Method for increasing extraction borehole gas extraction concentration through auxiliary boreholes

A drainage drilling and gas drainage technology, applied in the direction of gas discharge, earthwork drilling, mining equipment, etc., can solve the problems of gas drainage concentration decrease, gas drainage concentration decrease, gas leakage increase, etc., to achieve reduction The generation of borehole fractures, the effect of increasing the concentration of gas drainage and reducing greenhouse gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

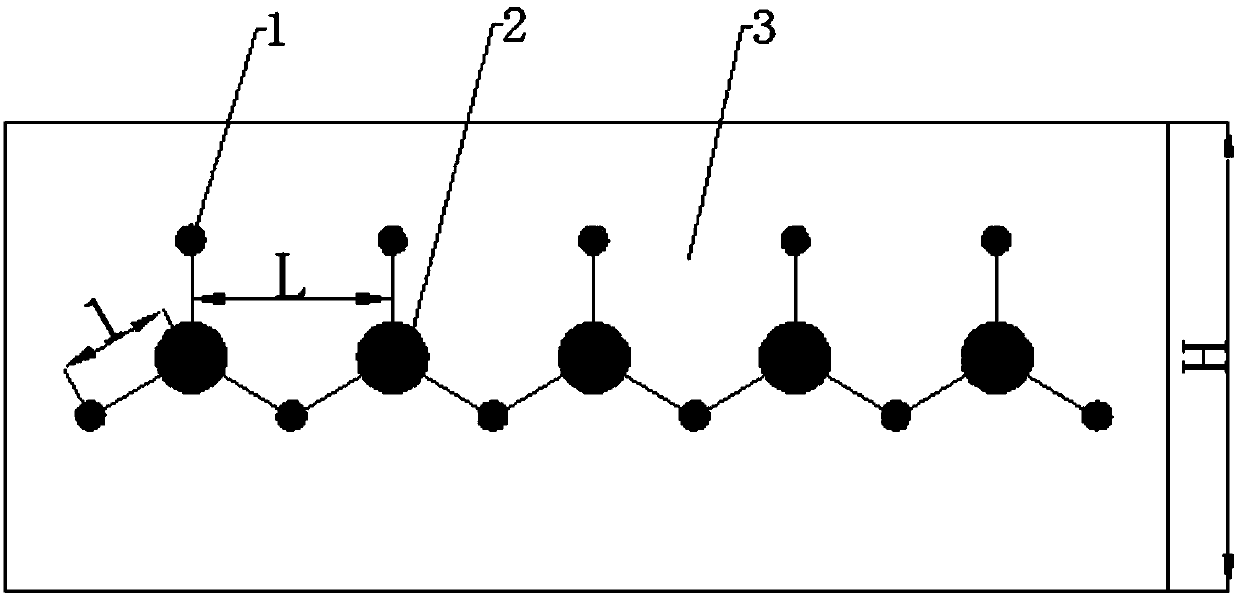

[0023] Such as figure 1 As shown, a method for increasing the concentration of gas drainage in drainage boreholes through auxiliary drilling comprises the following steps:

[0024] In the first step, a drilling rig using a 30mm drill pipe is used to construct multiple drainage boreholes side by side on the coal seam of the roadway, and a drilling rig using a 80mm drill pipe is used to ream the hole on the basis of the 30mm drilling; Distance L=0.43H±l 0 , H is the height of the coal seam, the error l 0 Must not exceed 0.0625H;

[0025] The second step is to use the gas drainage pipe bound with cotton cloth at both ends to seal the borehole, and use the gas drainage pipe to perform preliminary drainage of the gas in the borehole; when the gas drainage concentration is lower than 50%, the two ends Install polyurethane sealing bags to furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com