Surface water defluorination process based on carbon nanotube three-dimensional electrode

A three-dimensional electrode, carbon nanotube technology, applied in the fields of water pollutants, water/sewage treatment, water/sewage treatment equipment, etc., can solve the problems of ineffective removal of fluoride, secondary pollution of water bodies, etc., and achieve good chemical stability performance, fast regeneration, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

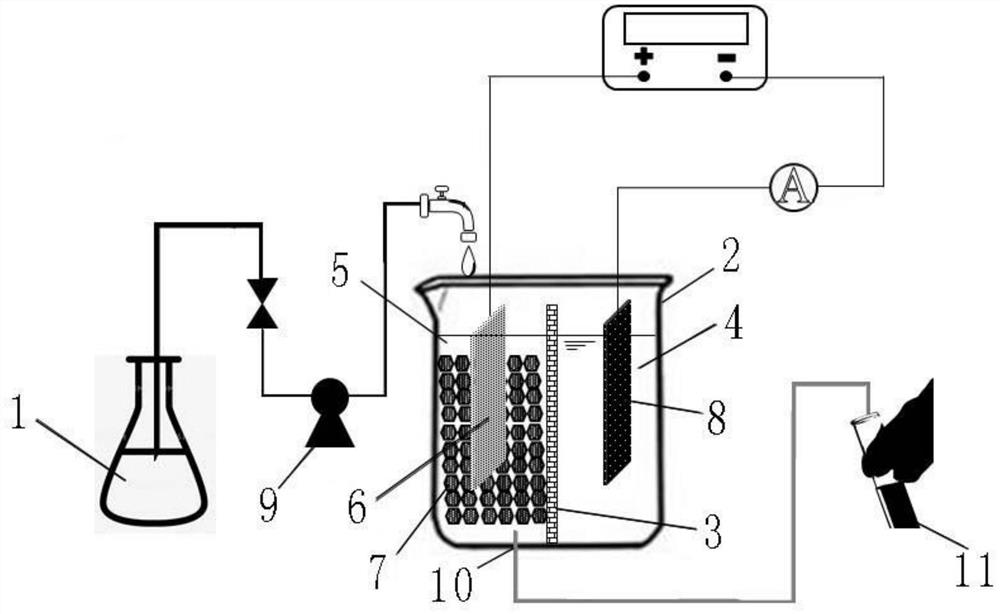

Method used

Image

Examples

Embodiment 1

[0060] A method for preparing a fluoride adsorption three-dimensional electrode, comprising the following steps:

[0061] S101, preparing powdered carbon nanotubes;

[0062] S102, using the powdered carbon nanotubes prepared in S1 to prepare sheet electrodes;

[0063] S103, preparing a carbon nanotube three-dimensional electrode material.

[0064] Further, the specific operation of said S101 is:

[0065] Heating nitric acid to 100°C-110°C, mixing with industrial grade carbon nanotubes to remove impurities;

[0066] Washing the carbon nanotubes with distilled water until the pH of the washed water is neutral;

[0067] Place it in an oven at 80°C for 12 hours, take it out and grind it into powder for later use.

[0068] Further, the purity of the nitric acid is 60%, and the purity of the industrial-grade carbon nanotubes is 98%.

[0069] Further, the specific operation of S102 is: mix 0.45-0.55g of carbon nanotubes with 15-25mL of ethanol, add 0.15-0.25mL of 75% PTFE soluti...

Embodiment 2

[0075] This embodiment is described on the basis of the above-mentioned embodiment 1, and the similarities with the above-mentioned embodiment 1 will not be repeated.

[0076] In the process of preparing powdered carbon nanotubes in this example, nitric acid was heated to 105°C, and the purity of industrial grade carbon nanotubes was 98%;

[0077] When preparing sheet electrodes, mix 0.5 g of powdered carbon nanotubes with 20 mL of ethanol, add 0.2 mL of 75% PTFE solution, and ultrasonicate for 30 minutes.

Embodiment 3

[0079] This embodiment is described on the basis of the foregoing embodiment 1 or 2, and the similarities with the foregoing embodiments will not be repeated.

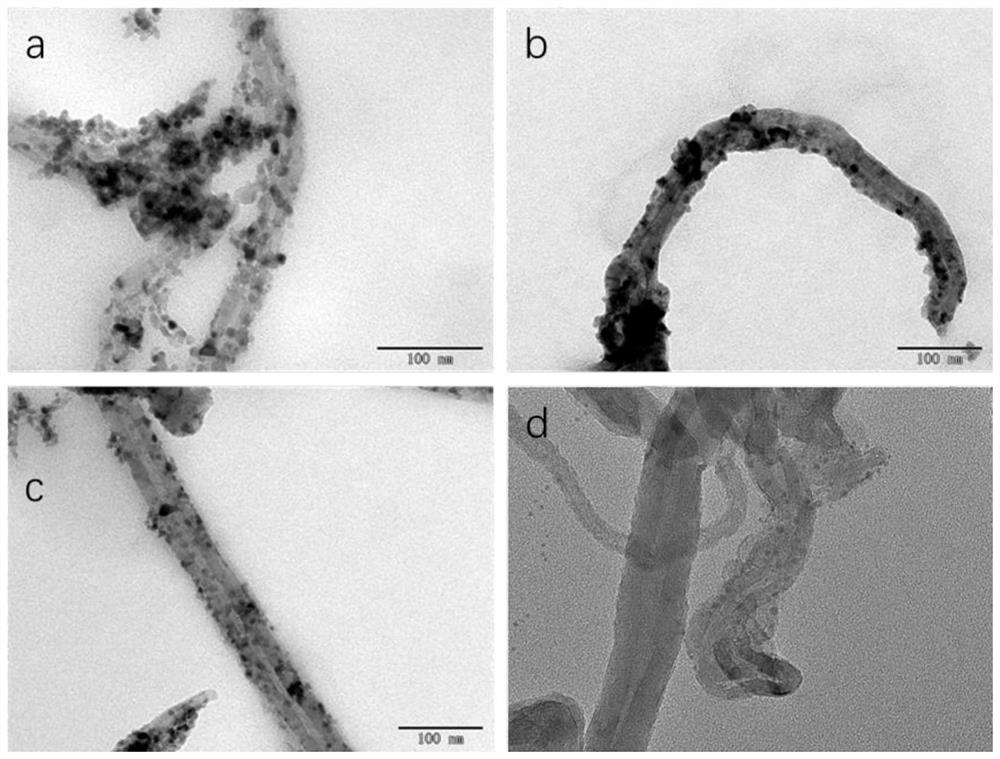

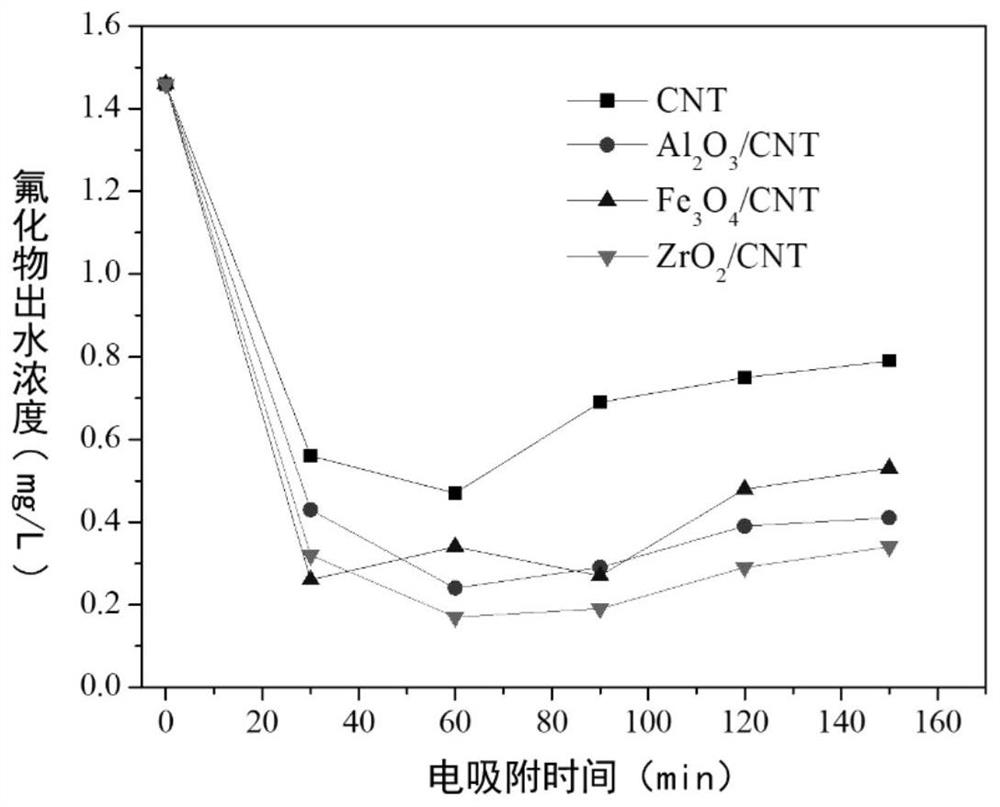

[0080] This embodiment mainly introduces the use of Al on the surface of carbon nanotubes 2 o 3 Modification is carried out to increase the adsorption capacity of the three-dimensional electrode for fluoride.

[0081] The method for modifying the surface of carbon nanotubes with metal oxides specifically includes:

[0082] Mix 0.6g of carbon nanotubes with 0.004-0.006 moles of Al 2 (NO 3 ) 3 9H 2 O was dissolved in 50 mL of ethylene glycol, ultrasonicated for 1 h, and magnetically stirred for 8-12 h; then, calcined at 500 °C for 2 h in a tube furnace under a nitrogen atmosphere to prepare Al 2 o 3 Modified carbon nanotubes, wherein the ratio of metal / carbon atoms is 10% to 15%.

[0083] The beneficial effect that this embodiment obtains:

[0084] This embodiment introduces metal oxide-modified carbon nanotubes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com