A 3D modeling and measurement method for microscopic multiphase structure based on cross-section profile sequence

A multi-phase structure and three-dimensional modeling technology, which is applied in three-dimensional metallographic testing, mechanical manufacturing technology and image measurement fields, can solve problems such as high cost, low precision, and difficult reconstruction of three-dimensional models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

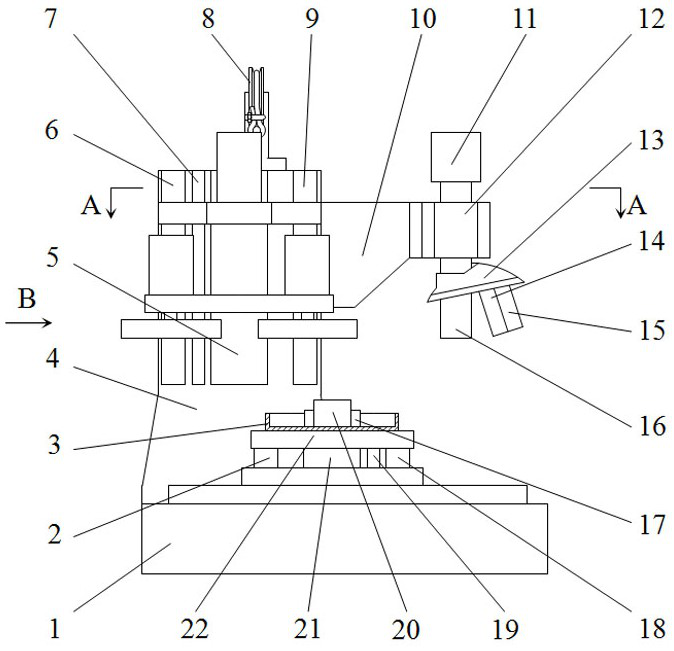

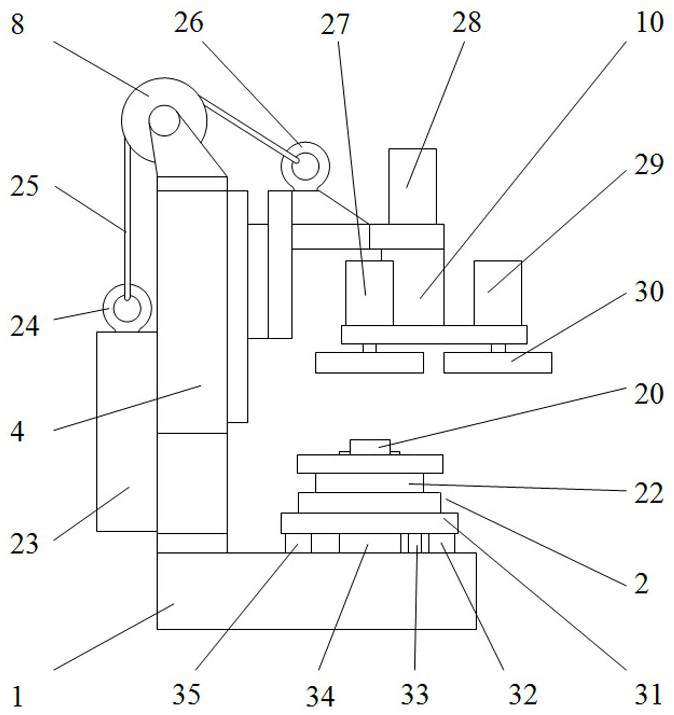

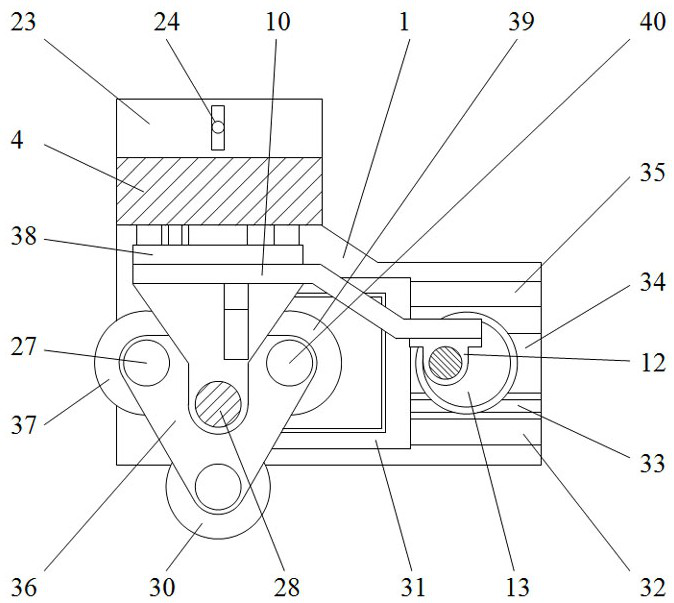

[0036] A three-dimensional modeling and measurement device for microscopic multiphase structure based on the sequence of cross-sectional profiles, mainly for samples of particle-reinforced composite materials, such as figure 1 As shown, it is mainly composed of high-precision CNC three-axis mobile platform, indexable precision plane grinding and polishing device, image acquisition device and accessories:

[0037] The high-precision CNC three-axis mobile platform includes: the frame body of the three-axis mobile platform is composed of a base and a column perpendicular to the base on one side of the base. There are a pair of X-guiding rails on the base parallel to the direction of the column, and the X-guiding rails are in front of the base. In the middle of the side and the rear side, there is an X-direction worktable on the X-direction rail that can move linearly on the X-direction rail. The X-direction rail and the X-direction worktable form a sliding pair, and the X-directio...

Embodiment 2

[0043] A method for modeling and measuring a three-dimensional model of a microscopic multiphase structure based on a sequence of cross-sectional profiles. The sample type is mainly a particle-reinforced composite material. The following steps are carried out:

[0044] (1) Make the particle-reinforced composite material sample into a metallographic test sample, then place the sample on the tray, and then clamp the sample with clamps;

[0045] (2) Start the grinding wheel indexing motor, X-direction linear reciprocating motor and Y-direction linear reciprocating motor, so that the first grinding wheel is located directly above the sample, move the beam downward, and use the first grinding wheel to perform trial grinding on the sample until the test The surface of the sample is completely ground by the grinding wheel;

[0046] (3) Keep the position of the beam unchanged, drive the X-direction linear reciprocating motor and the Y-direction linear reciprocating motor, so that the ...

Embodiment 3

[0057] The difference from the second embodiment is that the reconstruction of the high-precision three-dimensional metallographic model after grinding the polycrystalline metal material layer is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com