Honeycomb core veneer with staggered reinforcing ribs and manufacturing method thereof

A manufacturing method and technology for reinforcing ribs, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve problems such as compressive strength, low shear strength, thin-walled cells are prone to instability, and cell deformation , to achieve a breakthrough in compressive strength, expand the scope of application, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

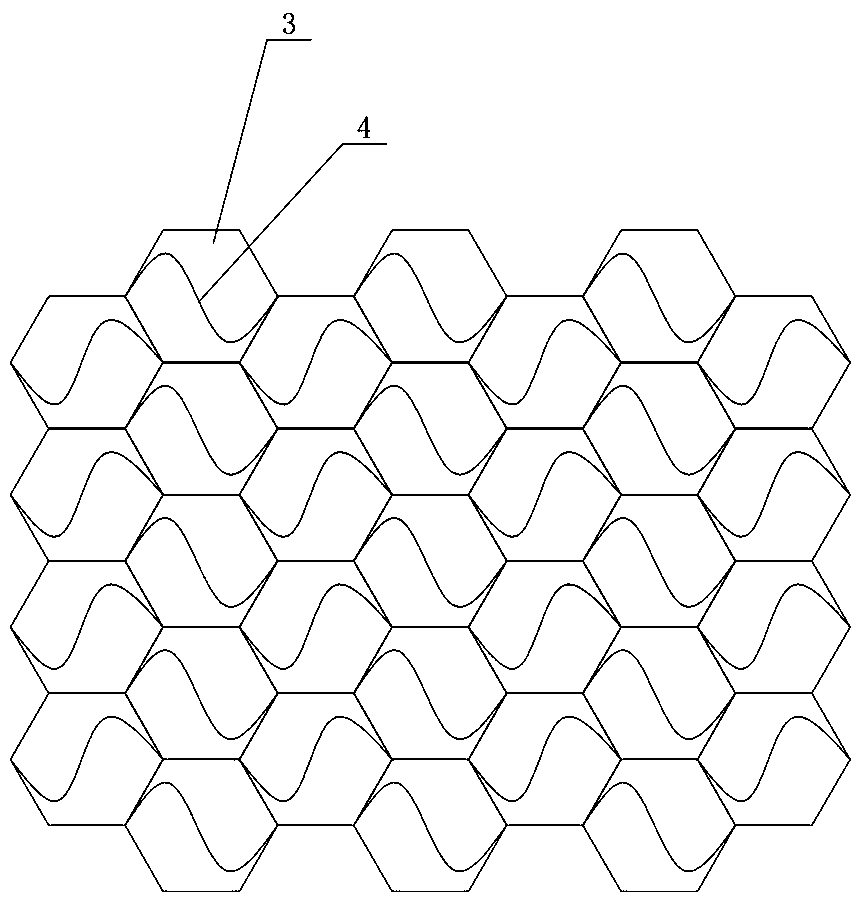

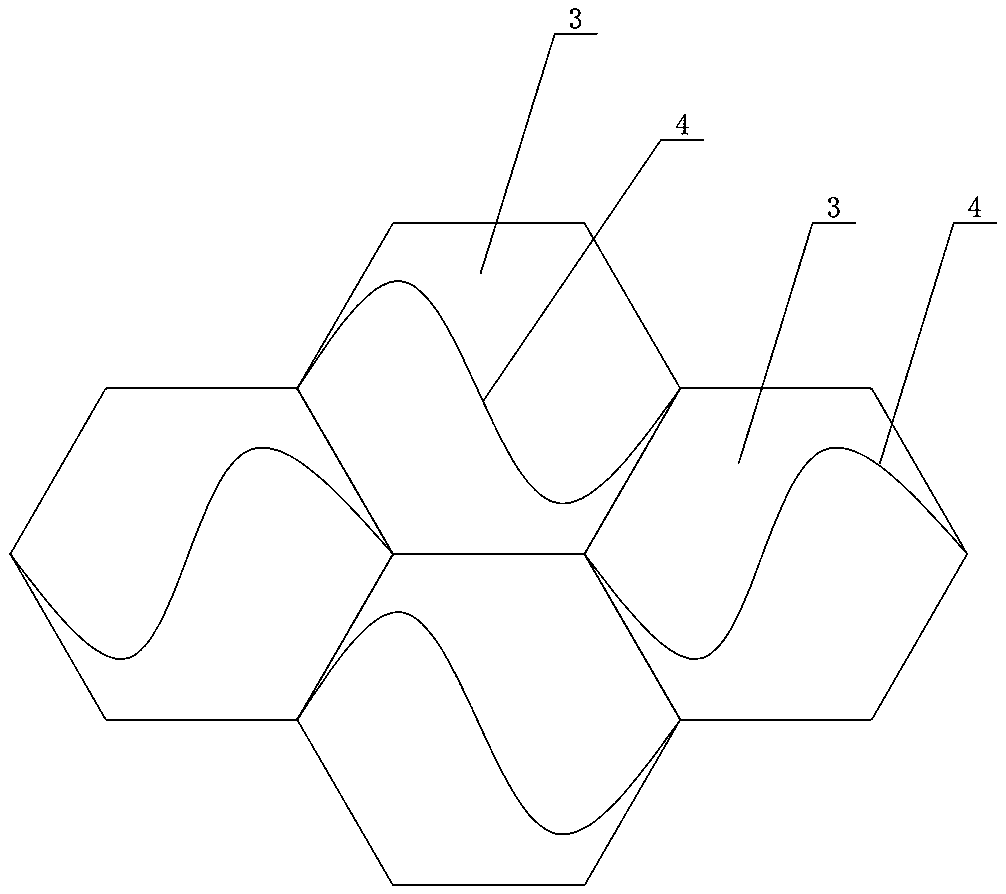

[0057] Figure 1 to Figure 6 It shows the first embodiment of the rib interlaced honeycomb core plate of the present invention (glue on one side), the core plate includes at least two original base bands 1, and a reinforcing band 2 is arranged between each original base band 1, Adjacent primordium strips 1 and reinforcing strips 2 are bonded at even intervals, and are pulled apart to form a honeycomb structure with a plurality of hexagonal unit holes 3. Each hexagonal unit hole 3 has a reinforced The S-shaped reinforcing ribs 4 formed by the belt 2, and the S-shaped reinforcing ribs 4 formed on the adjacent reinforcing belts 2 are arranged in a staggered manner with opposite twisting directions. In this structure, a honeycomb structure with a plurality of hexagonal unit holes 3 is formed between each primordium strip 1. Compared with traditional corrugated cardboard, wood, foam plastic and other materials, it has sound absorption and heat insulation, and the process is simple....

Embodiment 2

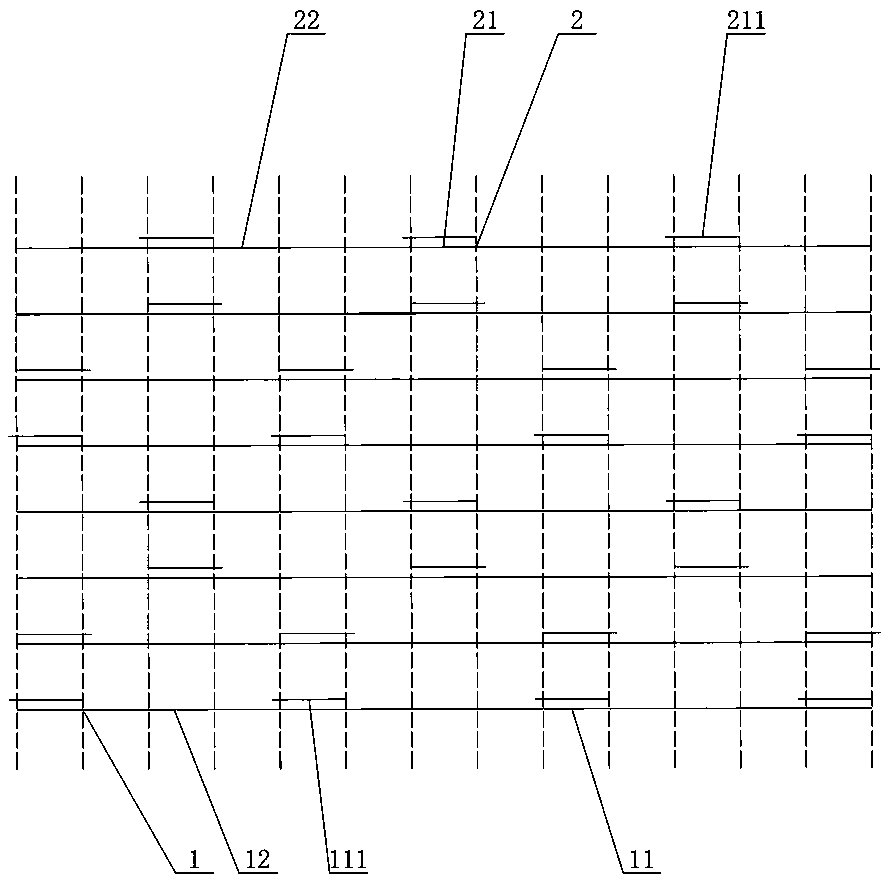

[0086] Such as Figure 8 to Figure 9 As shown, in the second embodiment of the present invention (double-sided glue coating), the two sides of each second bonding edge 21 are provided with a second bonding area 211, and each second bonding The area 211 extends to the second forming edge 22 in the same direction adjacent to it, and the second bonding area 211 on the adjacent two sides extends in the opposite direction. The second bonding area 211 is connected to the first bonding edge 11 and part of the first The profiled edge 12 is bonded. In this structure, each second bonding area 211 extends to the second forming side 22 adjacent to it in the same direction, and the second bonding areas 211 on the adjacent two sides extend in opposite directions. A bonding side 11 and a part of the first forming side 12 are bonded, and the setting of the extension section makes it easier to form a stable S-shaped rib 4 when it is pulled apart to both sides after bonding to ensure the compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com