Magnetic-guide self-propelled micro/nano motor based on gamma-Fe2O3/MnO2 and preparation method of micro/nano motor

A micro-nano motor, -fe2o3 technology, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc., can solve problems such as not seen, achieve simple preparation process, excellent adsorption performance and recycling performance, The effect of common and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

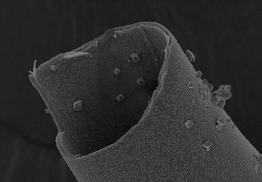

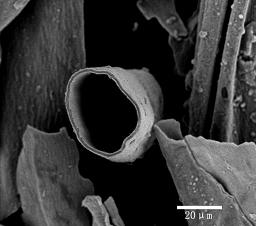

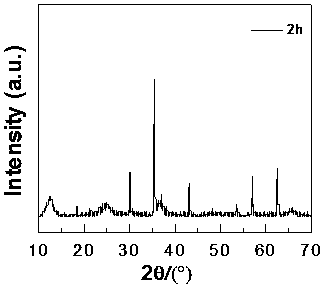

Embodiment 1

[0027] Dissolve 0.03 mol of ferric chloride and 0.015 mol of ferric chloride in 50 mL of deionized water, put in kapok fiber and heat at 60°C for 3 hours, take out the kapok and wash it with deionized water for 2-3 times, put it into freeze-drying box dry. Afterwards, the dried samples were sintered under the protection of nitrogen, the temperature was raised to 550 °C at 10 °C / min and kept for 30 min, and the samples were taken out after cooling down to room temperature. Take 4.5 mg of the sintered sample and place it in 25 mL deionized water for ultrasonication to disperse the sintered sample in the solution, then add 11.06 mg of potassium permanganate and stir to dissolve, transfer it to a 50 ml polytetrafluoroethylene hydrothermal reaction kettle, React at 120 °C for 2 h, and cool to room temperature after the reaction is complete. The product was centrifuged with a high-speed centrifuge at 3000 rpm for 5 min, washed with deionized water, and kept at 60°C for 48 h to obta...

Embodiment 2

[0029] By configuring H 2 o 2 solution into γ-Fe 2 o 3 / MnO 2 The micro-nano motor is placed on an optical microscope for shooting, and an external magnetic field is applied to control the direction of movement of the micro-nano motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com