Efficient, energy-saving and environment-friendly high-temperature calcination device for electrode paste raw materials

A high-efficiency energy-saving, high-temperature calcination technology, applied in lighting and heating equipment, electric charge control, furnace type, etc., can solve the problems of slow feeding at the edge of the furnace, waste of energy, bias current, etc., to ensure process stability and increase heat transfer distance , the effect of uniform calcined quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

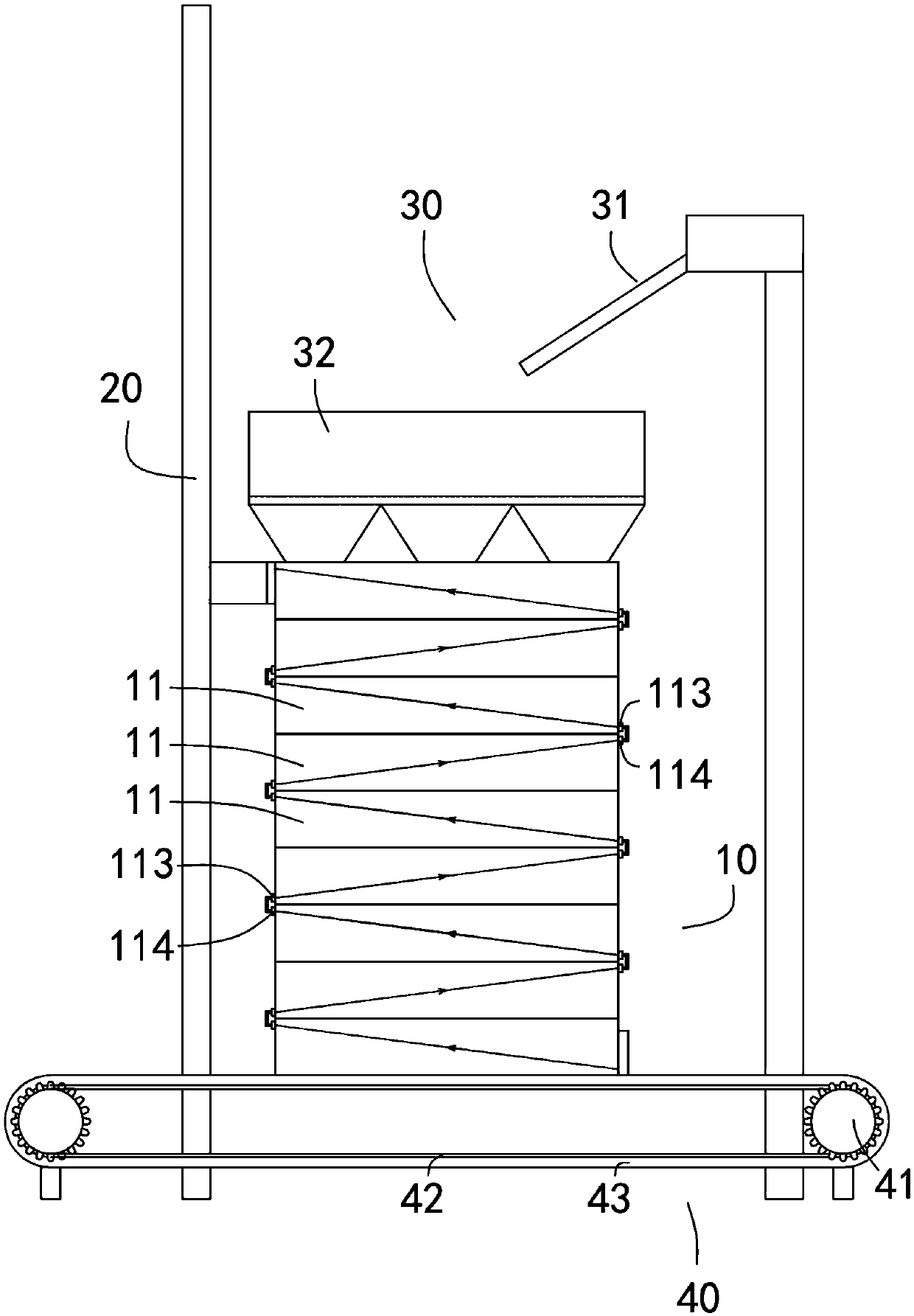

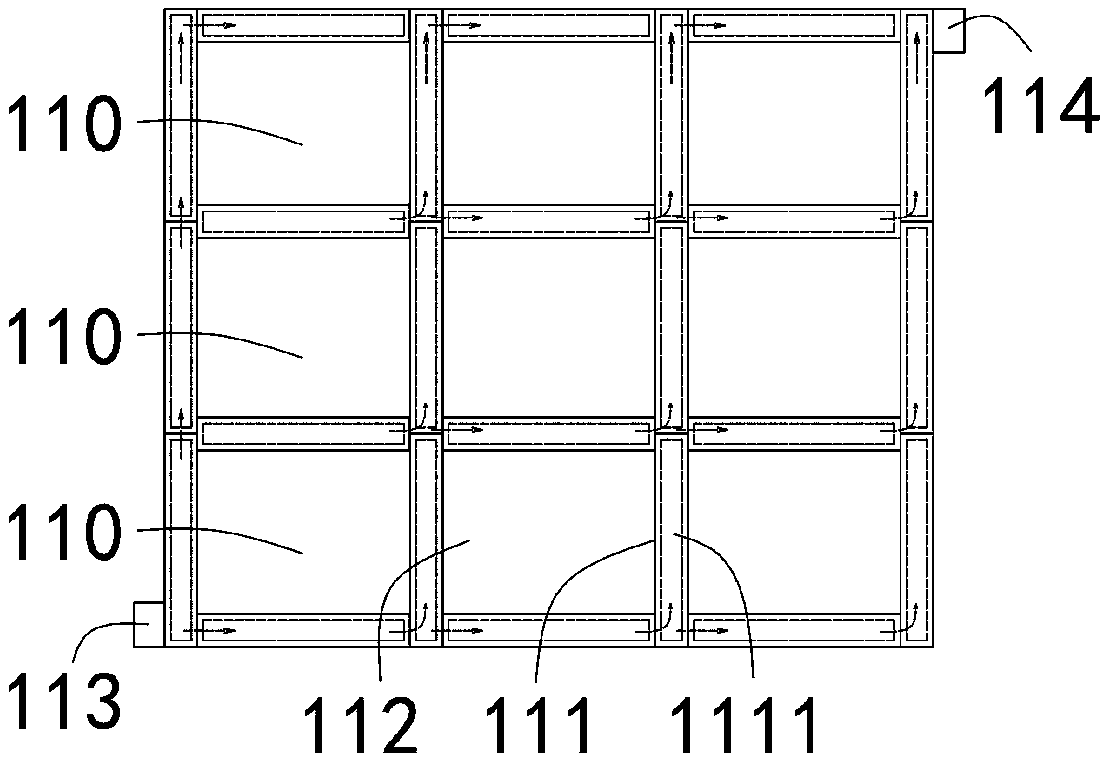

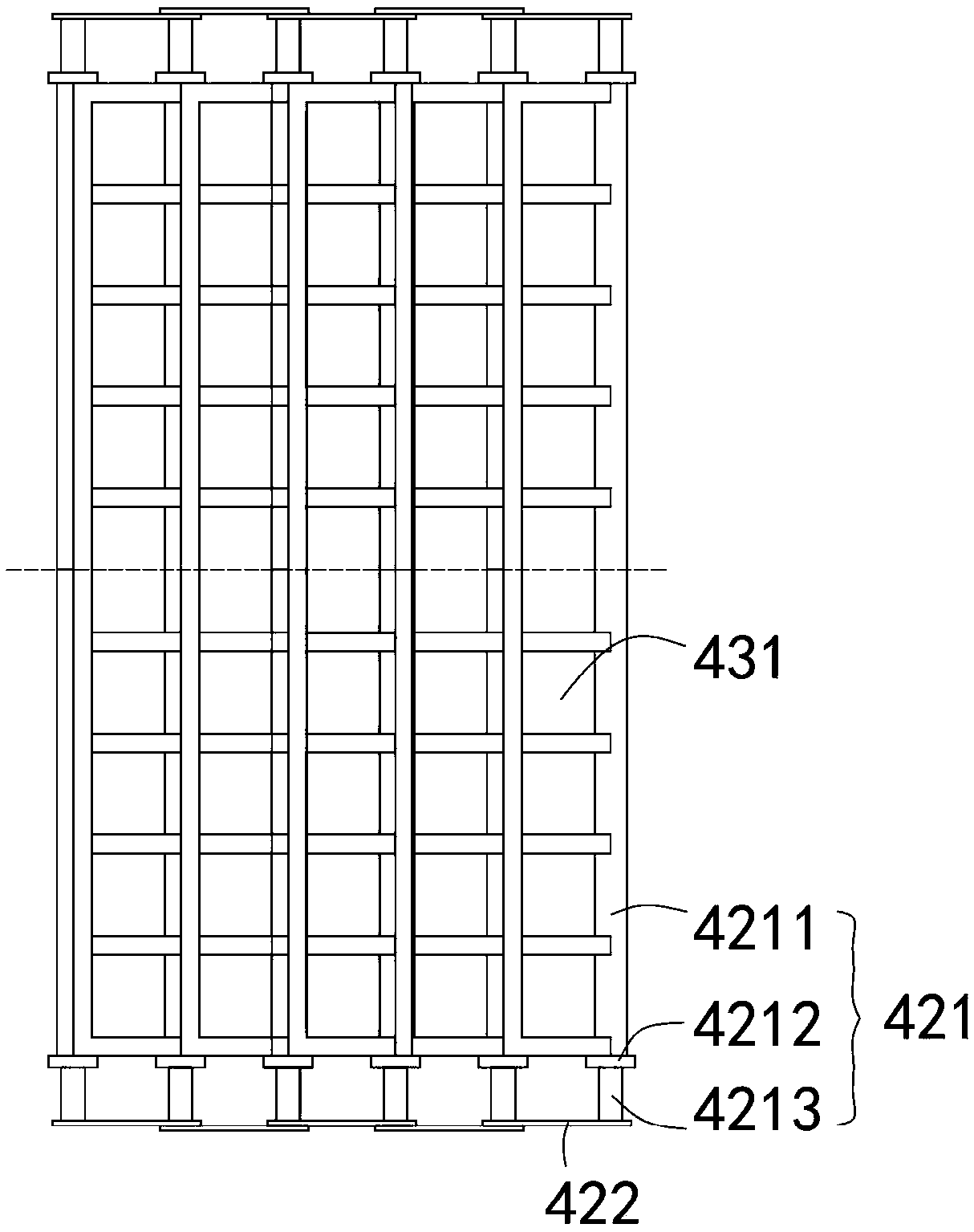

[0017] see Figure 1 to Figure 4 , the embodiment of the present invention provides a high-efficiency, energy-saving and environmentally friendly electrode paste raw material high-temperature calcination equipment, including a furnace 10, a chimney 20, a feeding mechanism 30, a discharge mechanism 40, and a controller. The furnace 10 includes at least nine unit furnaces with the same structure Body 11, each unit furnace body 11 includes at least nine unit chambers 110, each unit chamber 110 has a material channel 112, the material cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com