Automatic PCB cleaning and detecting device

A PCB board, automatic cleaning technology, applied in cleaning methods and utensils, cleaning methods using tools, conveyors, etc., can solve problems such as fatigue, affecting work efficiency, PCB board cleaning quality, and affecting the accuracy of PCB inspection results. , to achieve the effect of improving accuracy, improving cleaning efficiency and cleaning quality, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

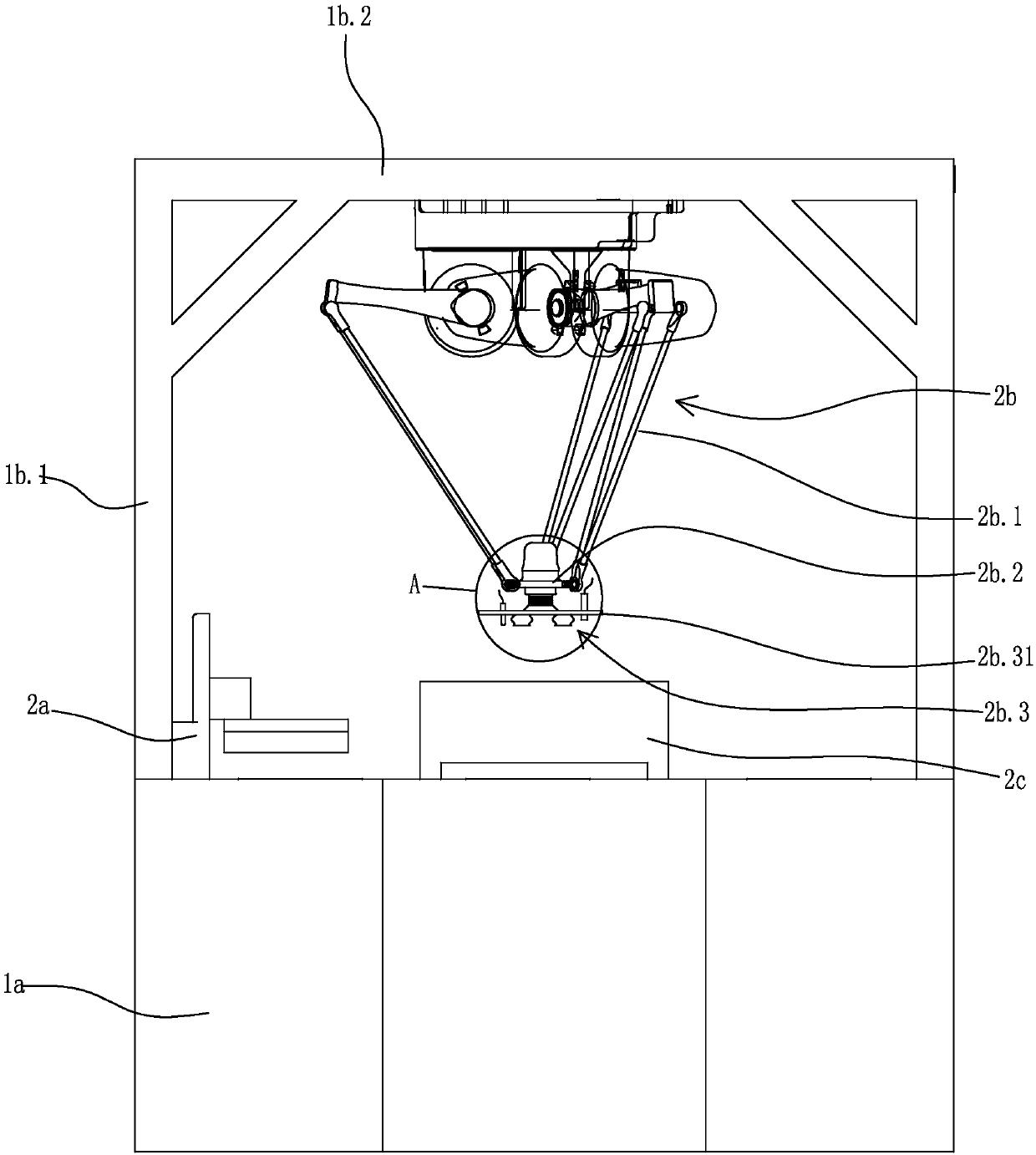

[0050] Specific embodiment one: as figure 1 , figure 2 As shown, a PCB board automatic cleaning and testing equipment includes a machine table, a spider hand robot 2b, a PCB board cleaning device 2a and a PCB testing instrument 2c.

[0051] The machine platform includes a general worktable 1a and a frame arranged on the general workbench. The frame includes a side support 1b.1 and a top support 1b.2 arranged on top of the side support.

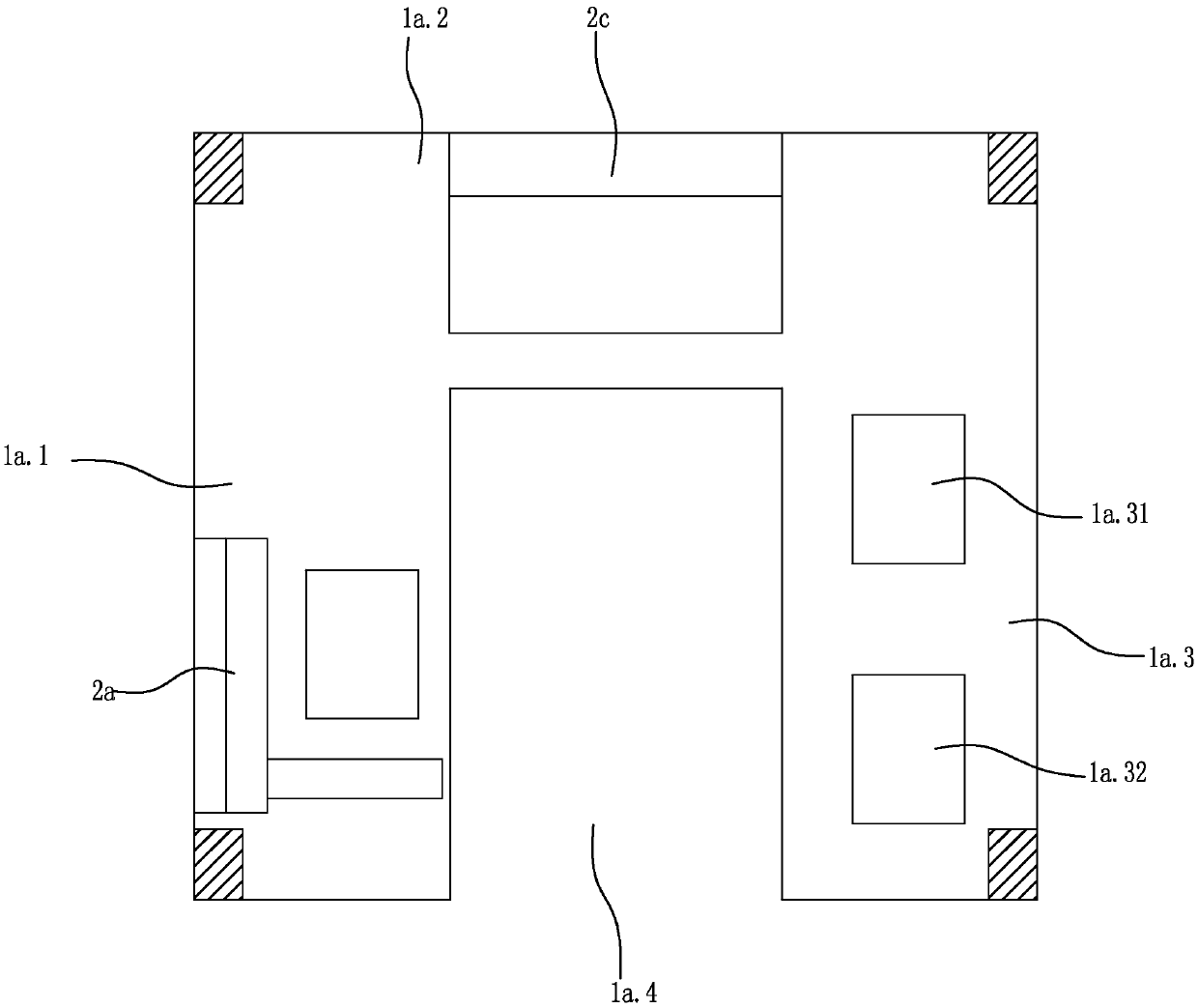

[0052] The general workbench includes a cleaning workbench 1a.1, a detection workbench 1a.2 and an output workbench 1a.3. The cleaning workbench, the detection workbench and the output workbench are connected in sequence. The cleaning workbench, detection workbench and output workbench are distributed in a U shape. The space between the cleaning workbench, the detection workbench and the output workbench forms the operation space 1a.4. The output workbench is provided with qualified product output station 1a.31 and unqualified product o...

specific Embodiment 2

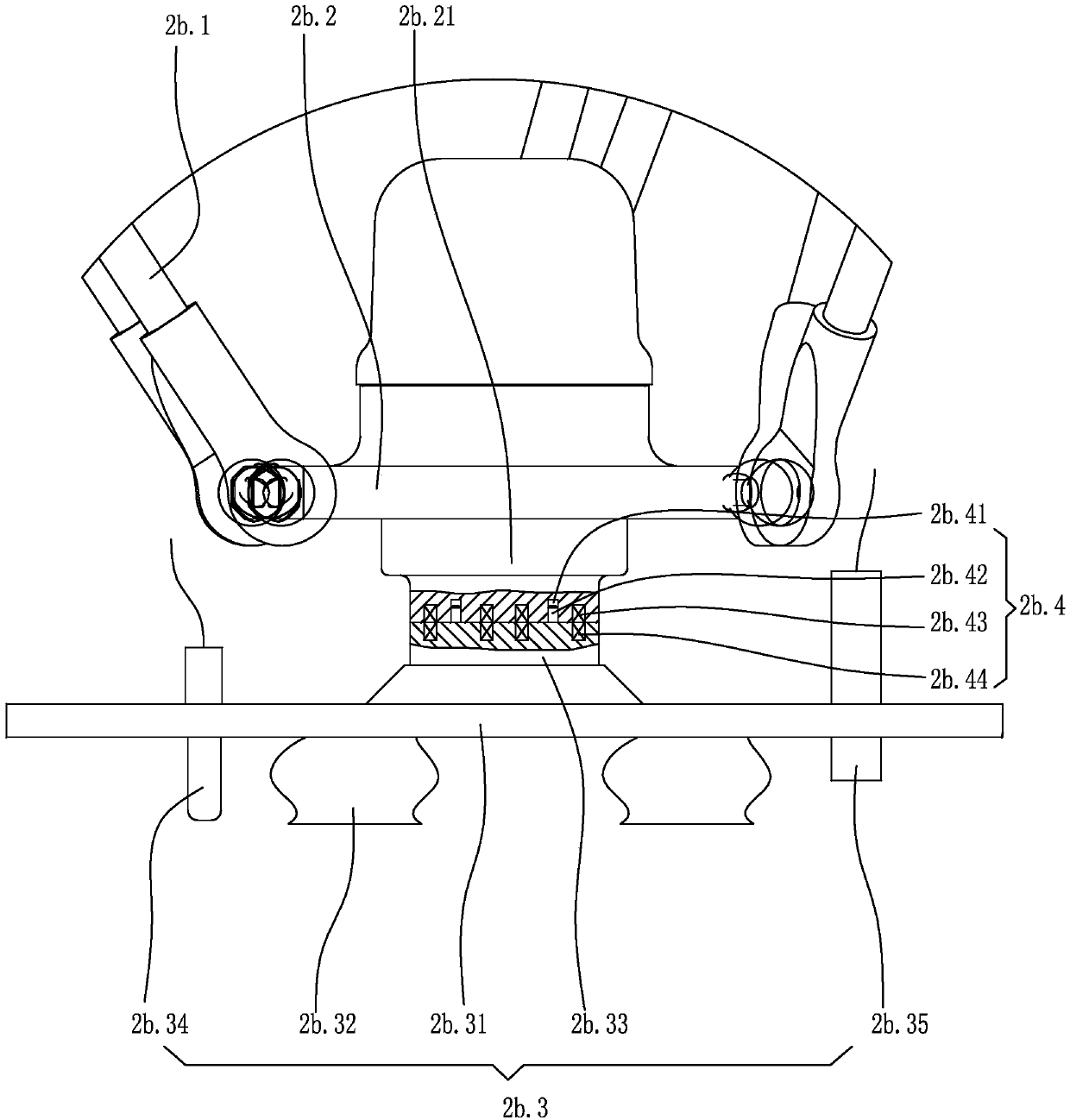

[0084] Specific embodiment two: the specific structure of this embodiment is with reference to specific embodiment one, and its difference is: as figure 2 As shown, the PCB board adsorption device includes a contact sensor 2b.34 provided on the conveying board. The controller is electrically connected with the contact sensor. When the spider hand robot controls the mounting plate and the PCB adsorption device to move down and absorb the PCB board, when the contact sensor touches the PCB board to be adsorbed, the controller controls the spider hand robot to stop the mounting plate from moving down, and at this time , The suction cup of the PCB board adsorption device absorbs the PCB board; in this way, the excessive downward movement of the PCB board adsorption device can be avoided, causing the PCB board to be crushed.

specific Embodiment 3

[0085] Specific embodiment three: the specific structure of this embodiment refers to specific embodiment one or specific embodiment two, and its difference is: as figure 2 As shown, the PCB board adsorption device includes a laser distance measuring sensor 2b.35 set on the conveying board. The controller is electrically connected with the laser ranging sensor. When the spider hand robot controls the mounting plate and the PCB adsorption device to move down and absorb the PCB board, the laser ranging sensor can detect the distance between the carrier board and the PCB board to be adsorbed. When the carrier board is close to the PCB board to be adsorbed At this time, the controller controls the spider hand robot to reduce the downward movement speed of the mounting plate and the PCB board adsorption device, so as to avoid excessive downward movement of the PCB board adsorption device and cause the PCB board to be crushed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com