A flexible crimping device and method suitable for microwave components

A technology of microwave components and crimping devices, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of increasing the difficulty of assembling printed boards of microwave components and affecting the reliability of microwave component assembly, so as to improve the ability of rapid delivery and have the advantages of Reusability and the effect of reducing the void rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

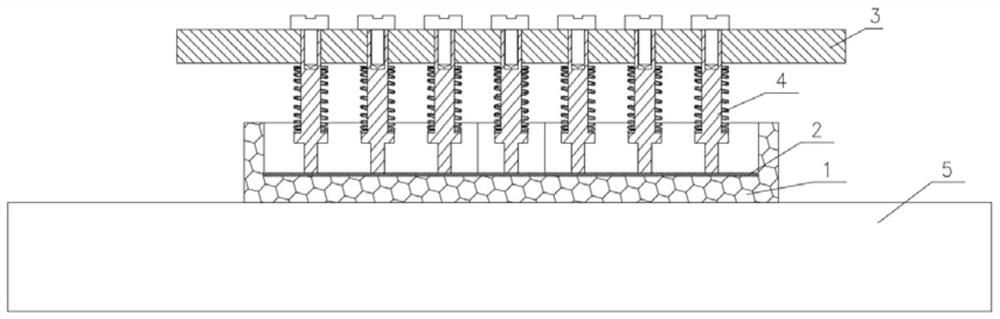

[0040] A flexible crimping method suitable for microwave components, comprising the following steps:

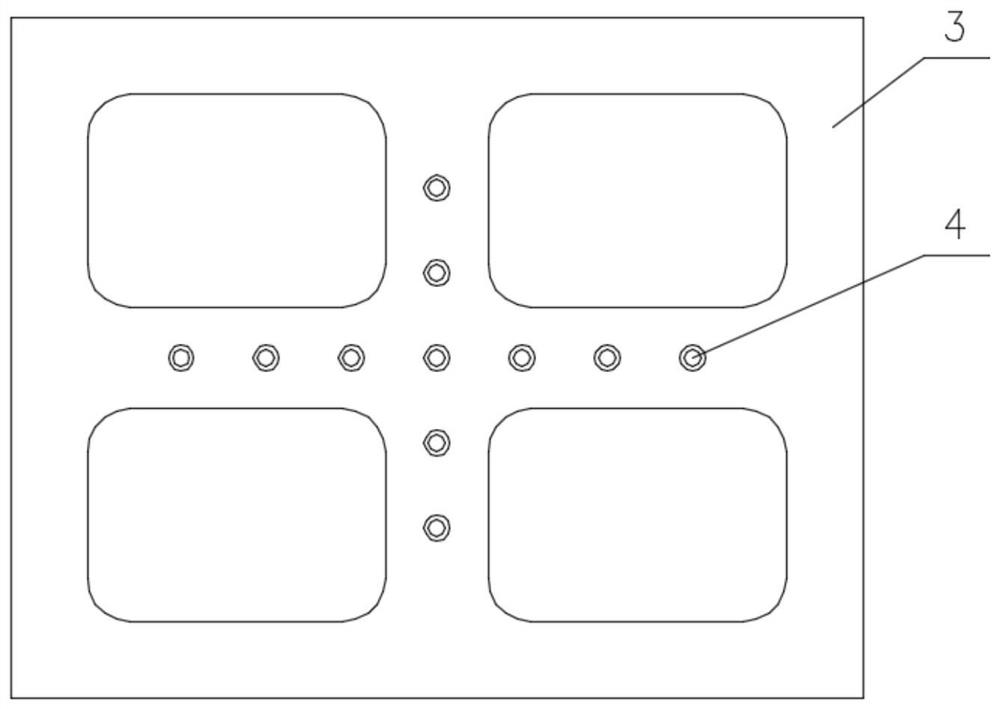

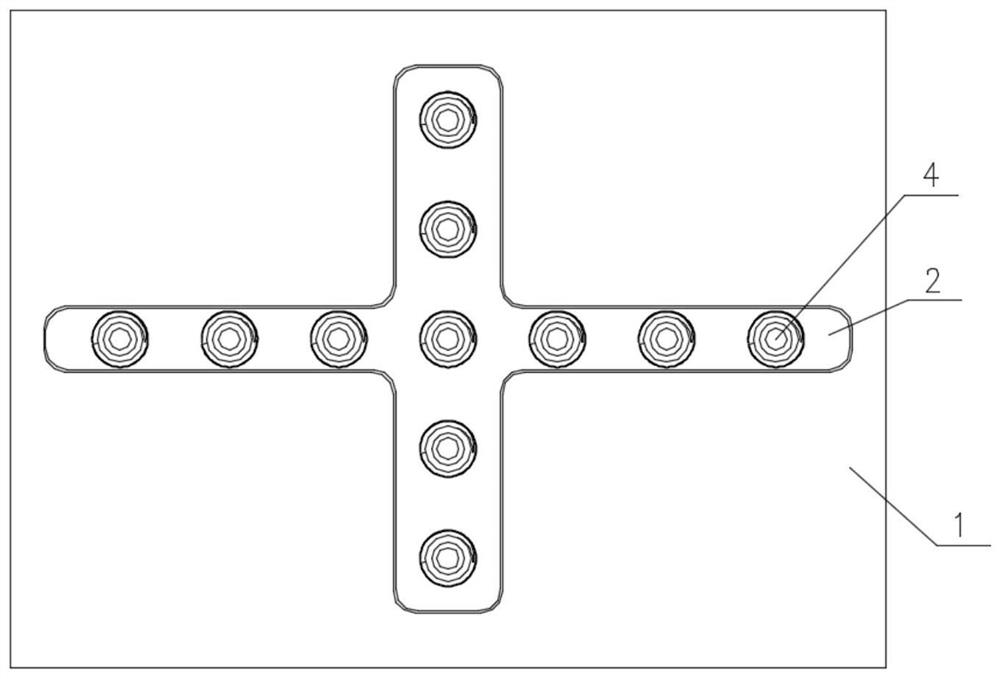

[0041] (1) The microwave component structure 1 is fixed to ensure that the microwave component structure 1 will not slide relative to the heating table 5; the surface of the microwave component structure 1 that needs to be welded with the printed board 2 is evenly coated with solder or put in Corresponding to the profiling solder sheet of the printed board 2; put the printed board 2 into the microwave component structure 1 to ensure the correctness of the placement position of the printed board 2; fix a support plate 3 at a certain height on the microwave component structure 1;

[0042] (2) Open a light hole of a certain size on the support plate 3 and the position where pressure needs to be applied on the printed board 2;

[0043] (3) Assembling a certain number of flexible units 4 capable of providing flexible force;

[0044] (4) Assemble a corresponding number of flexible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com