Blast furnace charge level radar scanning 3D imaging device and monitoring system and monitoring method thereof

A blast furnace material surface and radar scanning technology, applied in the field of metallurgy, can solve problems such as inability to guarantee accuracy, incompatibility between temperature and material surface height, and difficulty in the distribution of material surface in the furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

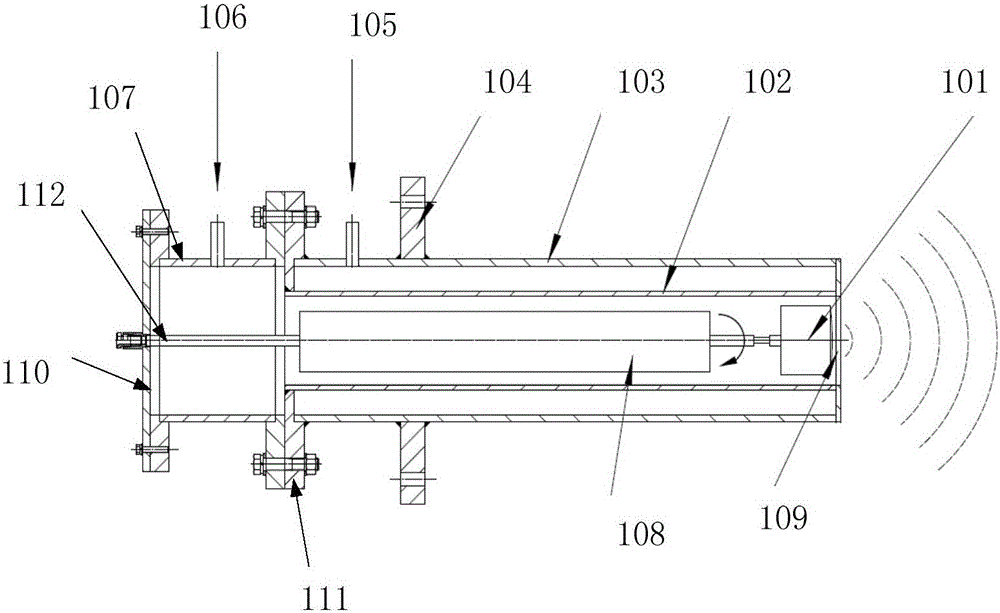

[0041] Such as figure 1 As shown, the 3D imaging device for blast furnace charge level radar scanning includes a microwave radar detector 101, a protective cover, an accommodating cavity 107, a rotating device 108 and a rear cover 110; wherein,

[0042] The protective cover includes a protective inner cover 102 and a protective outer cover 103. The protective outer cover 103 is arranged on the outside of the protective inner cover 102 in the form of a gap with the protective inner cover 102, and a ring end is arranged at the front end of the protective cover to be sealed and connected to the end face of the protective cover. Cover, a connecting flange 111 is arranged and fixed at the rear end of the protective jacket 103, and the flange cover of the connecting flange 111 is installed on the rear end face of the protective cover, so that the protective cover is formed into a closed annular structure with a center A sleeve body with through holes is formed; the microwave radar d...

Embodiment 2

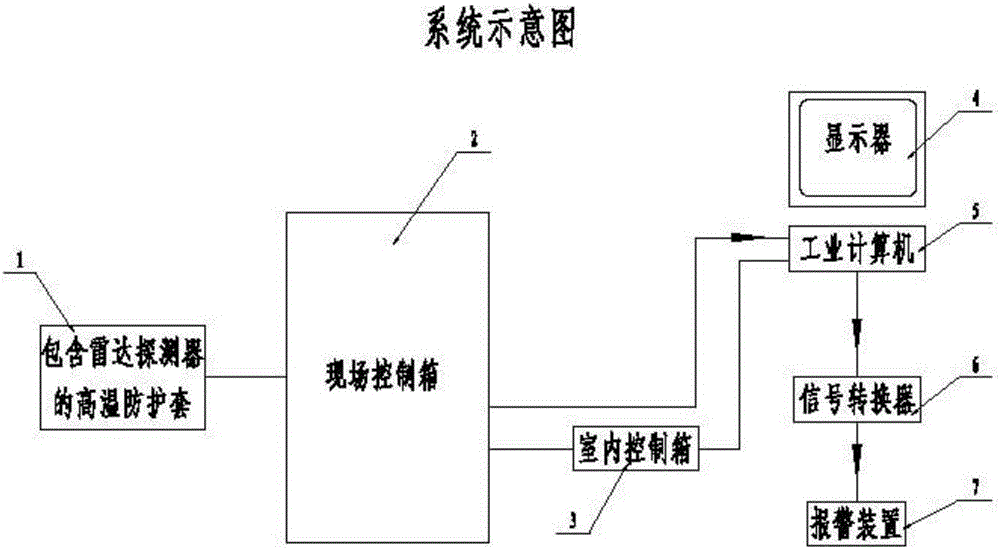

[0044] Such as image 3 As shown, a dynamic monitoring system for the shape of a blast furnace charge surface includes the blast furnace charge surface radar scanning 3D imaging device 1 described in Embodiment 1, a field control box 2, an indoor control box 3, a display 4, an industrial computer 5, and a signal converter 6 and alarm device 7; wherein:

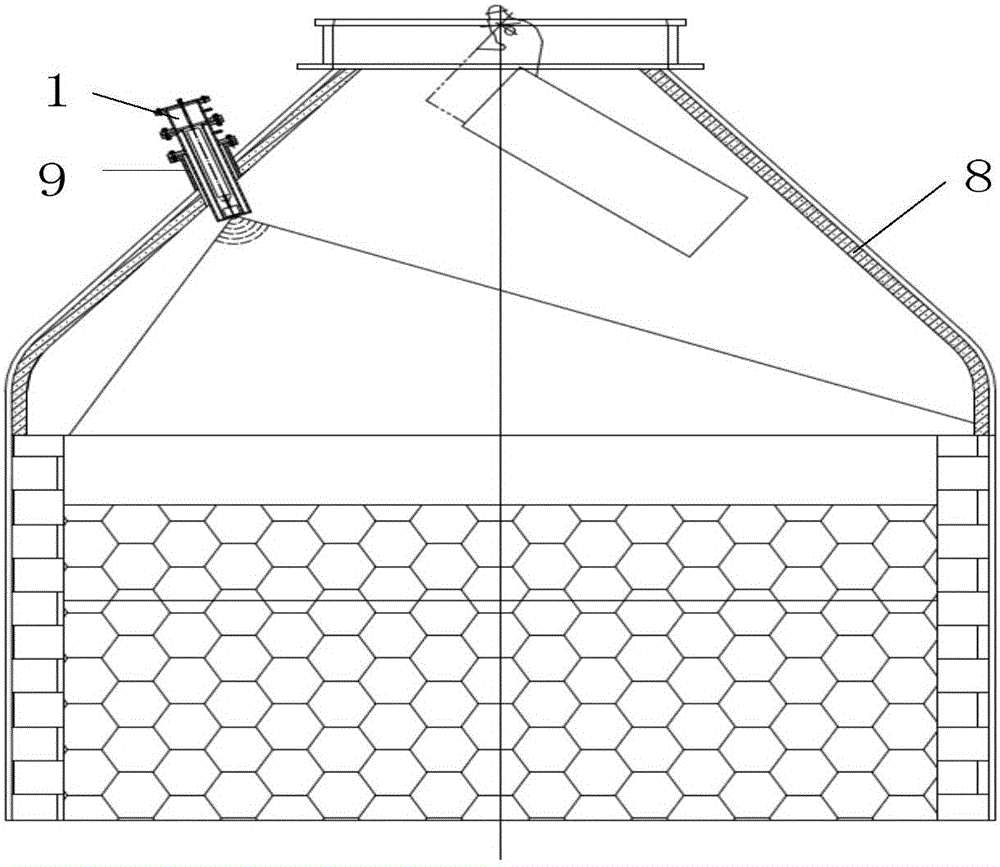

[0045] The blast furnace material level radar scanning 3D imaging device 1 is installed on the furnace wall above the blast furnace, such as figure 2 As shown, the installation angle between the imaging device 1 and the blast furnace wall is compatible with the internal structure of the blast furnace, ensuring that the scanning range of the microwave radar detector rotates 360° to cover the entire blast furnace material surface; Overlay scanning of all blast furnace material surfaces in the furnace;

[0046] The on-site control box 2 is set adjacent to the blast furnace, and the 3D imaging device 1 for radar scanning of the...

Embodiment 3

[0050] A method for real-time monitoring of the blast furnace charge level real-time state monitoring system using the blast furnace charge level shape dynamic monitoring system described in embodiment 2, comprising the following specific steps:

[0051] 1. Monitoring work preparation:

[0052] Connect each device according to the real-time state monitoring system structure of the blast furnace material surface, and debug the field control box and indoor control box to the normal working state, so that the power supply, electrical control, and data communication can work normally, and the pressure and temperature of the nitrogen cooling system can be adjusted to the normal supply state. ;

[0053] The outer layer air inlet 105 provided on the rear end side wall of the protective jacket 103 and the inner layer air inlet 106 provided on the side wall of the accommodating cavity 107 are both connected to the cooling medium; specifically, the cooling medium adopts a delivery press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com