A blast furnace burden surface imaging three-dimensional model reconstruction method and system

A blast furnace charge surface and 3D model technology, applied in the field of metallurgy, can solve the problems of the blast furnace charge surface height and surface shape, which are difficult to accurately measure the blast furnace charge surface imaging 3D model, to improve cloth information feedback, reduce image details, and reduce noise the effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

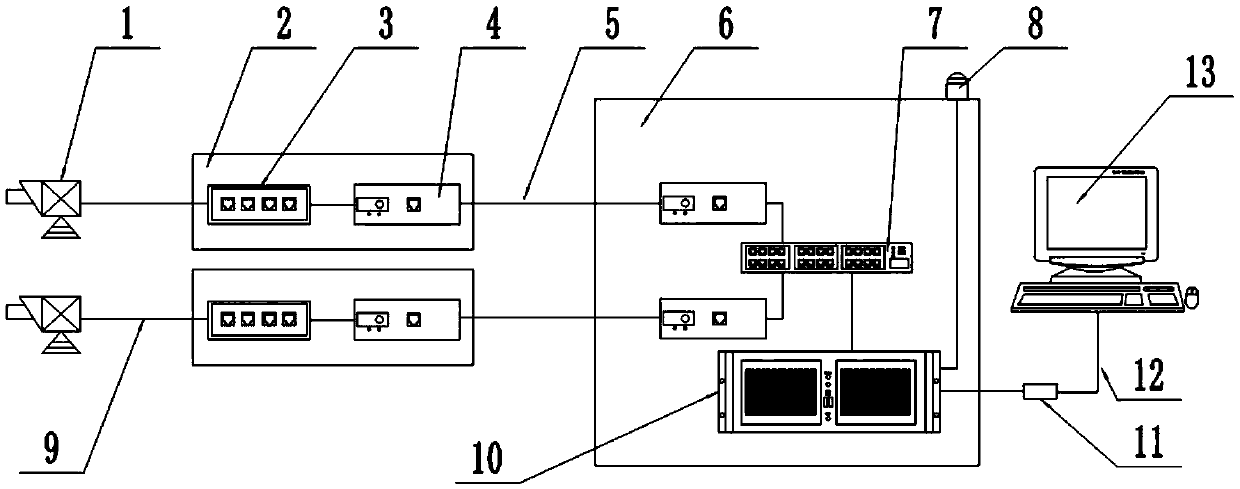

[0043] like figure 1 As shown, the three-dimensional model reconstruction system for blast furnace material level imaging includes two thermal imaging cameras 1 and an on-site control box 2 arranged on the site, as well as a control cabinet 6, an alarm 8 and a display 13 arranged in the control room;

[0044] Wherein, two thermal imaging cameras 1 are arranged on the horizontal direction and the vertical direction of the furnace wall of the blast furnace respectively, a pinhole lens is arranged at the front end of each thermal imaging camera 1, and a rotating device is connected at the rear end, and the rotating device is installed by The flange is fixed on the furnace wall of the blast furnace and forms a certain angle with the furnace wall of the blast furnace. Among them, the rotating device adopts the device in the published patent CN 201810478147. , so that the images in the furnace collected by the thermal imager completely cover the material surface in the furnace; each...

Embodiment 2

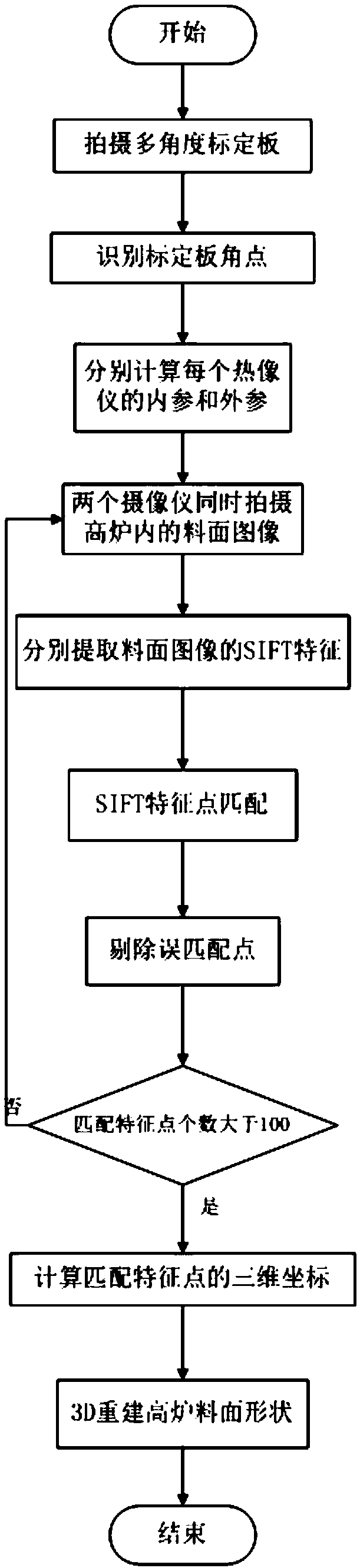

[0050] like figure 2 As shown, the specific implementation steps of the three-dimensional model reconstruction method for blast furnace charge level imaging realized by the above blast furnace charge level imaging three-dimensional model reconstruction system are as follows.

[0051] 1. Monitoring work preparation:

[0052] According to the structural layout of the real-time state monitoring system of the blast furnace charge level in Example 1, connect each system and debug the field control box and electrical cabinet to the normal working state, so that the power supply, electrical control, and data communication can work normally, and the pressure and temperature of the nitrogen cooling system Debug normal supply status;

[0053] Wherein, the outer air inlet provided on the rear side wall of the protective jacket and the inner air inlet provided on the side wall of the accommodating cavity are both connected to the cooling medium; specifically, the cooling medium adopts a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overlap degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com