Track derusting and ice crushing device for railway construction

An ice crushing device and track technology, applied in track, track laying, track cleaning, etc., can solve the problems of track derusting work speed, affecting driving safety, affecting track use, etc., achieving low production cost, reasonable and simple structure, and avoiding troublesome and inconvenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

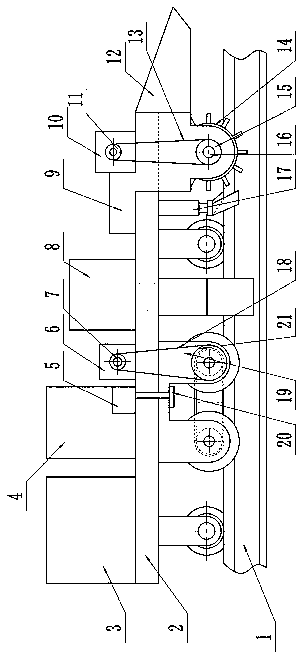

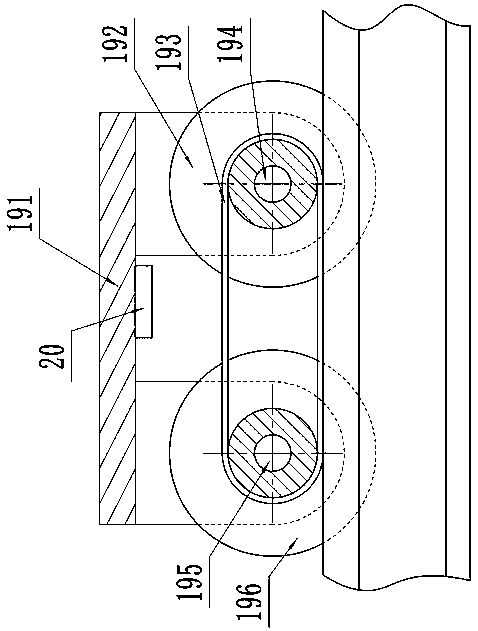

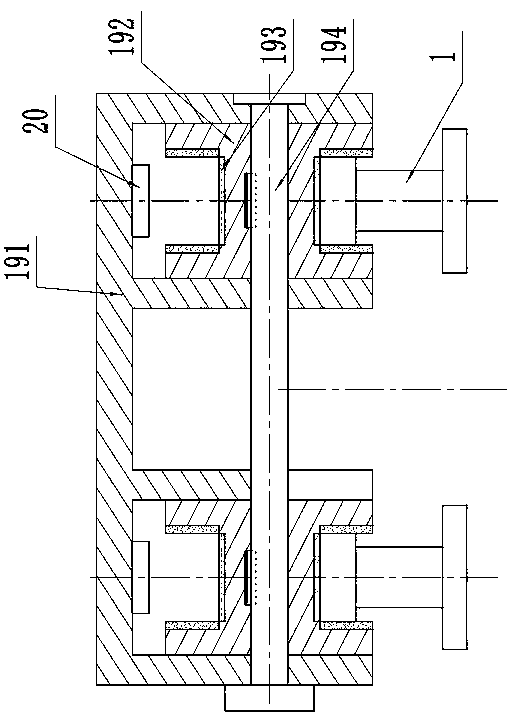

[0025] Such as figure 1As shown, this specific embodiment adopts the following technical solutions: a track derusting and ice breaking device for railway construction, comprising a track 1 and a rail car body 2, the rail car body 2 is movably connected on the track 1, and also includes a diesel generator Machine 3, derusting and antifreezing box 4, water pump 5, motor one 6, driving pulley one 7, ice melting device 8, fixed seat 9, motor two 10, driving pulley two 11, guide plate 12, belt two 13, Ice-crushing blade assembly 14, driven pulley two 15, drive shaft 16, ice scraper 17, belt one 18, derusting device 19, sprinkler head 20 and driven pulley one 21; the diesel generator 3 is fixedly connected to The upper left side of the rail car body 2; the rust removal and antifreeze box 4 is located on the right side of the diesel generator 3, and the rust removal and antifreeze box 4 is fixedly connected to the upper left side of the rail car body 2, and the rust removal and antif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com