Casting process for heavy truck differential housing

A technology of automobile differential gear and casting process, which is applied in the field of casting processing, can solve the problems of large shrinkage tendency and high cost of castings, and achieve the effects of precise feeding, reducing cleaning costs, and reducing casting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

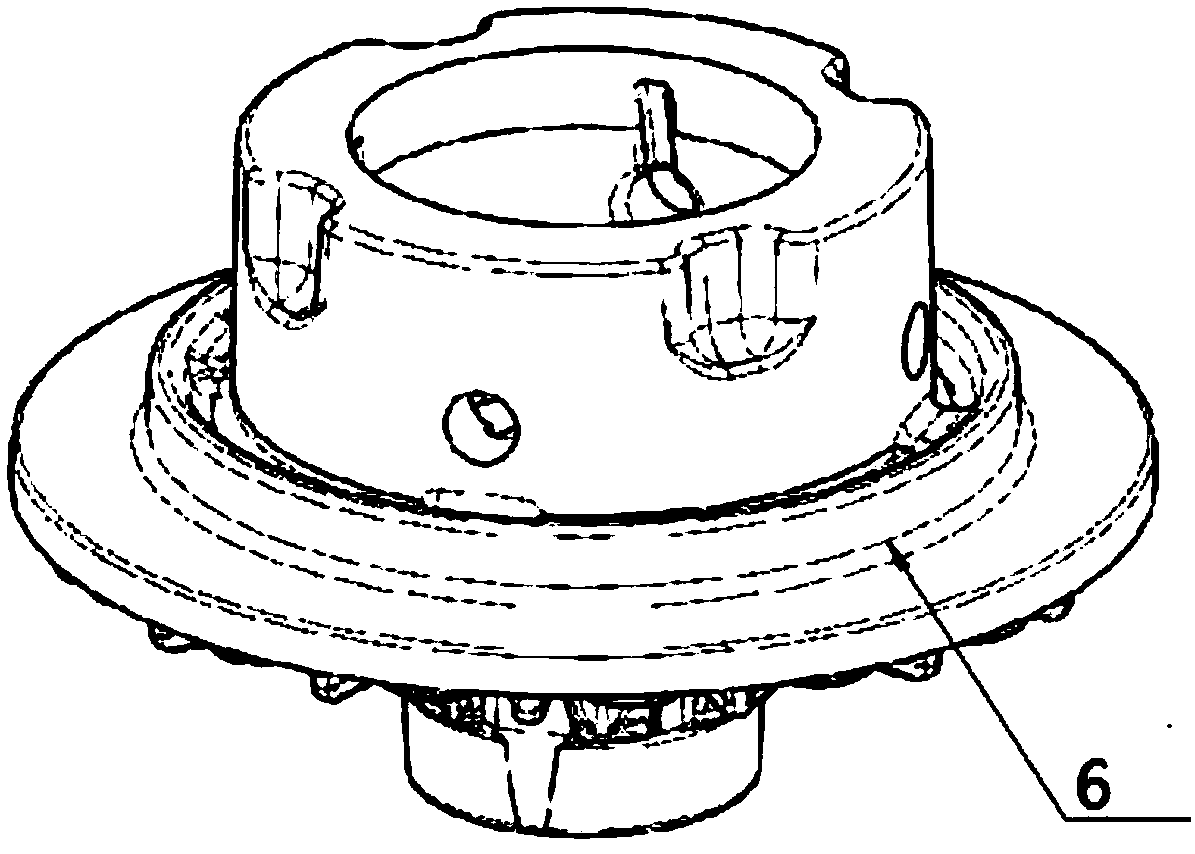

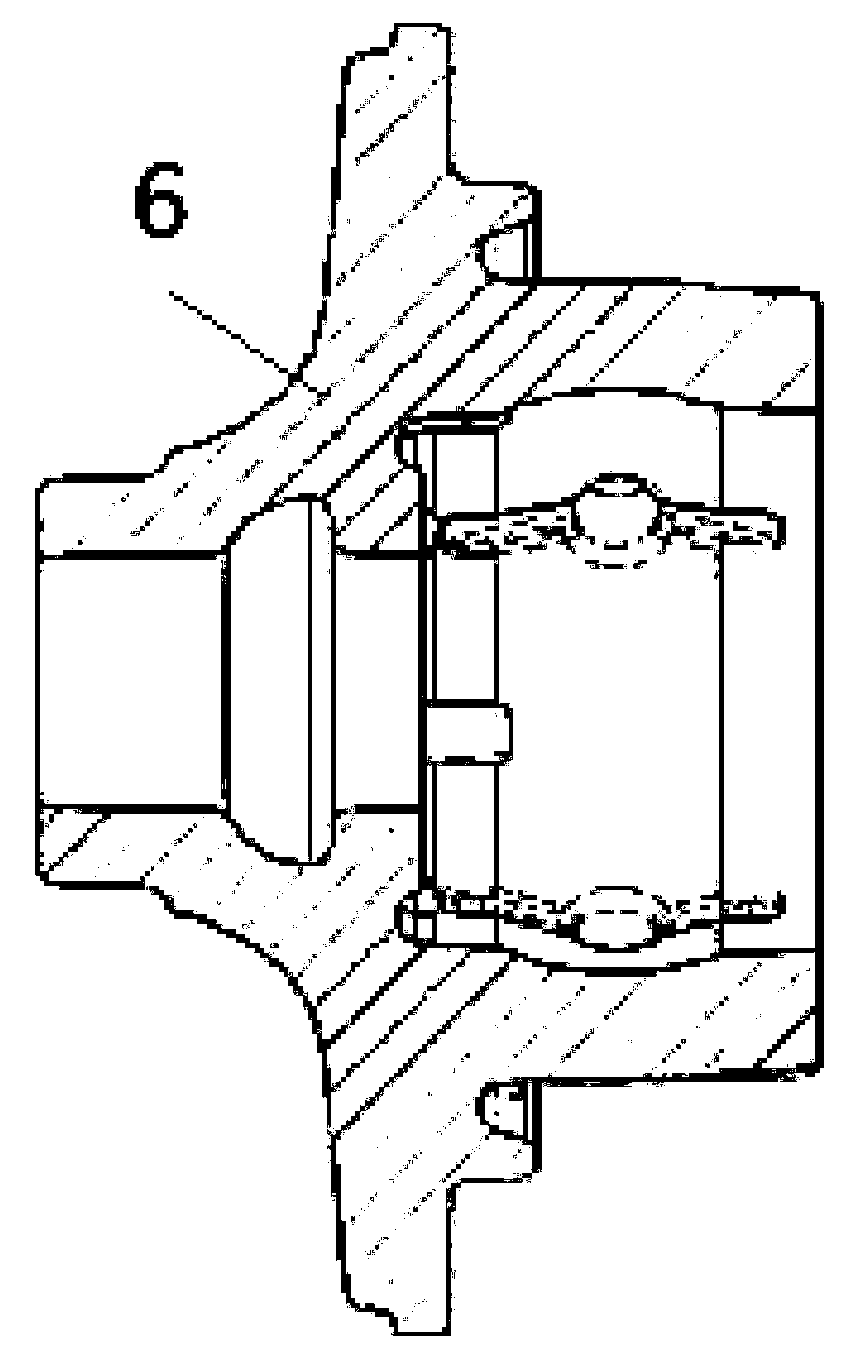

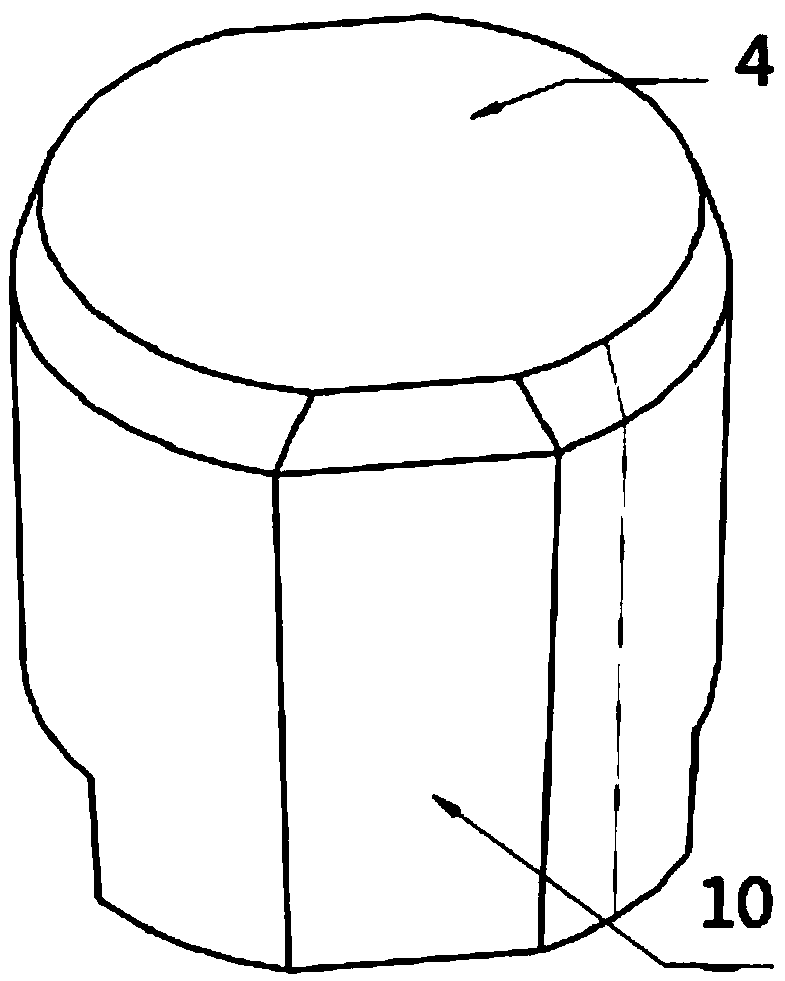

[0026] Attached below Figure 1-10 The present invention is described in further detail.

[0027] During specific implementation: a casting process for a heavy-duty truck differential housing, including a pouring system 1, a sand cavity, a sand core 3, a riser 5, and a thermal insulation and heating riser sleeve 4; the sand core 3 is fixedly installed on In the sand mold cavity 2, the pouring system 1 is provided with at least one ingate 11, the end of the ingate 11 is fixedly connected with the sand mold cavity 2, and the upper surface of the sand core 3 is concave to form a groove, The riser 5 is arranged in the groove, the upper end of the riser 5 is located above the sand core 3, the riser 5 includes at least two independently arranged riser units, and the lower end of the riser unit is one At least one riser neck 7 is provided on each side, and the heat preservation and heating riser cover 4 includes at least two independent cavities, and the heat preservation and heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com