A connector cam assembly mechanism

A cam assembly and connector technology, which is applied in the assembly/disassembly of contact parts, contact parts manufacturing and other directions, can solve the problems of low processing production efficiency, difficulty in ensuring consistency and high quality of processed products, and high labor intensity of workers, and achieves high processing efficiency. High efficiency, eliminating manual assembly work, and good production and processing consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

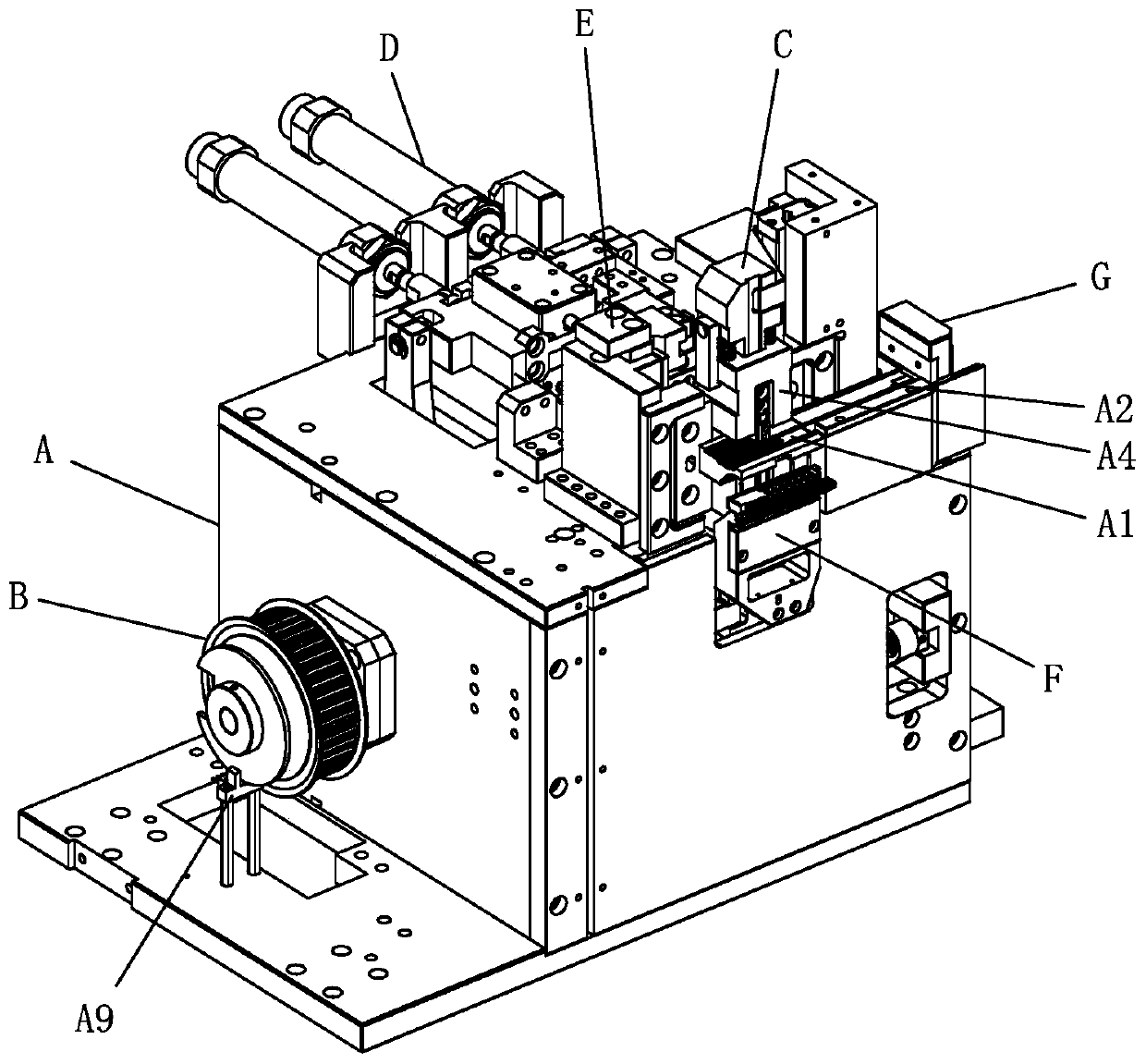

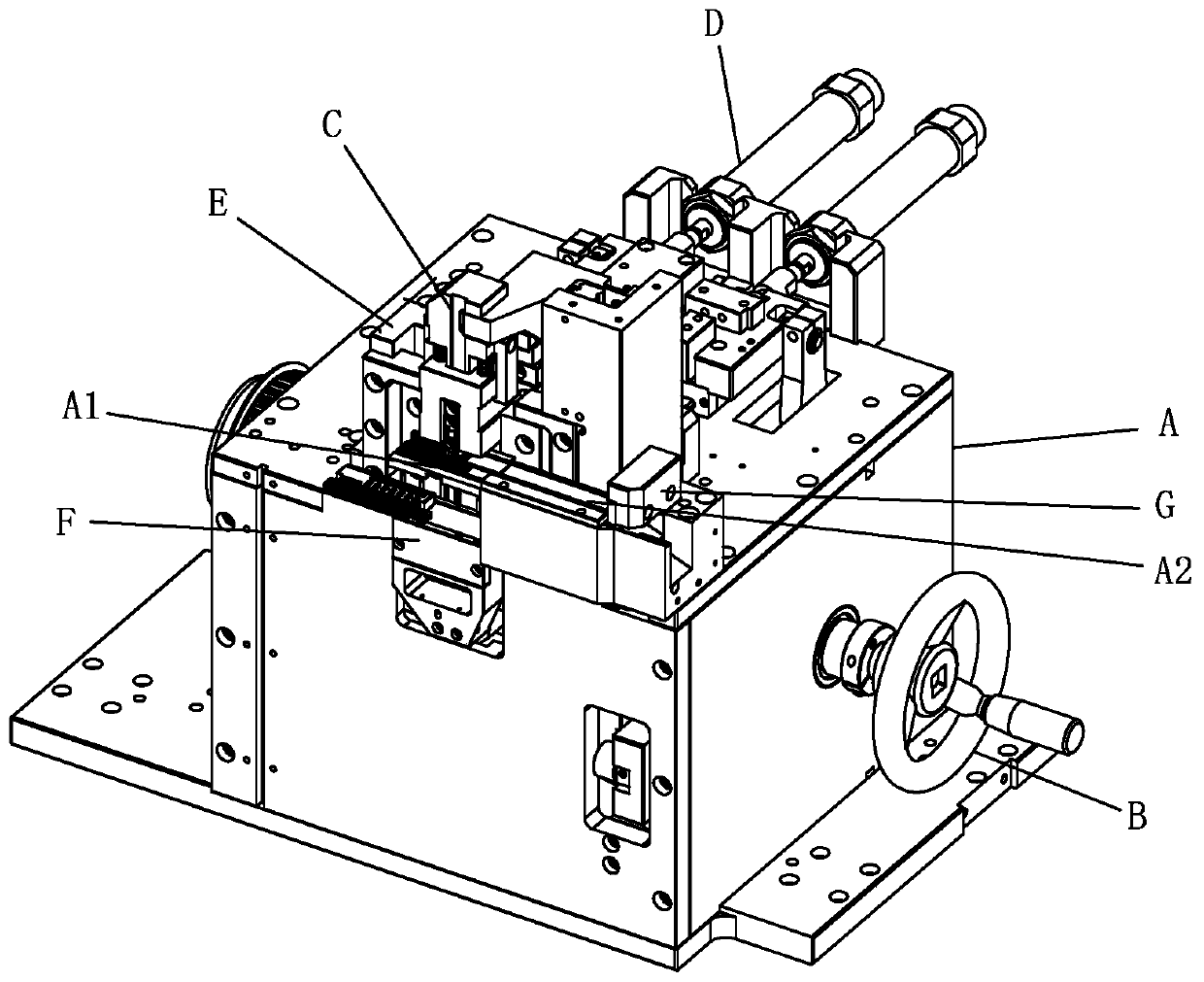

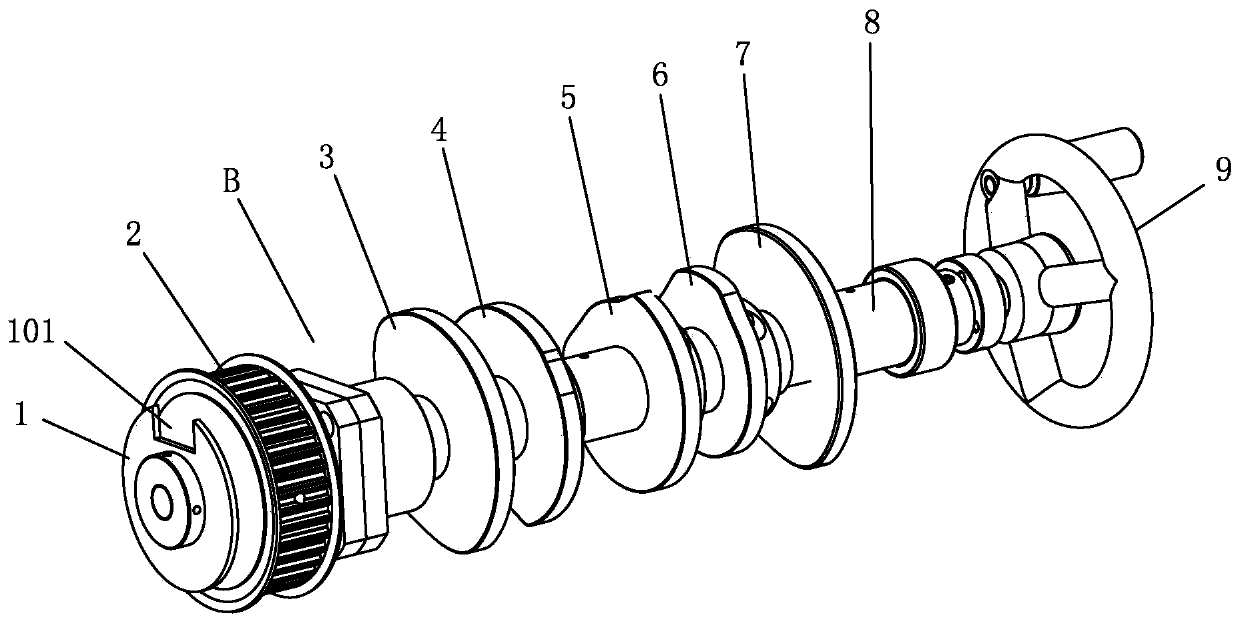

[0034] see Figure 1-Figure 19 , the connector cam assembly mechanism includes a cutting mechanism C for cutting the terminal material strip H (the terminal material strip H is composed of a carrier material strip 61 and a terminal piece 62), and a material cutting mechanism C for pushing the terminal piece 62 The assembled pushing mechanism D; the cutting mechanism C and the pushing mechanism D are driven by the power output mechanism B respectively; On the fourth cam 6, the power source drives the fourth cam 6 to rotate through the transmission main shaft 8. The cutting mechanism C includes a cutting swing rod 11 and a cutting punch 17, one end of the cutting swing rod 11 is hinged on the frame through the first hinge seat A3, and the other end of the cutting swing rod 11 and the cutting punch 17 A material cutting transmission assembly is provided;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com