance of the circuit, but it can also meet the water flow rate of the battery cooling circuit. On the basis of requirements, the three-way valve V5 is canceled to reduce the cost of components and the complexity of the system.

Embodiment 3

[0075] Embodiment 3: as Figure 5 As shown, for hybrid vehicles without external charging mode, there is no charger. Therefore, after canceling the charger 21 on the basis of implementation case 2, the system can be adapted to general hybrid vehicles, and its working mode can be referred to Implementation Case 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com