Buckle-type miniature rechargeable lithium battery structure member

A technology for rechargeable lithium batteries and structural components, which is applied to battery pack parts, structural parts, batteries, etc., can solve the problems of low battery assembly yield and low battery capacity, and achieve easy large-scale manufacturing and automatic assembly. The effect of high ratio and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The embodiments of the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings. The following embodiments are only used to explain the technical solutions of the present invention more clearly, and therefore are only used as examples, and cannot be used to limit the protection scope of the present invention.

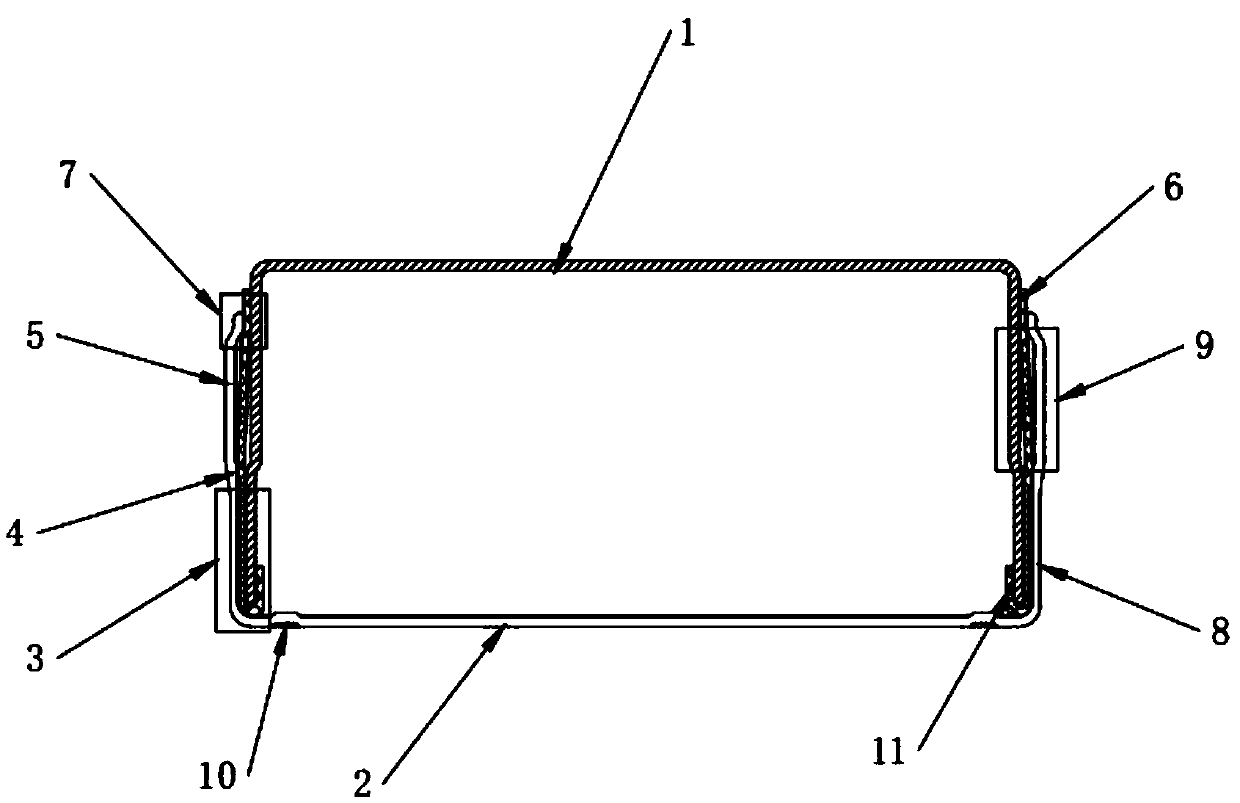

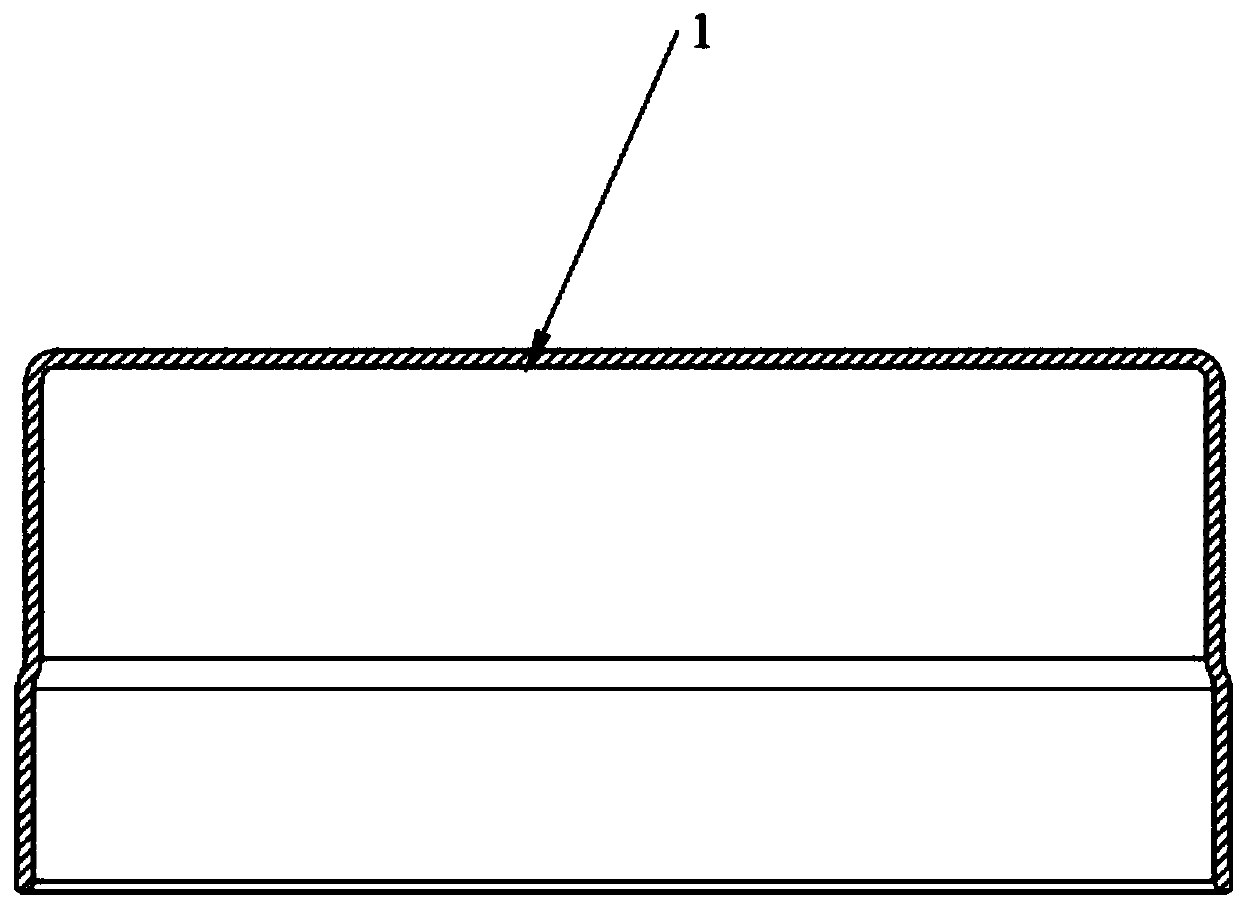

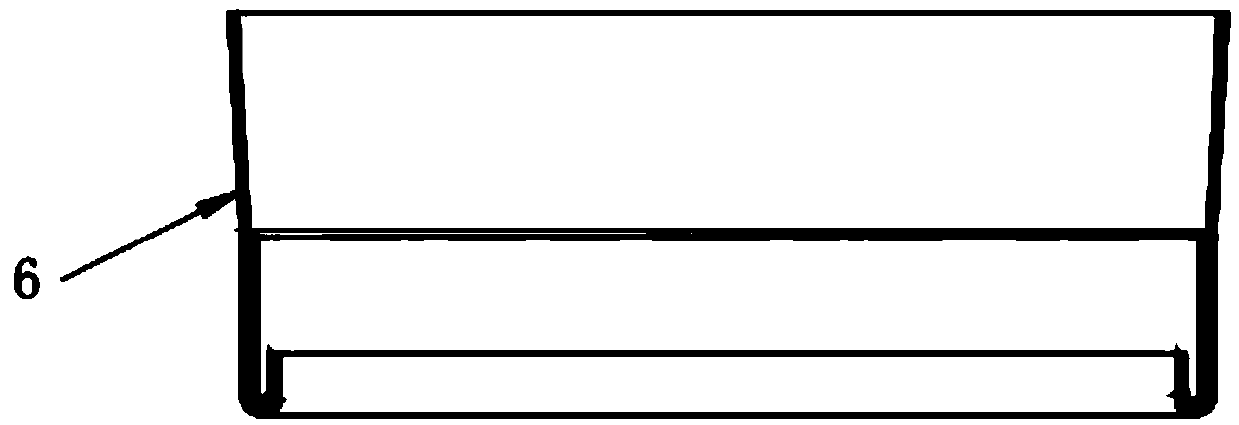

[0052] Such as Figure 1 to Figure 6 As shown, the button-type miniature rechargeable lithium battery structural assembly includes an upper casing 1, a lower casing 2, and a rubber ring 6; the upper casing 1 is buckled in the lower casing 2, and the upper casing 1 and the lower casing The side walls of 2 are sealed by a rubber ring 6.

[0053] The wall thickness of the rubber ring 6 is gradually thicker along the installation direction, and the gradual wall thickness of the rubber ring is 0.01-0.1 mm.

[0054] The upper shell 1 and the lower shell 2 both include a cup body 8. The cup mouth of the cup b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com