An online maintenance device and method for battery packs at feeder terminals

A battery pack and feeder terminal technology, which is used in the repair/maintenance of secondary batteries, secondary batteries, circuits, etc., can solve the problems of power distribution loss of distribution network lines, maintenance of battery packs, failure of feeder automation functions, etc., to ensure stability. The effect of operation, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

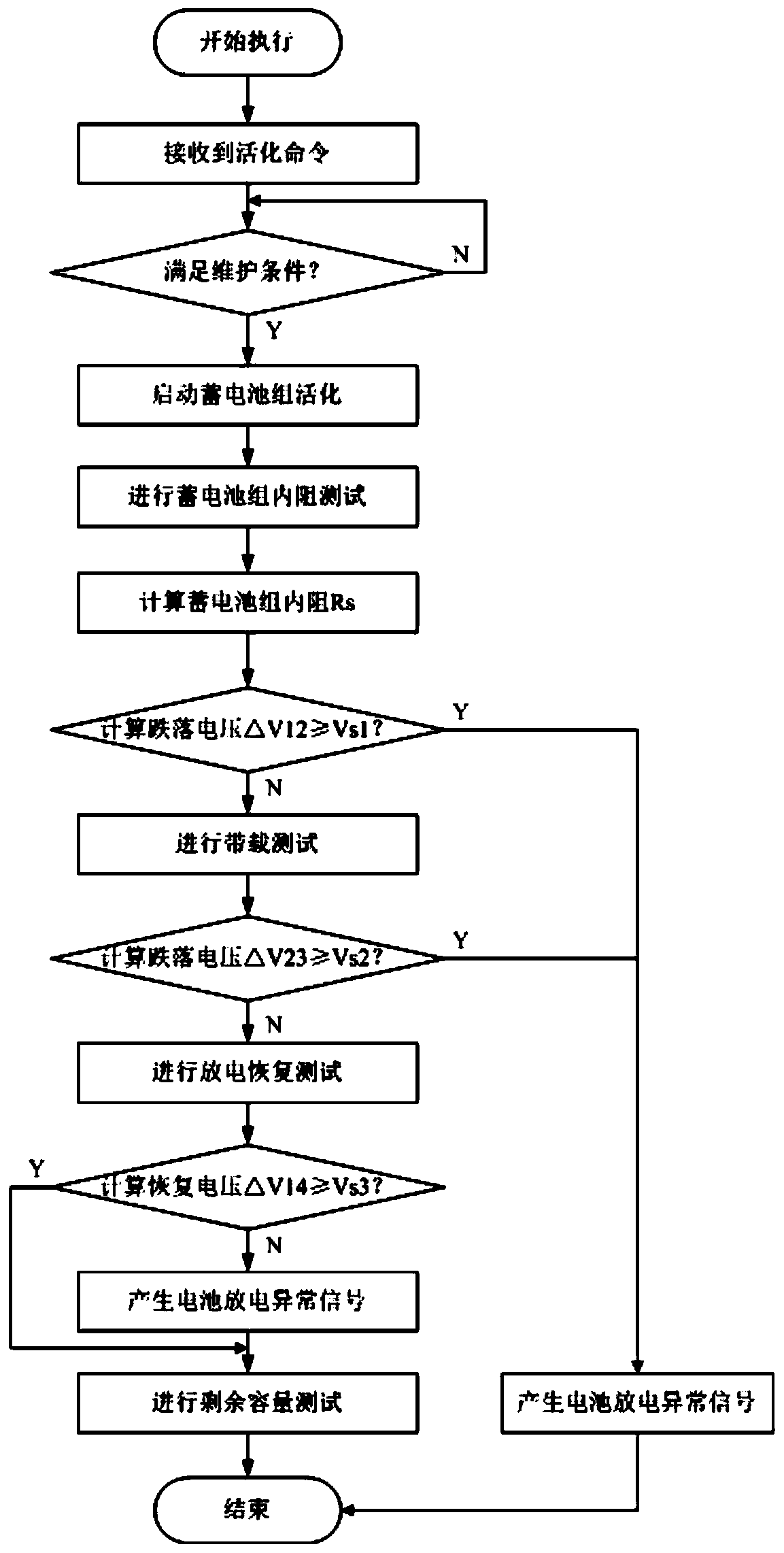

[0021] The present invention is described in detail below in conjunction with the accompanying drawings.

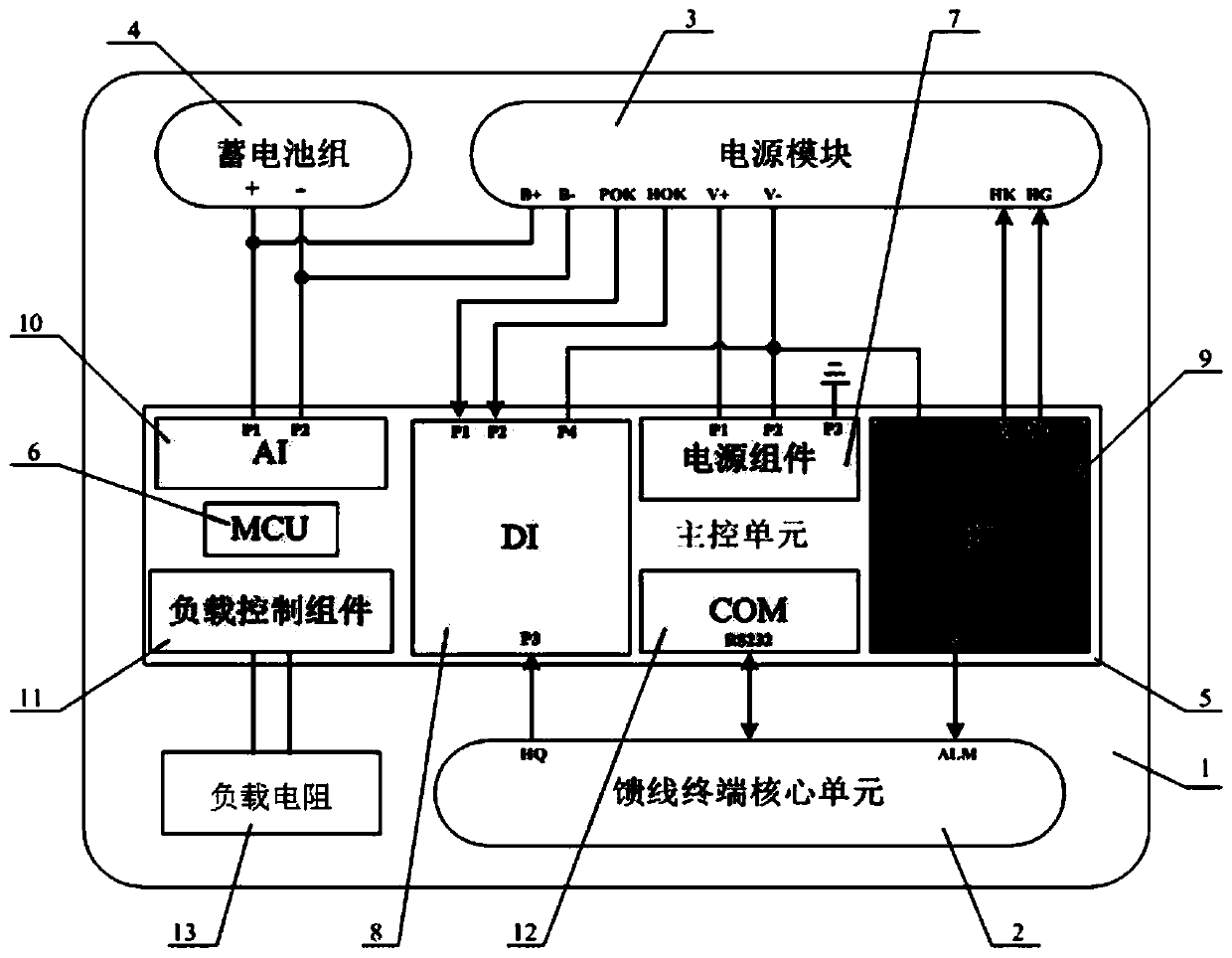

[0022] refer to figure 1 , an online maintenance device for battery packs at feeder terminals according to the present invention includes a main control unit 5 and a load resistor 13 . The main control unit 5 includes a micro control unit (MCU) component 6 , a power supply component 7 , a digital input component 8 , a digital output component 9 , a battery voltage monitoring component 10 , a load control component 11 and a communication component 12 .

[0023] The port P1 of the power supply component 7 is connected to the V+ output of the power module 3, the port P2 is connected to the V- output of the power module 3, and the port P3 is connected to the PE grounding bolt to obtain power from the power module 3 to provide working power for the main control unit 5.

[0024] The port P1 of the digital input component 8 is connected to the POK port of the power supply modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com