Electron microscope sample multifunctional ultrathin trimming device

An electron microscope sample, multi-functional technology, applied in the measurement device, the preparation and sampling of test samples, etc., can solve the problems of long time, unfavorable batch operation, wear of the UC7 instrument base, etc., and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

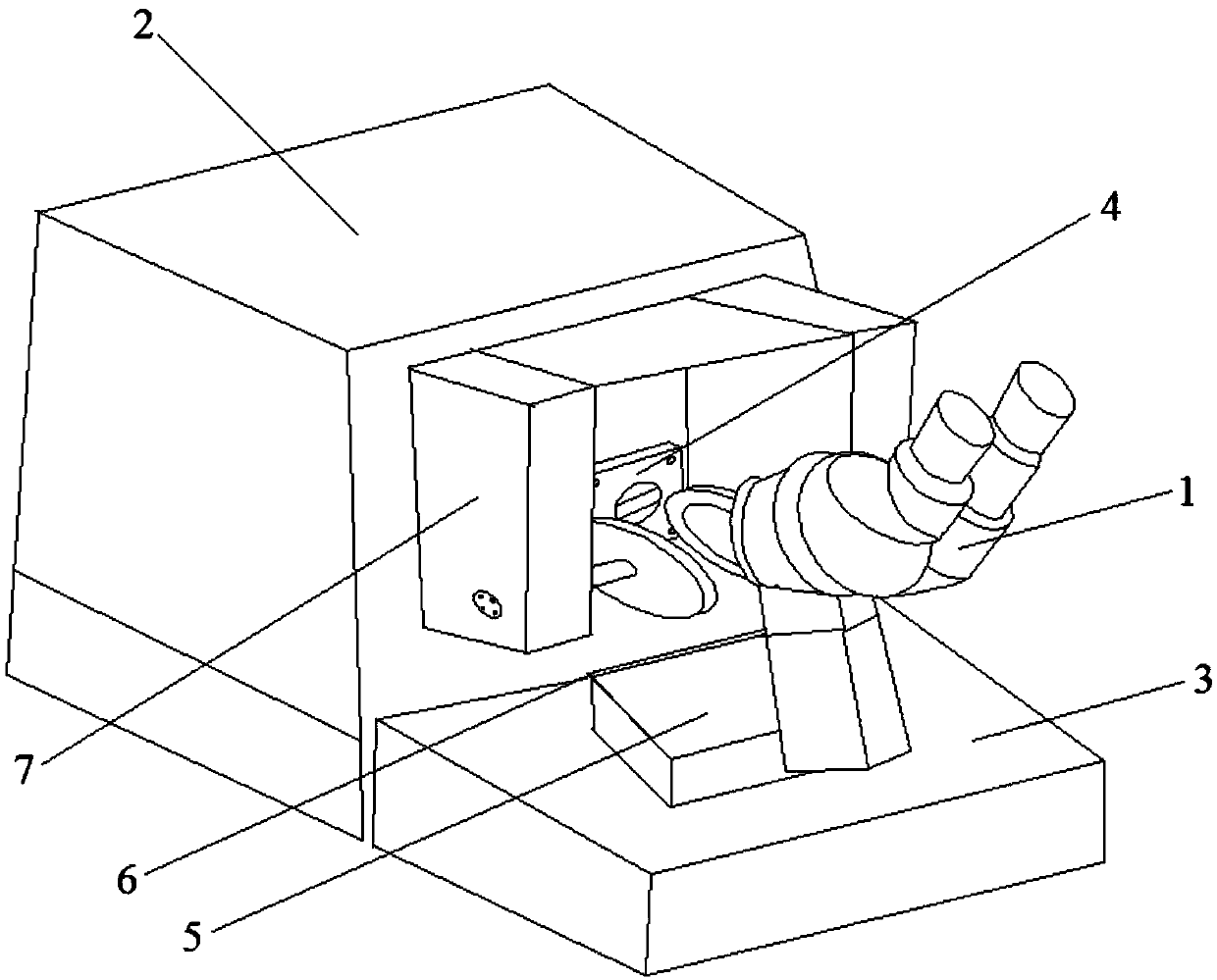

[0026] Such as figure 1 As shown, a multifunctional ultra-thin trimming device for electron microscope samples includes an electron microscope 1 and a microtome 2. The electron microscope 1 is an ordinary optical microscope, which is used to observe the rough trimming, finishing or slicing of samples, so as to zoom in or out. Adjust operation. The microtome 2 includes a base 3 and a sample clamping head 4 and a blade clamping head 5 arranged on the base 3. A blade 6 is installed on the blade clamping head 5, and the blade 6 is made of glass with higher hardness. knives, milling cutters, diamond cutters, etc., the base 3 is also provided with a rough repair mechanism 7.

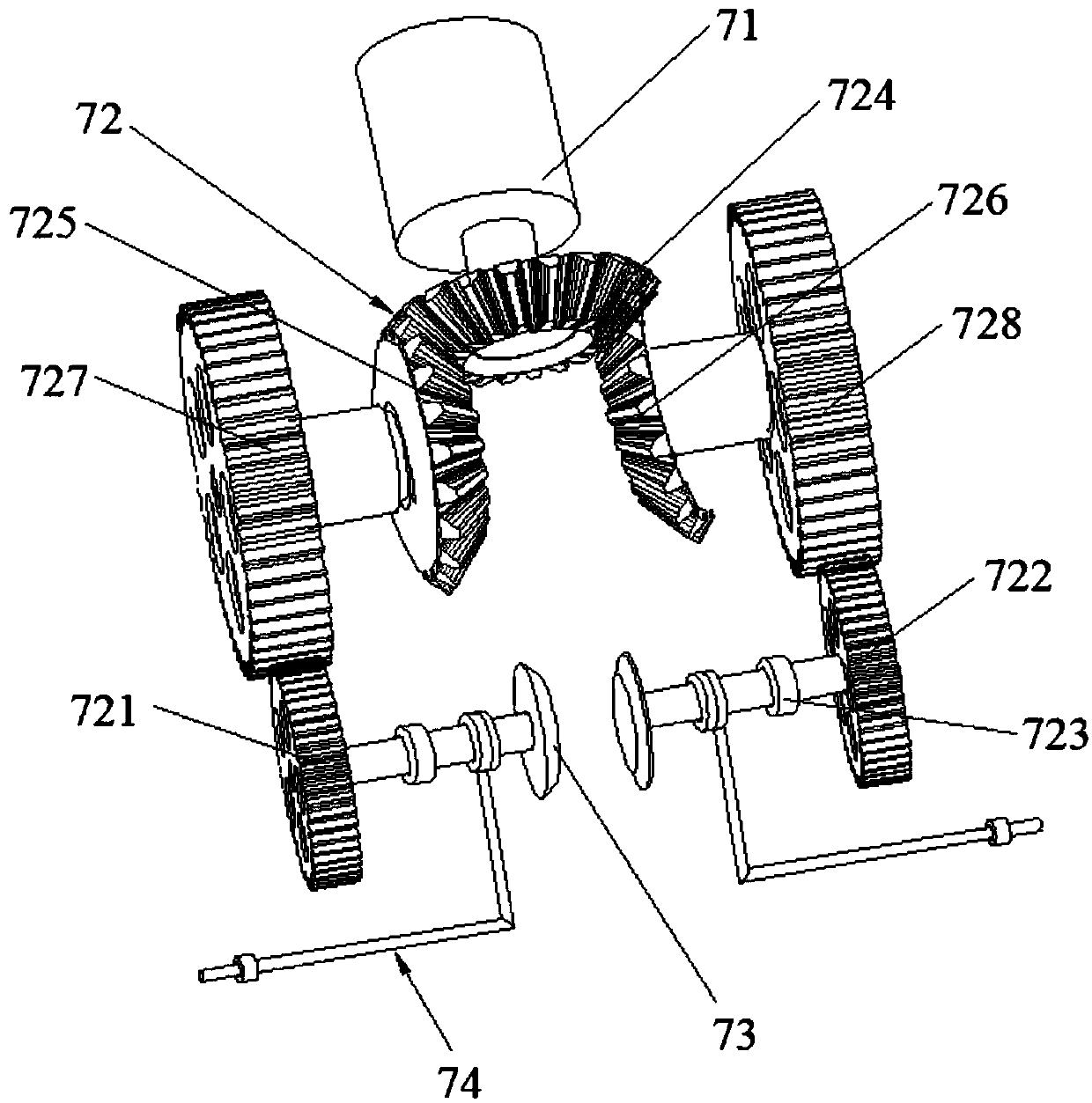

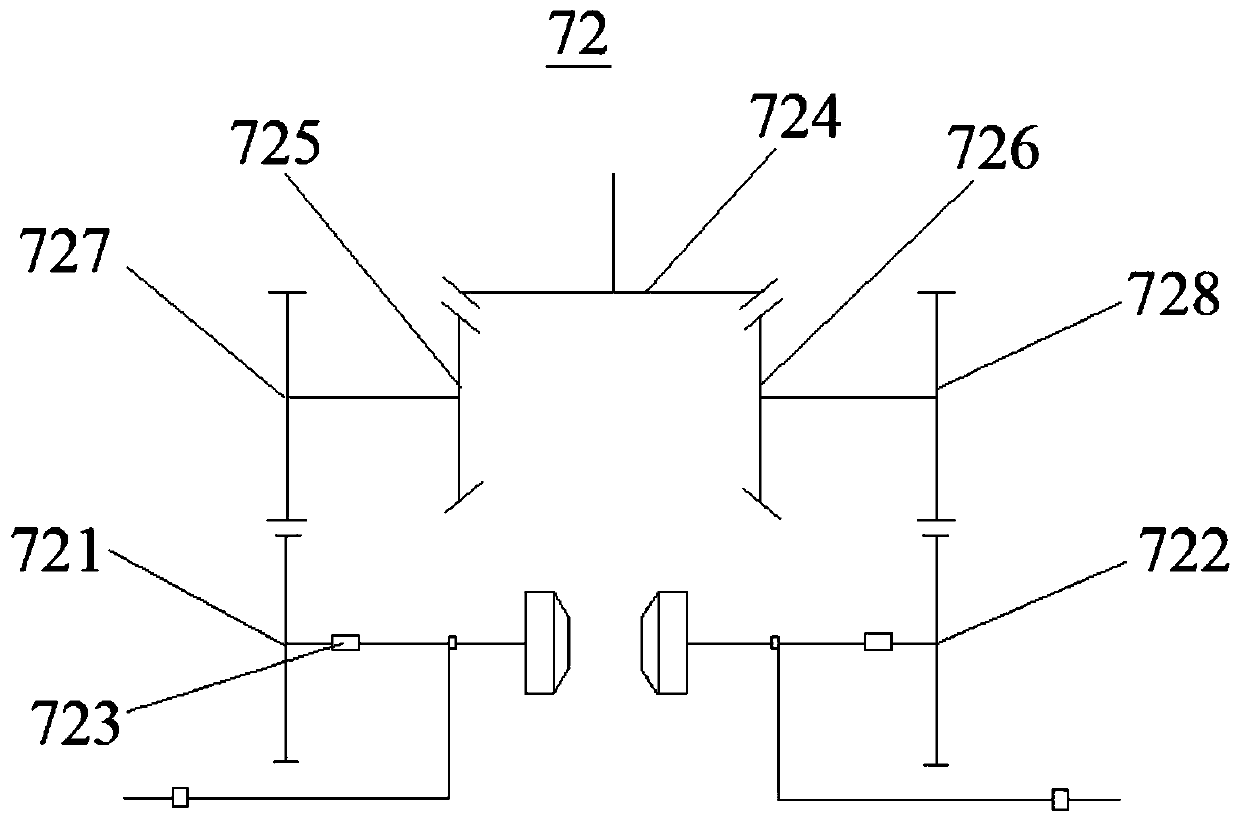

[0027] Such as figure 2 and image 3 As shown, the rough repair mechanism 7 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com