Gel breaking agent for preventing slurry from falling to ground and gel breaking method for waste drilling fluid

A technology of discarded drilling fluid and gel breaker, which is applied in the field of drilling, can solve the problems of drilling fluid stability impact, non-compliance with national standard discharge requirements, and large cost increment, etc., to achieve a simple and practical gel breaking method, saving manpower and material resources The long-term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

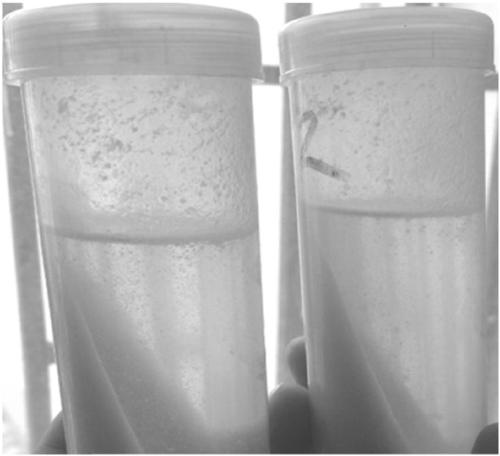

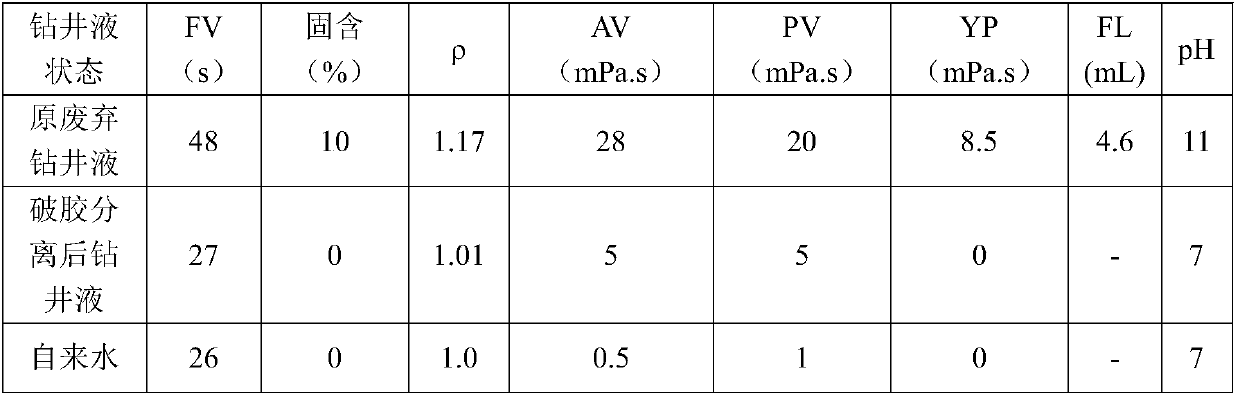

[0028] The gel breaker in this example is composed of hydrochloric acid and polyacrylamide particles; the mass fraction of hydrochloric acid is 25%; the polyacrylamide particles are partially hydrolyzed polyacrylamide potassium salt commonly used in drilling, with a molecular weight of 3 million to 5 million.

[0029] The gel-breaking method of the waste drilling fluid in the present embodiment is:

[0030] (1) Configure water-based drilling fluid according to mass percentage: clear water + 4% sodium bentonite + 0.2% Na 2 CO 3 +0.3%K-HPAN+1%NH 4 -HPAN + 0.8% LV-CMC + 3% sulfonated bitumen + 1% sulfonated lignite + 1.5% sulfomethyl phenolic resin + 25% barite, the resulting drilling fluid has a Martens viscosity of 48 seconds and does not need to be dilute with water;

[0031] (2) Add 1.2 g of polyacrylamide particles into 400 mL of drilling fluid, and stir for 30 minutes at a stirring speed of 8000 r / min. The measured pH value of the drilling fluid is 11;

[0032] (3) Acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com