A lake cleaning machine

A cleaning machine and water inlet tank technology, which is applied in the cleaning of open water surfaces, construction, water conservancy projects, etc., can solve the problems of equipment failure and eutrophication of water surface cleaning, etc., to achieve convenient transportation and maintenance, and practical application value Good, high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

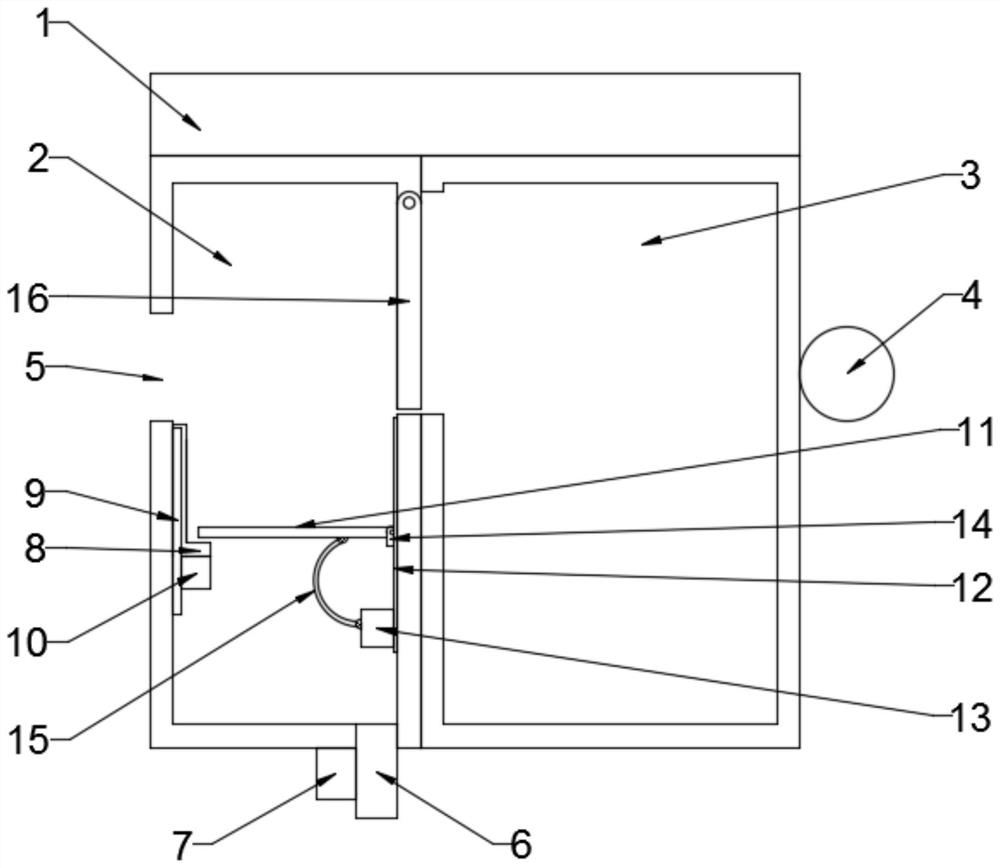

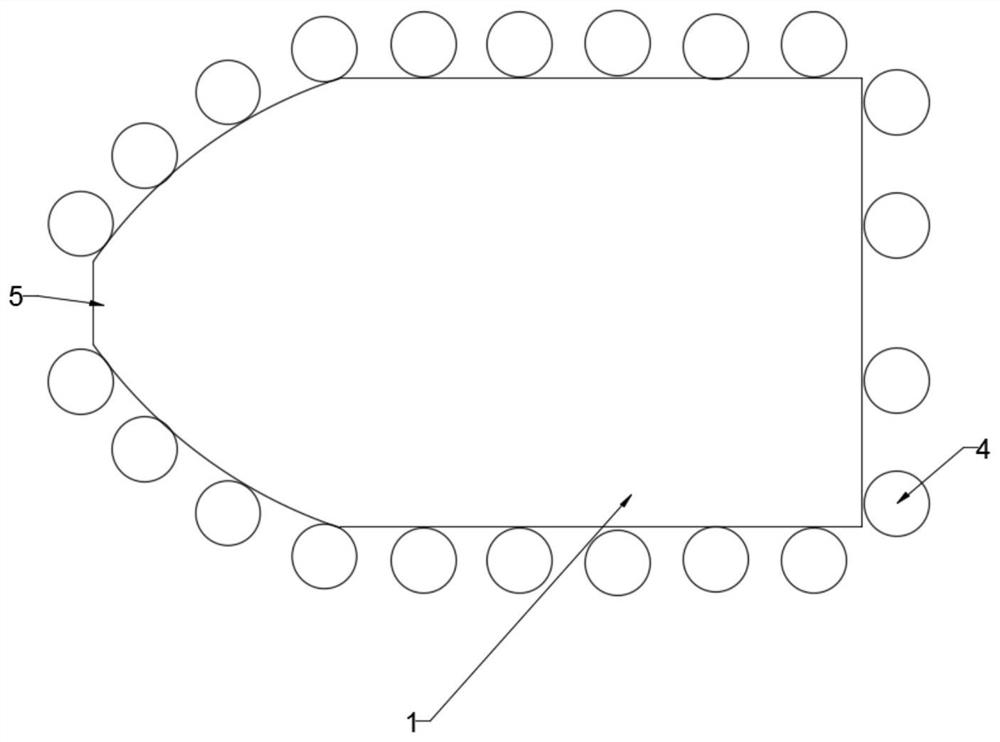

[0034] like Figure 1~3 As shown, the lake cleaning machine provided in this embodiment includes a solar panel 1, a water inlet bin 2, and a storage bin 3, and the water inlet bin 2 and the storage bin 3 are located side by side under the solar panel 1. A circle of air bags 4 are arranged around the water bin 2 and the storage bin 3;

[0035] The water inlet bin 2 is provided with a water inlet 5, a water outlet 6, a water pump 7, a baffle 8, a first slide rail 9, a first motor 10, a trash rack 11, a second slide rail 12, and a second motor 13; The first slide rail 9 is located on both sides of the water inlet 5, the first motor 10 drives the baffle plate 8 to lift up and down on the first slide rail 9, and the bottom end of the baffle plate 8 is bent by 90 ° into shape; the water outlet 6 and the water pump 7 are located below the water inlet chamber 2;

[0036] The second slide rail 12 and the second motor 13 are arranged on the side adjacent to the storage bin 3 in the ...

Embodiment 2

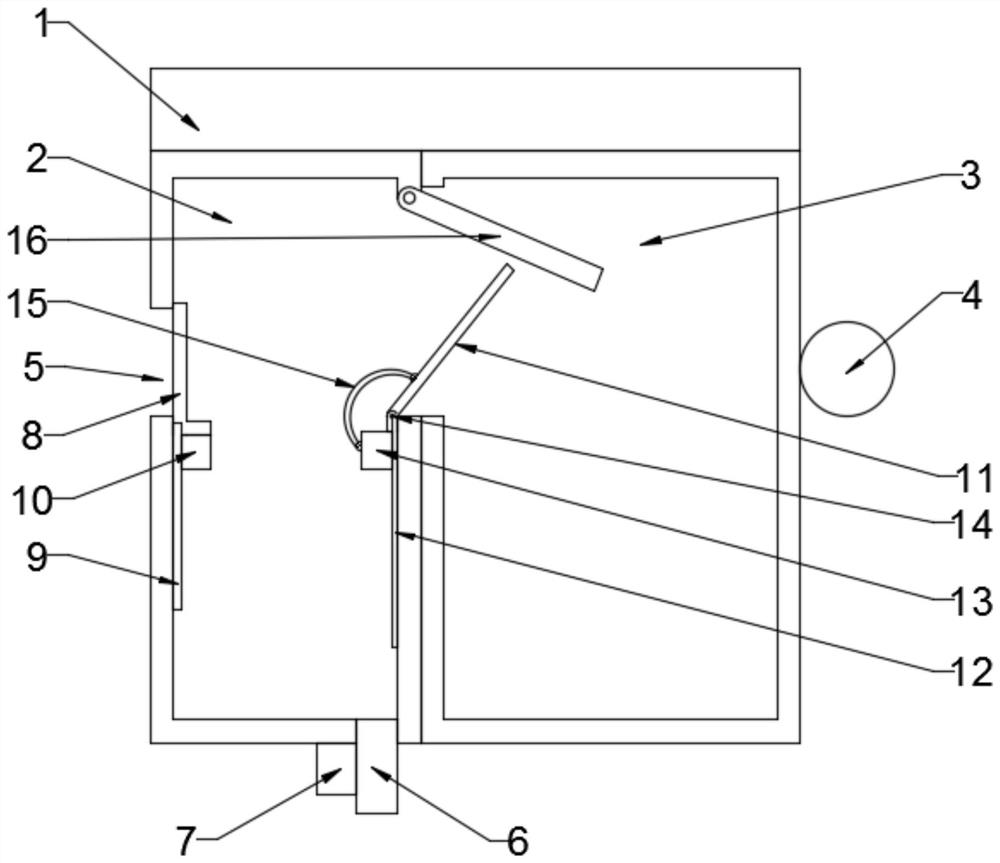

[0042] like Figure 4 As shown, the lake cleaning machine provided in this embodiment has been improved as follows on the basis of Embodiment 1:

[0043] 1. A roller 17 is provided at one end of the trash rack 11 resting on the bottom end of the baffle plate 8, and a push rod 18 is vertically provided on the side of the trash rack 11 close to the roller 17;

[0044] 2. The water inlet 5 is trumpet-shaped;

[0045] 3. An engine 19 and a propeller 20 are arranged below the water inlet bin 2 and the storage bin 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com