Casting technology rapid verification method based on sand core 3D printing technology

A 3D printing and casting technology, applied in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of long cycle, differences in thermophysical parameters, difficult on-site collection, etc., to improve work efficiency, improve accuracy, and compare The effect of reducing mold repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

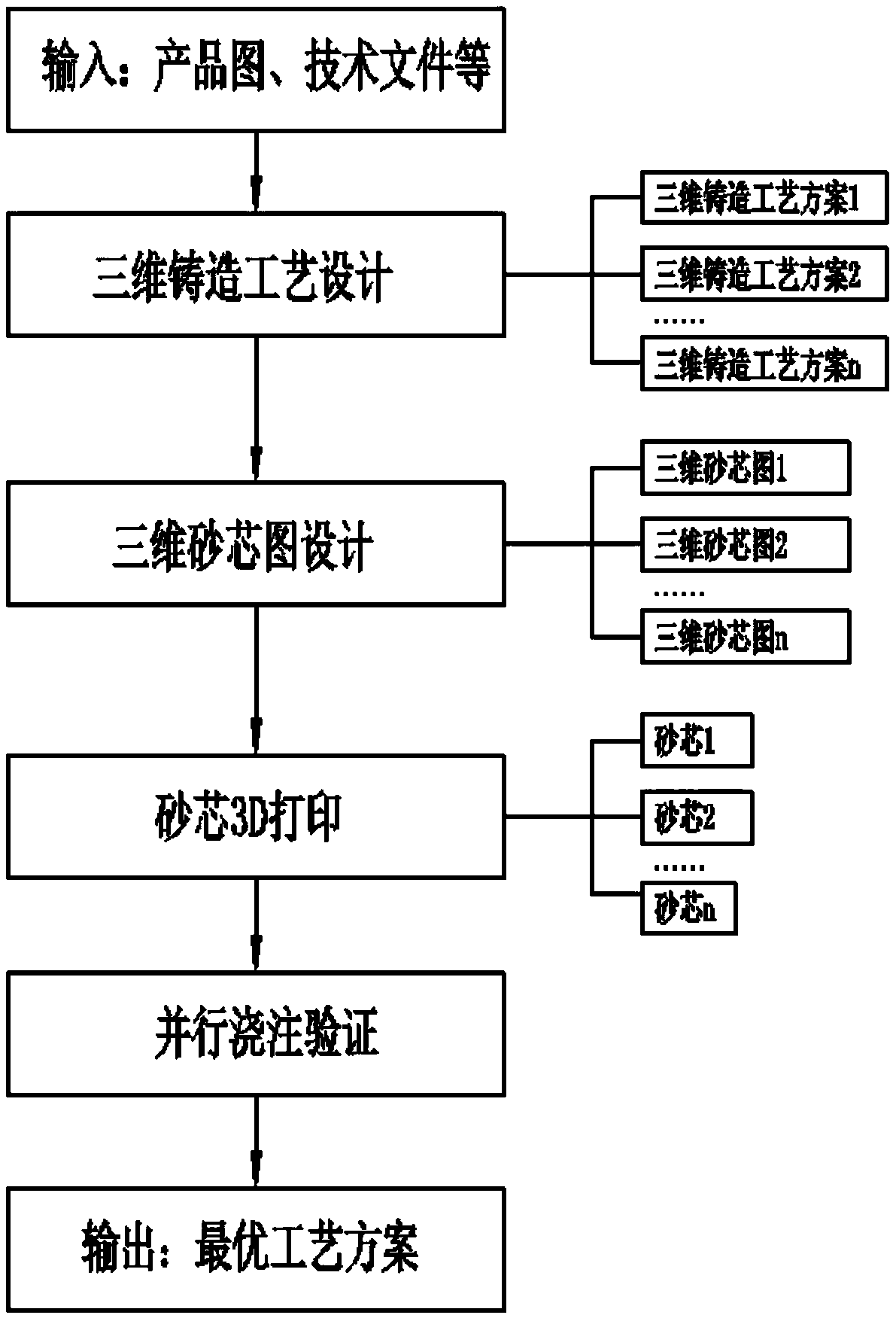

[0019] Attached below figure 1 Embodiments of the present invention are described.

[0020] A rapid verification method for casting process based on sand core 3D printing technology, such as figure 1 shown, including the following steps;

[0021] Step 1: Design of 3D casting process diagram: The design of 3D casting process diagram is different from the traditional planar 2D casting process design. In this invention, the input required for 3D printing of sand core is the 3D digital model of sand core, so it is necessary to carry out 3D casting process and sand core design. Therefore, in the stage of casting research and development or process improvement, it is first necessary to design and form a three-dimensional casting drawing according to the process parameters of the product part drawing, and then design and form a variety of three-dimensional casting process drawings according to the obtained three-dimensional casting drawing. Specifically, the three-dimensional cast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com