A Calculation Method of Asphalt and Aggregate Spalling Rate of Asphalt Pavement

A technology of asphalt pavement and calculation method, which is applied in the field of building materials, can solve problems such as uncontrollable temperature, complicated operation, and high technical difficulty, and achieve the effect of convenient operation, low cost, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

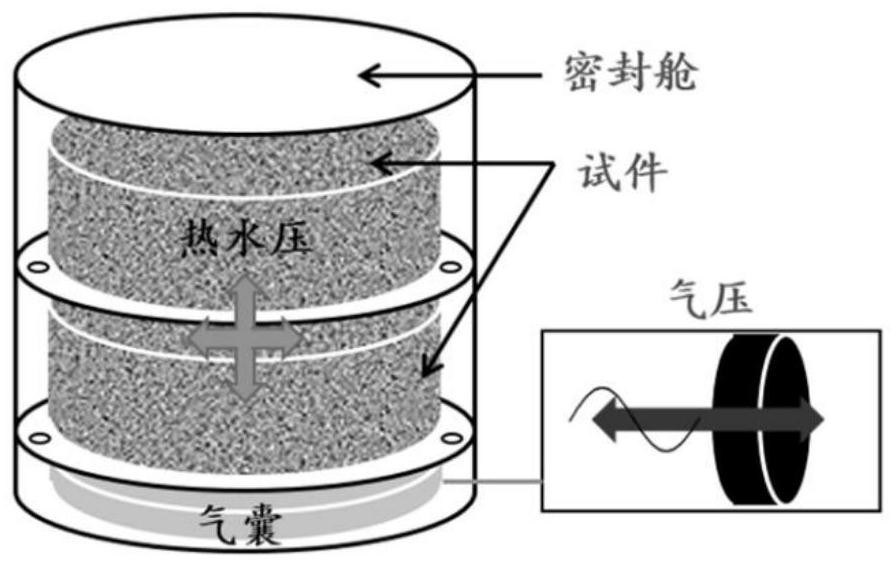

Method used

Image

Examples

Embodiment 1

[0042] In step 1), coarse aggregates with a particle size of 13 mm to 19 mm and a regular shape are selected. After the coarse aggregate is coated with asphalt, soak in water and boil for 3 minutes, then take it out. Mass loss, which is used to characterize the asphalt exfoliation rate of asphalt-coated aggregates after water boiling.

[0043] The calculation process of the asphalt spalling rate of the asphalt-coated aggregate after boiling treatment is as follows:

[0044] 1) Take 5 washed and regular-shaped coarse aggregates (number 1 # ~5 # ) placed in an oven at 105°C±5°C for 1 hour, and then hung on an analytical balance with strings and weighed respectively, and the dry mass of 5 coarse aggregates was measured respectively, and weighed W 1 .

[0045] 2) Pour an appropriate amount of asphalt into a container, raise the temperature to 150°C, immerse the coarse aggregates that have been dried in step 1) and tied with thin threads into the asphalt, and keep the temperatur...

Embodiment 2

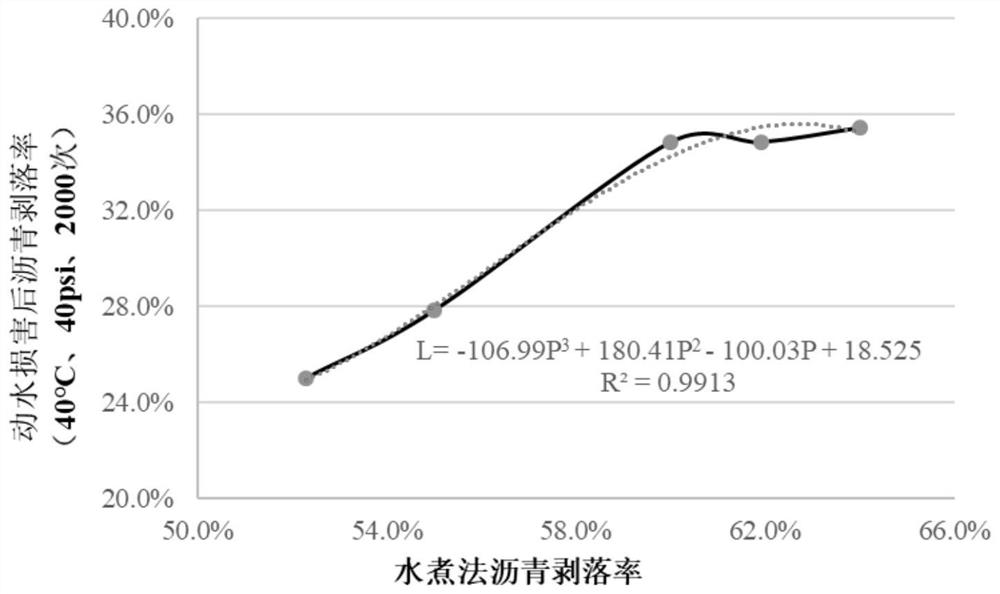

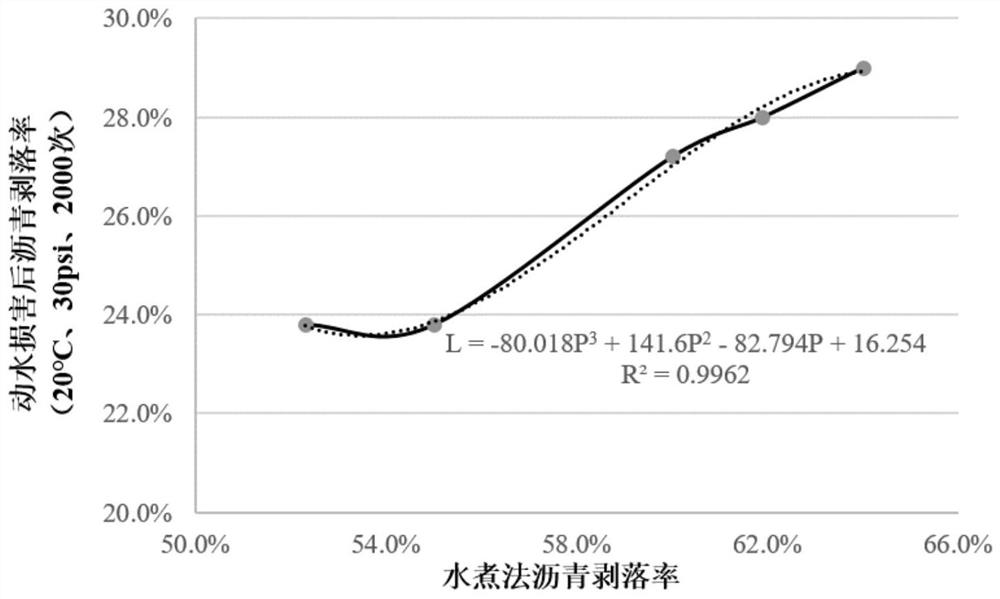

[0068] Change the parameter settings of the water damage sensitivity tester in the step (1) of Example 1, set the temperature to 20°C, the pressure value to 30psi, and the number of dynamic water cycle damages to be 2000 times, and the rest of the steps are consistent with those in Example 1 . Substitute the parameters into the formula y=(a×f+b×t+c×p) / η(f is the number of dynamic water damage, t is temperature, p is pressure, a=0.004, b=0.2, c=0.2 are respectively The service life factors of dynamic water damage times, temperature and pressure, η is the real simulation degree of dynamic water damage), the real simulation degree of dynamic water damage η=95% of the water damage sensitivity tester, the temperature is 20 ℃, the pressure value is 30psi, dynamic water damage cycles of 2000 times correspond to the actual damage period of asphalt concrete pavement is 18.9 years;

[0069] Refer to Table 1 in Example 1 for the bitumen spalling rate of the boiling method, and see Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com