Double-sided laminated double-glass high-reflective component

A laminated, double-sided technology, applied in the field of double-sided laminated double-glass high-reflective components, can solve problems such as current mismatch, achieve power optimization, increase component strength, and maximize component efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

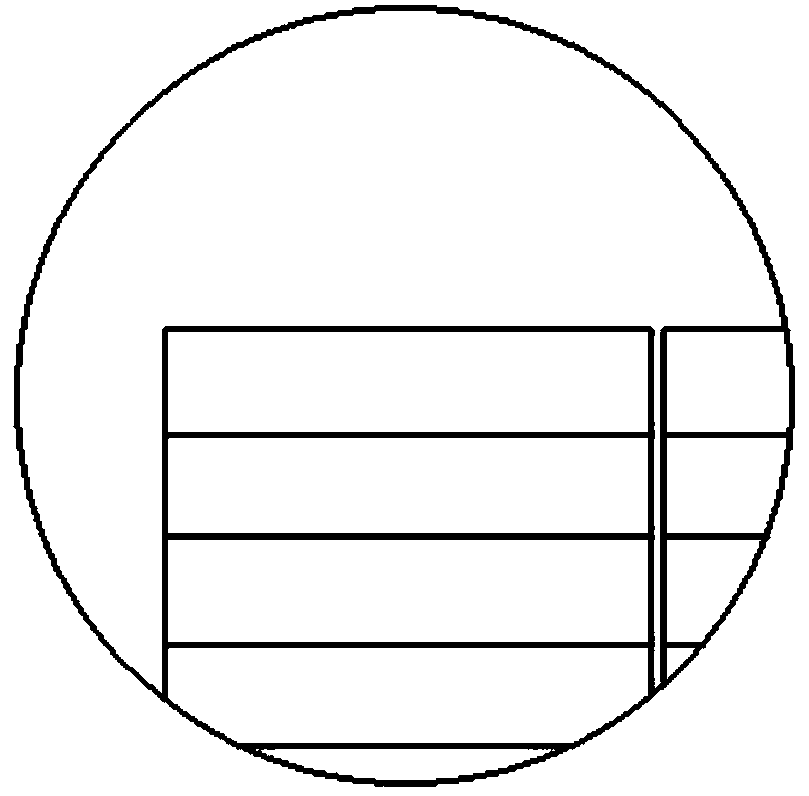

[0036] High-efficiency double-sided cells are used for 1 / 5 cutting; the stringing method is: 34 cells are connected in series, 5 strings are connected in parallel, and then 2 groups of 5 strings are connected in series; the packaging material is POE; the final cover On the back glass with a special grid design, the back grid design evenly covers the back of the battery sheet, and the high reflective layer covers the back of the battery sheet. The side of the battery string covers a width of 3mm, and the battery string head covers a width of 2mm for lamination.

[0037] Specific lamination parameters:

[0038]

[0039] Component power:

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com