High-efficiency animal husbandry grass pulverizing device

A crushing device and animal husbandry technology, which is applied in the field of breeding, can solve the problems of inconvenient use, difficult movement of the device, and high labor intensity, and achieve the effects of reduced manufacturing costs, convenient movement, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

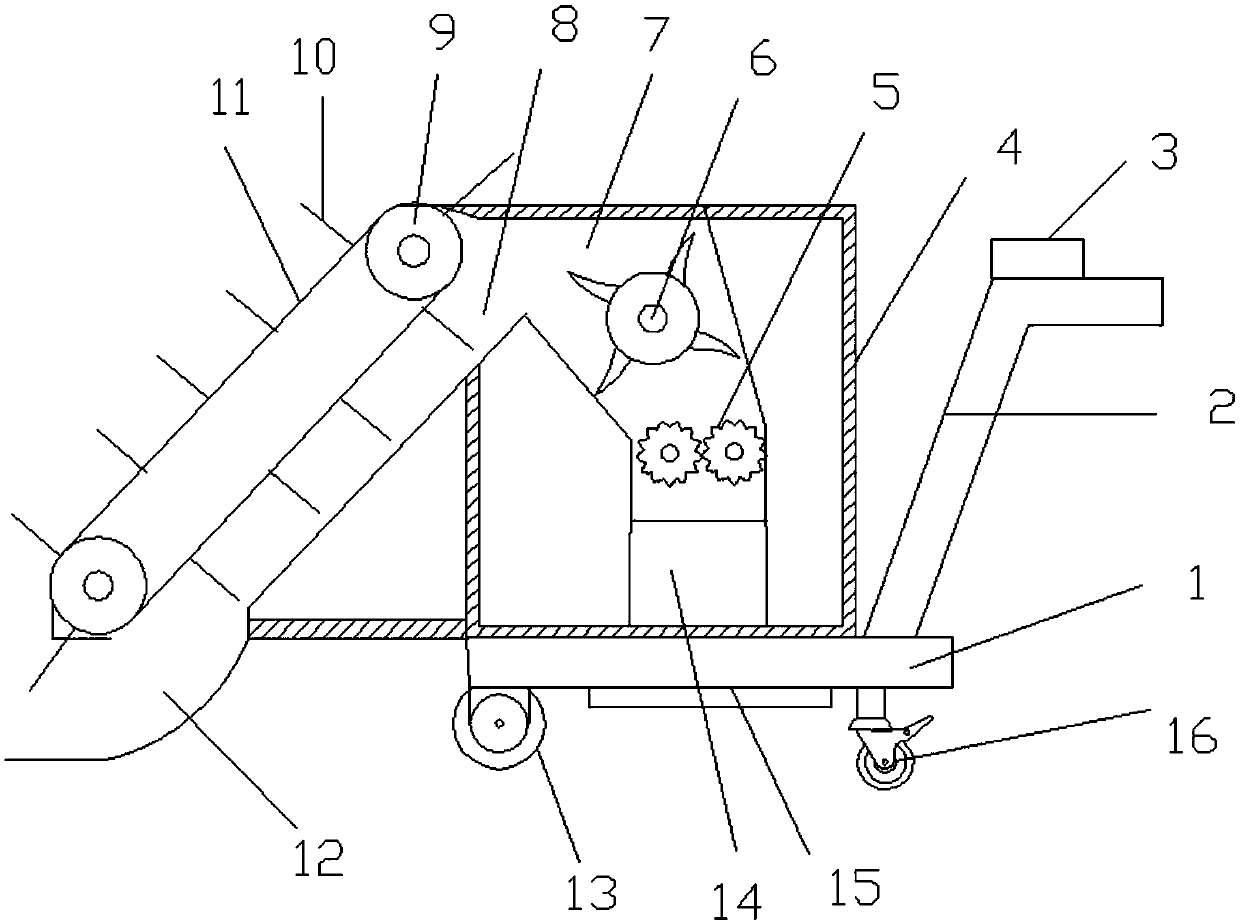

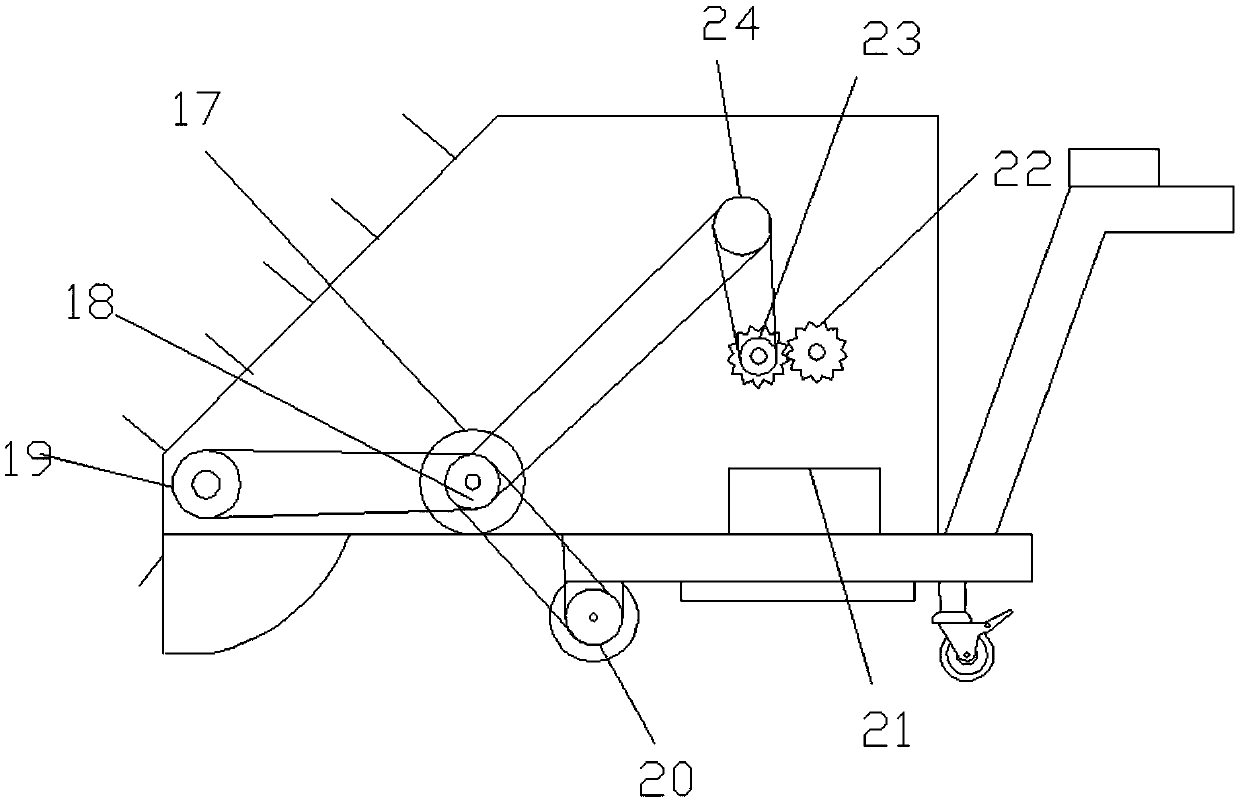

[0022] see Figure 1-2 , a high-efficiency animal husbandry grass crushing device, including a base 1, a housing 4 and a transmission channel 8. Both ends of the lower surface of the base 1 are provided with driving wheels 13 and universal wheels 16. The universal wheels 16 are provided to facilitate the steering and fixing of the base 1, making the device move more convenient. A second driven disk 20 is vertically fixed on the central axis of the driving wheel 13 , and the second driven disk 20 rotates coaxially with the driving wheel 13 . A storage battery 15 is installed in the middle of the lower surface of the base 1, and the storage battery 15 provides power for the device. The upper surface of the base 1 is provided with a housing 4, the proximal side of the housing 4 is fixedly mounted with a motor 17, the output shaft of the motor 17 is vertically connected with a drive disc 18, driven by the motor 17, the drive disc 18 and The output shaft of the motor 17 rotates c...

Embodiment 2

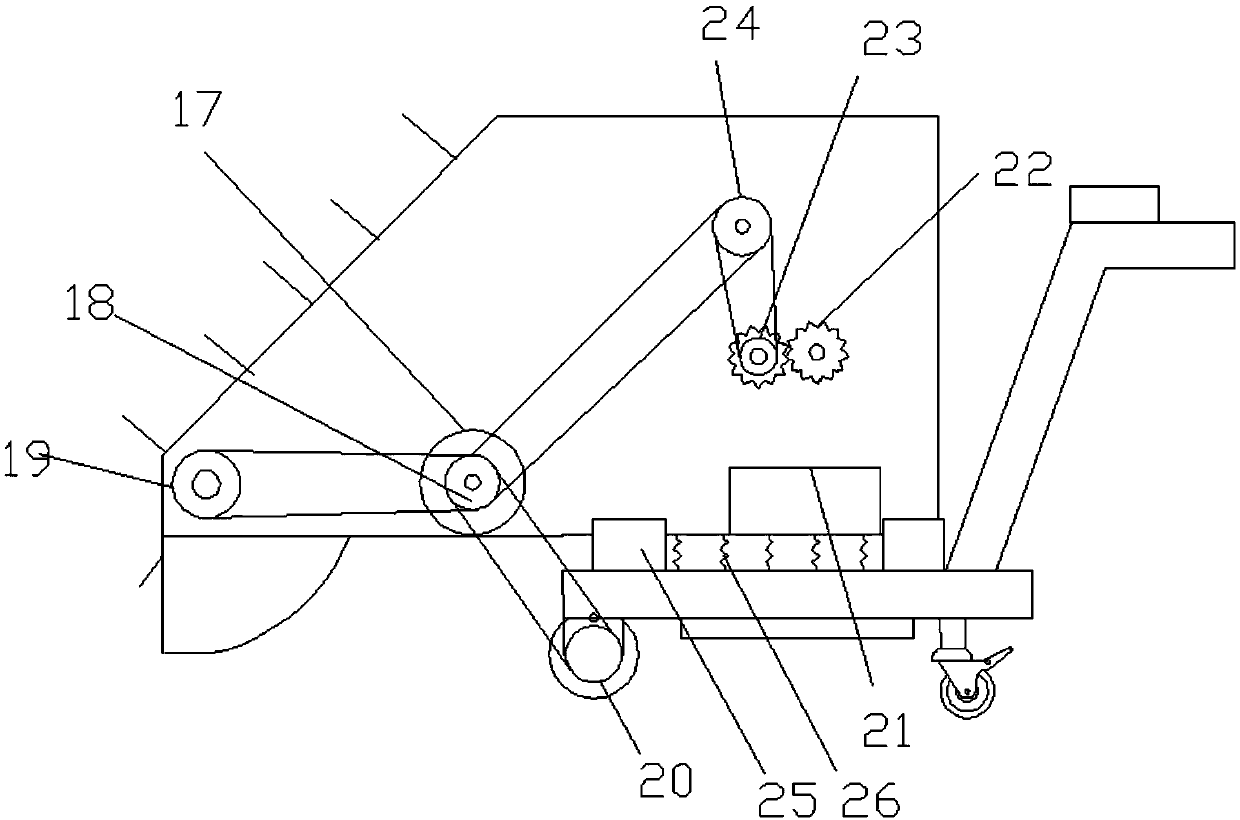

[0027] see image 3, on the basis of Embodiment 1, the bottom of the housing 4 is fixedly connected to the top of the spring 26, the bottom of the spring 26 is connected to the upper surface of the base 1, and the spring 26 has a shock-absorbing and supporting effect on the housing 4, The damage to the device caused by vibration is reduced, and the service life of the device is improved. The upper surface of the base 1 around the housing 4 is fixed with a number of limiting blocks 25, and the limiting blocks 25 block the housing 4 from around to prevent the housing 4 from shaking horizontally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com