Repairing method for acid goaf water

A repair method, acidic technology, applied in chemical instruments and methods, water/sewage treatment, mining wastewater treatment, etc., can solve problems such as large impact, failure to perform normally, weak acidity of old kiln water, etc.

Inactive Publication Date: 2019-04-05

TAIYUAN UNIV OF TECH

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] 2. Oxygen content: The oxidation process of sulfide minerals is greatly affected by the oxygen concentration. In a humid oxidizing environment, the oxidation rate is proportional to the oxygen concentration. Without sufficient oxygen content, the process will not proceed normally.

[0006] 3. Conditions for groundwater replenishment and drainage: in the old empty area with sufficient oxygen content and accumulated water, the oxidation rate of sulfide is faster, and the generated sulfate is easy to be enriched in the old empty area, with a higher concentration and stronger However, when there is a stable supply water source, and the conditions of groundwater replenishment and drainage are completely renewed and quickly updated, sulfate will continue to be washed and discharged with groundwater, and its concentration will also decrease accordingly. Therefore, the old kiln water formed less acidic

[0007] 4. Time factor: the length of water accumulation in the old empty area affects the reaction degree of sulfide

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0039] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] 1. Experimental study on the adsorption of loess to remediate acidic old kiln water

[0041] 1.1 Experimental materials

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Login to View More

Abstract

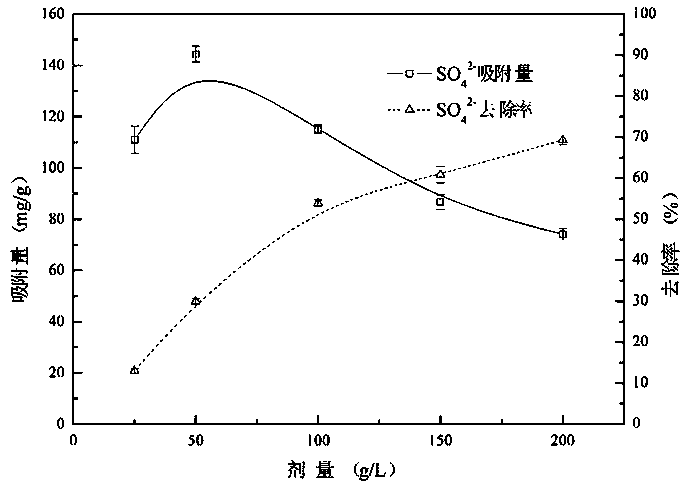

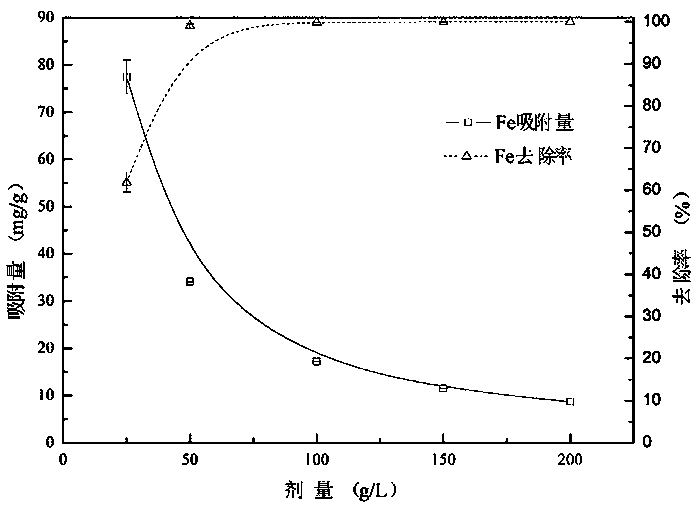

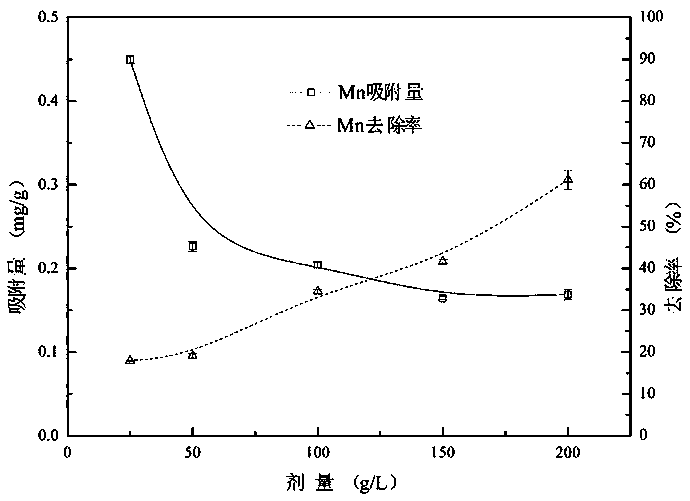

The invention discloses a repairing method for acid goaf water. The repairing method includes 1, applying an adsorption kinetics method, to be more specific, placing air-dried loess in an oven at thetemperature of 105 DEG C for 24 hours until a constant weight is achieved, sieving the loess by a 200-mesh sieve, and storing the sieved loess for standby use; adding 25-200g of the loess per liter ofthe acid goaf water, and oscillating the acid goaf water at the temperature of 25-45 DEG C and at the speed of 200r / min for 10-60 minutes to treat the acid goaf water; 2, selecting a soil column, laying 2cm-thick quartz sand at the bottom of the soil column, filling the soil column with an air-dried soil sample section by section before compacting, laying 2cm-thick quartz sand on the soil sampleafter filling, and leaching the acid goaf water. The repairing method has the advantages that the adsorption characteristics of the loess on typical pollutants in the acid goaf water are studied, andthe repairing function of a PRB system synergistic material on the goaf water is defined.

Description

technical field [0001] The invention relates to the technical field of water resource protection and treatment, in particular to a repair method for acidic old kiln water. Background technique [0002] my country is rich in coal resources, mainly underground mining. The goaf is formed after the coal seam is mined, and the goaf that has stopped mining and the recession period of surface movement and deformation has ended will become the old goaf. The old empty area becomes a space where groundwater gathers. The sulfide minerals in the coal seam undergo a series of physical and chemical reactions in the oxidizing environment and under the action of microorganisms. The reacted substances dissolve in water and gather in the old empty area. Water (Acid Mine Drainage, referred to as AMD) characteristics. [0003] When the mined-out area formed after coal seam mining meets the conditions for water accumulation, the water quality in the old goaf area will become acidic with high s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F1/28C02F103/10

CPCC02F1/281C02F2103/10

Inventor 郑强时红常爱泽张永波吴艾静

Owner TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com