Multi-axis linkage spraying device and spraying method for thermal barrier coating on surface of special-shaped structural member

A multi-axis linkage, thermal barrier coating technology, applied in the direction of the spraying device, etc., to achieve the effect of good coating quality, reduce the limitation of thermal spraying, and avoid the effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

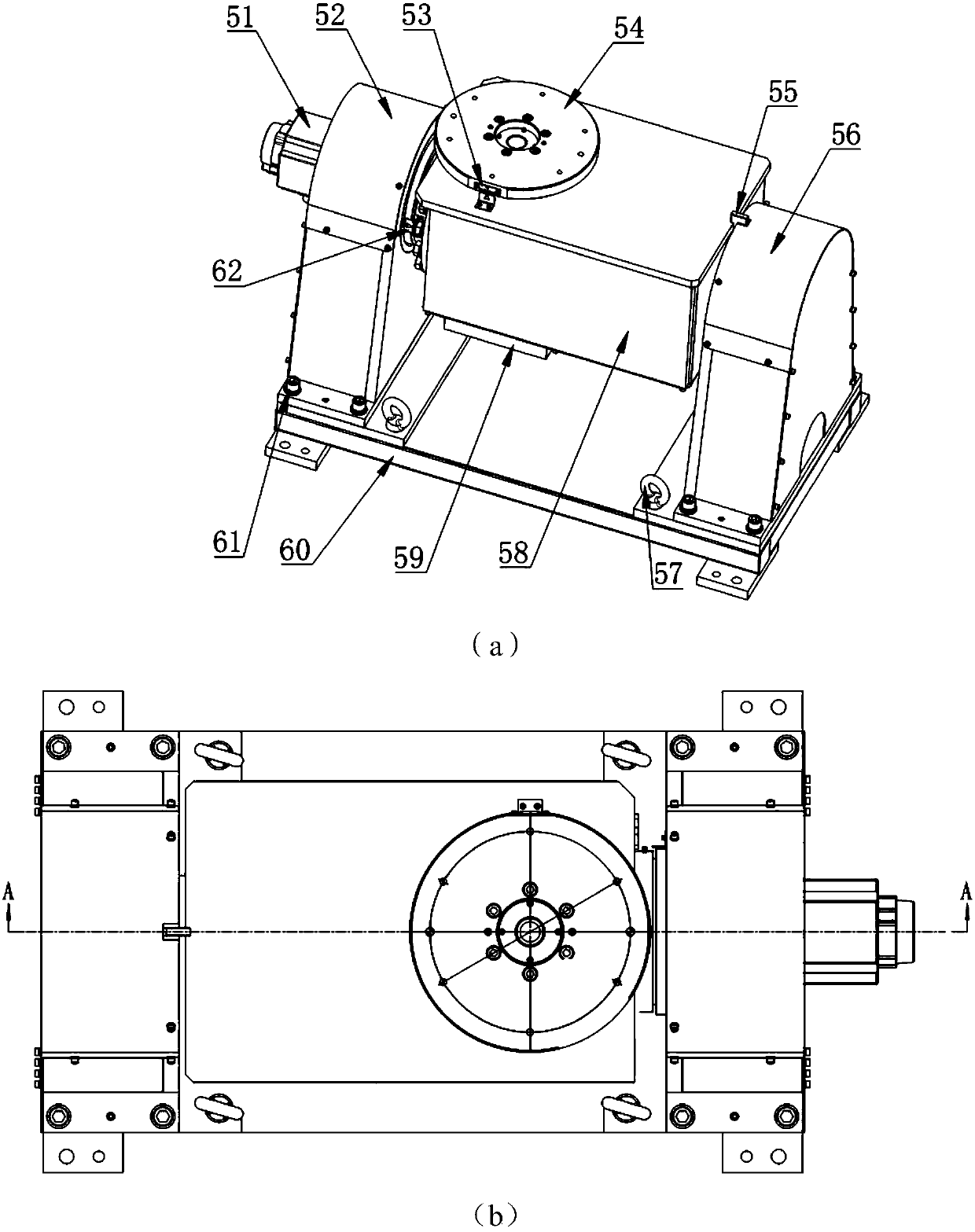

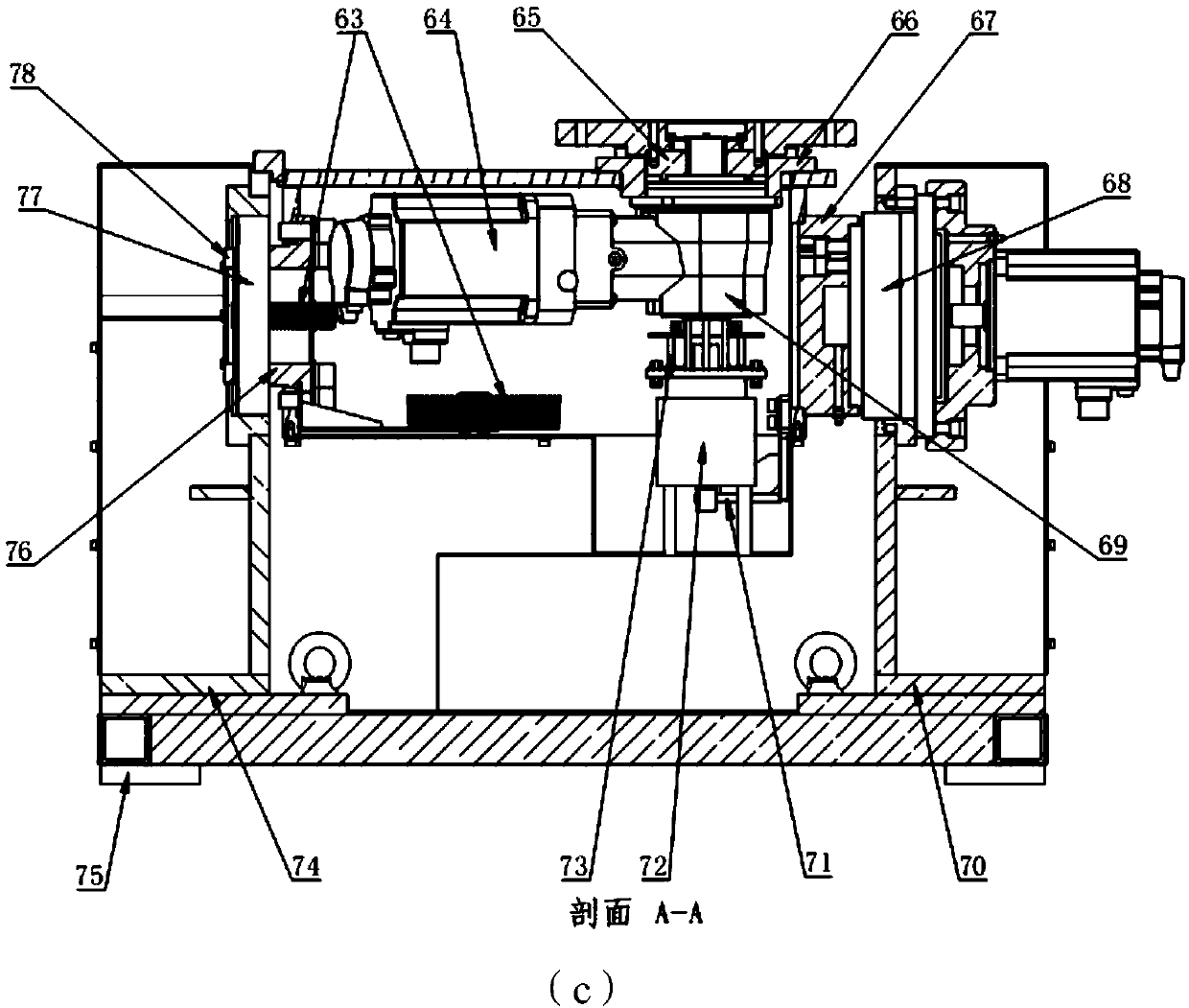

[0033] Such as figure 2As shown, the present invention provides a multi-axis linkage spraying device for thermal barrier coatings on the surface of special-shaped structural parts, including a three-dimensional modeling unit 10, a multi-axis linkage plasma spraying unit 20 and a thickness monitoring and feedback unit 30; the three-dimensional modeling unit 10 It is used to establish the 3D mesh model of the external shape of the workpiece 40 to be sprayed. The external shape of the workpiece to be sprayed is scanned and photographed in 3D, and the point cloud data is obtained after multiple scans. The public reference points are used to piece together and fit to generate high-quality Three-dimensional grid model; the multi-axis linkage plasma spraying unit 20 is used to carry out the profiling spraying track preparation according to the exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com