Photo frame chamfering machine

A technology of chamfering machine and photo frame, which is applied in the direction of metal processing machine parts, clamping, support, etc. It can solve the problems of low surface roughness of chamfering, inaccurate clamping and positioning, and poor efficiency of chamfering in mass production. The roughness of the processed surface is low, the clamping is fast and accurate, and the effect of unevenness is avoided

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

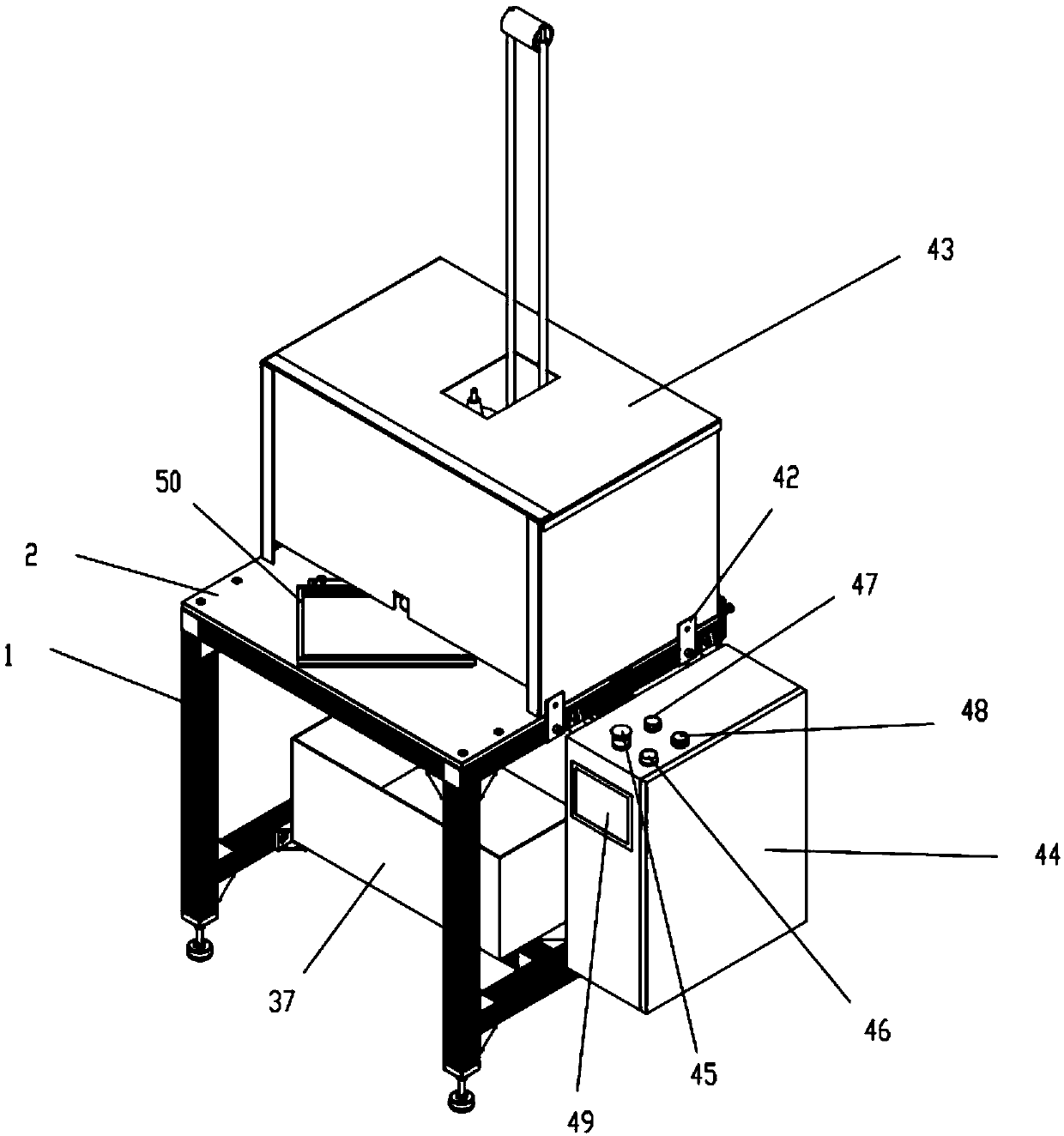

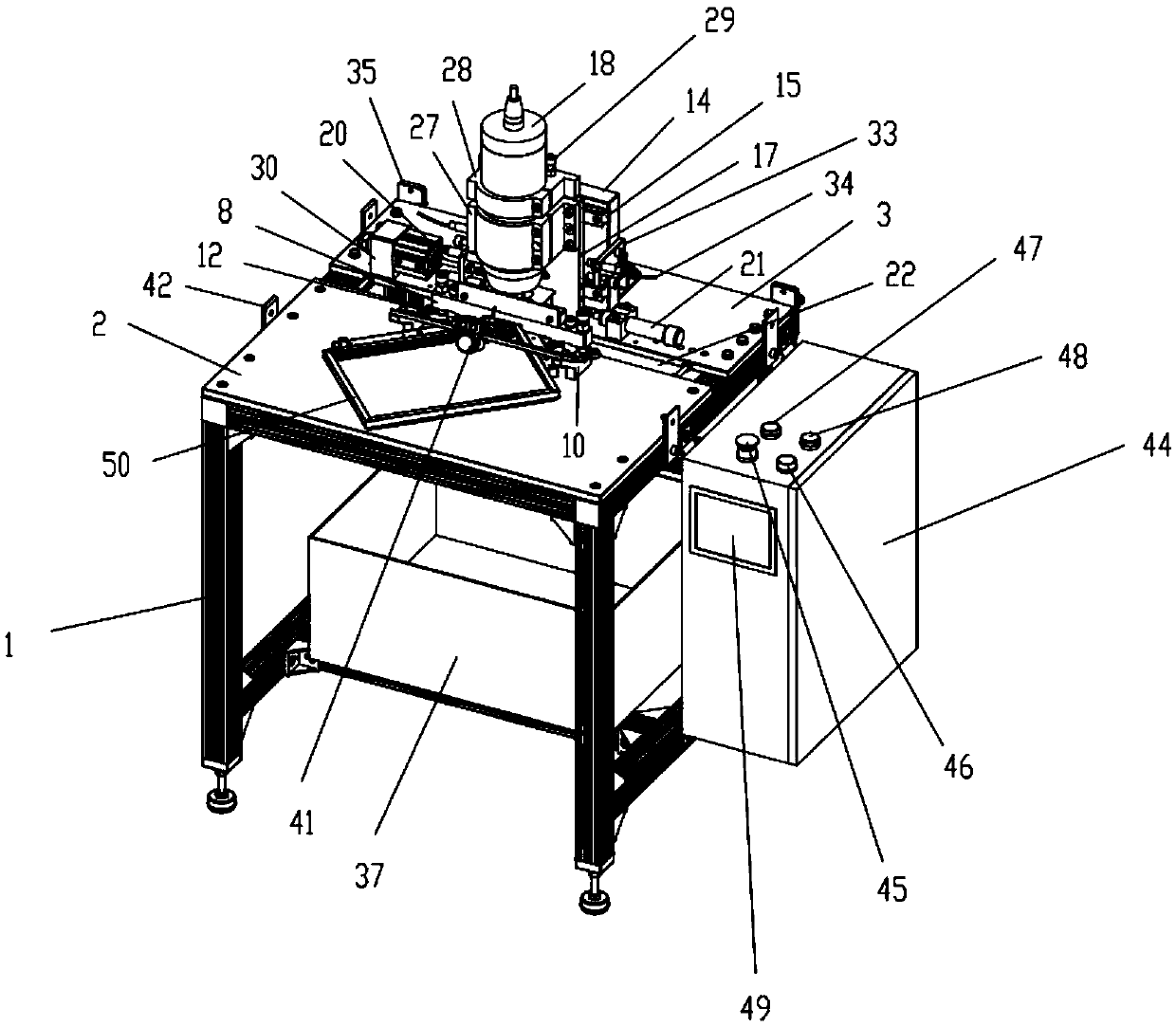

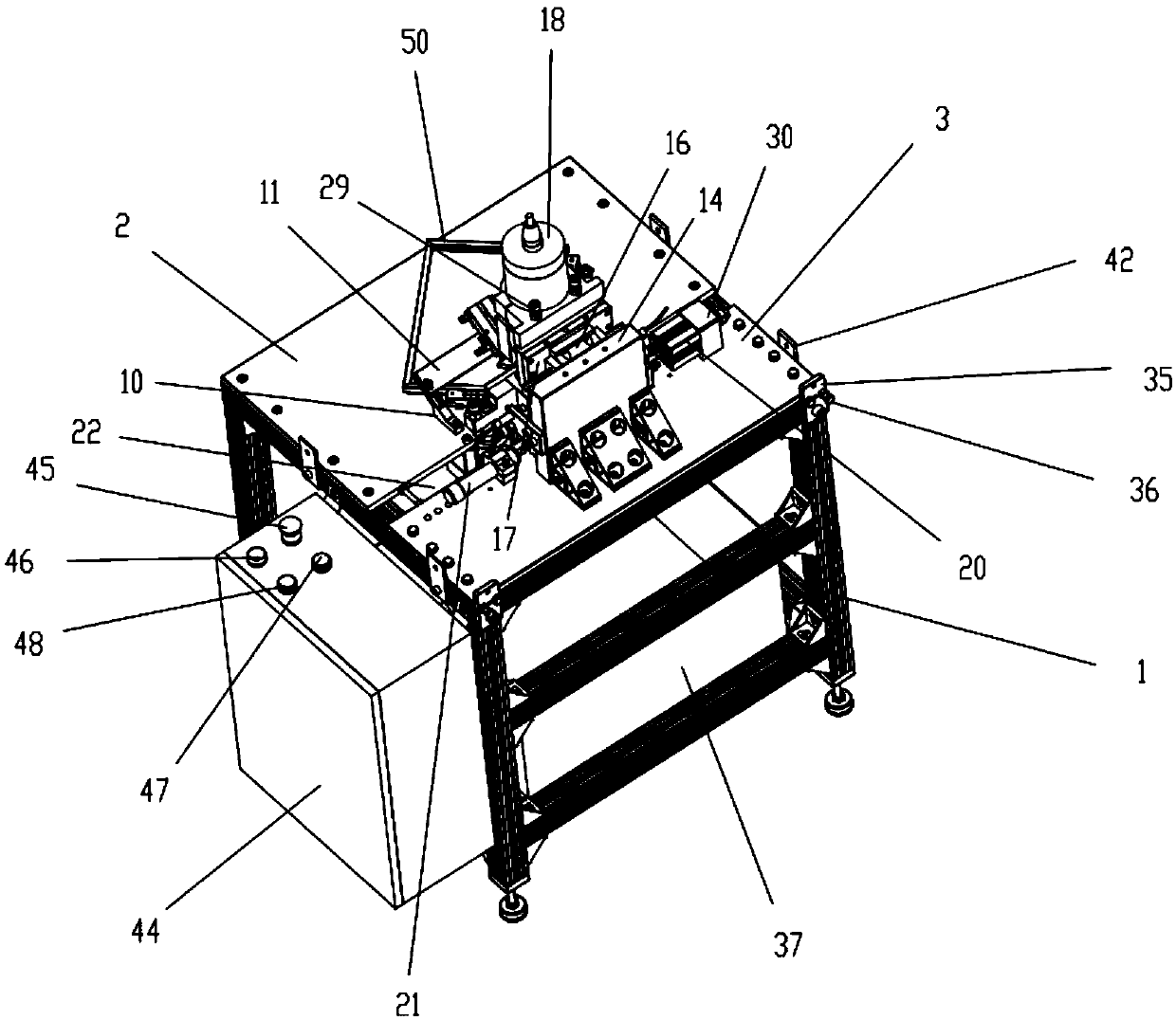

[0027] A kind of picture frame chamfering machine described in this embodiment 1, as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9As shown, it includes a rack 1, a front panel 2 and a rear panel 3 arranged on the top platform of the rack, a left positioning bar 4 and a right positioning bar 5 arranged on the front panel at an angle greater than 90 degrees, and a left positioning bar Three magnetic induction type proximity switches 6 and two air nozzles 7 are provided on the inner side of the right positioning bar and the pressing plate 8 is located on the front panel and is positioned at the top of the left positioning bar and the right positioning bar. The pressing plate is connected with two pressing plate cylinders 9 that control the pressing down or resetting of the pressing plate, the oblique pressure cylinder fixing block 10 that is arranged on the front panel and located in front of the pressing plate, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com