Mould for producing and processing glass art craft

A technology of handicrafts and molds, which is applied in the field of molds for glass handicraft production and processing, which can solve the problems of glass handicrafts being difficult to form, mold temperature control, and health hazards, and achieve the effects of protecting human health, better forming effect, and reducing absorption

Inactive Publication Date: 2019-04-05

阜宁长鑫工艺品有限公司

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the temperature of the mold cannot be controlled during the production and processing of glass handicrafts, which often leads to difficult molding of glass handicrafts and poor molding effect. At the same time, smoke is easy to be generated during glass production and processing. health hazard

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

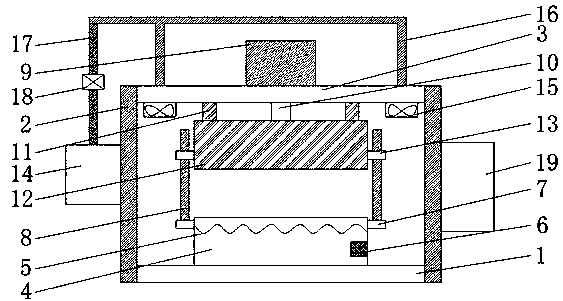

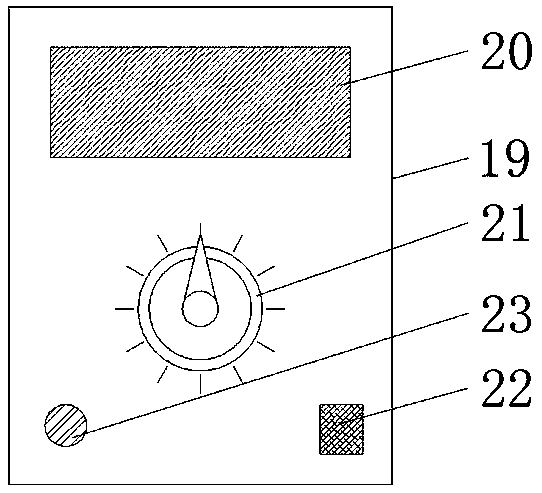

The invention discloses a mould for producing and processing a glass art craft. The mould comprises a bottom plate. Two sides of the top of the bottom plate are fixedly connected with side plates. Thetops of the two side plates are fixedly connected with a same top plate. A center of the top of the bottom plate is provided with a lower mould. The lower mould is internally provided with a heatingwire and a temperature sensor. Outer walls at two sides of the lower mould are fixedly connected with fixing blocks. The tops of the fixing blocks are fixedly connected with a guide rod. A center of the top of a top plate is provided with a cylinder. The output end of the cylinder is provided with an output shaft. Two sides of the bottom of the top plate are provided with telescopic rods. The bottom ends of the two telescopic rods are fixedly connected with a same upper mould. Outer walls at two sides of the upper mould are provided with guide blocks. The outer wall of the side plate at one side is provided with a purification water tank. The mould is capable of controlling a temperature of the mould, enabling the glass art craft to be more easily formed, wherein the forming effect is better, collecting and purifying smoke, reducing absorption to the smoke by a human body, and protecting human health.

Description

technical field [0001] The invention relates to the technical field of glass processing, in particular to a mold for production and processing of glass handicrafts. Background technique [0002] Glass handicrafts, also known as glass handicrafts, are products with artistic value made by manually processing glass raw materials or glass semi-finished products. It fully embodies the creativity and artistry of human beings. It comes from life, but it is higher than life. Glass crafts are generally divided into three categories: molten glass crafts, lampwork glass crafts, and glazed crafts, and are often used as decorative materials or high-end business gifts. At present, the temperature of the mold cannot be controlled during the production and processing of glass handicrafts, which often leads to difficult molding of glass handicrafts and poor molding effect. At the same time, smoke is easy to be generated during glass production and processing. Health hazard. Contents of th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03B23/00C03B11/12B01D47/02

CPCC03B23/00B01D47/021C03B11/12

Inventor 刘左成

Owner 阜宁长鑫工艺品有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com