A Distributed Heat Storage System

A heat storage system, distributed technology, applied in the direction of cooling/ventilation/heating transformation, using liquid cooling for modification, etc., can solve the problems of adjacent space restrictions, achieve the goal of increasing heat storage rate, extending heat conduction path, and improving flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

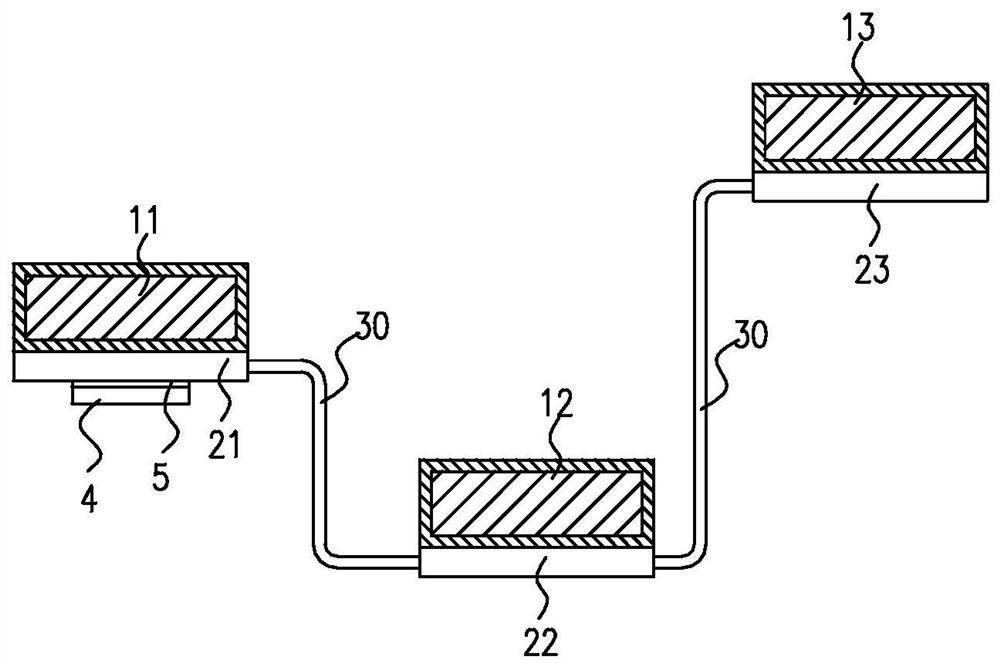

[0023] In the embodiment of the present invention, the phase change material (PCM) is used to absorb the heat generated during the operation of the internal components of the electronic equipment, and the stored heat is proportional to the volume of the phase change material that can be filled. As electronic equipment is becoming more and more compact, when PCM is required for heat storage in engineering, there is no space for heat storage devices around high-power devices in many electronic equipment, or the space provided is not enough to meet their heat storage needs. In order to solve this problem, the present invention provides a distributed heat storage system, which can make full use of the internal space of electronic equipment, has good heat storage rate, can be flexibly adjusted according to the specific structure of electronic equipment, and has wide adaptability.

[0024] Specifically, the present invention provides a distributed heat storage system, which can make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com