Longitudinal beam transmission structure of cargo compartment floor

A floor and stringer technology, which is applied to aircraft floors, aircraft accessories, etc., can solve the problems of increasing the weight of structural reinforcement, increasing the complexity and impact of the lower structure of the fuselage, and achieving simple reinforcement structure, light weight, and good manufacturability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

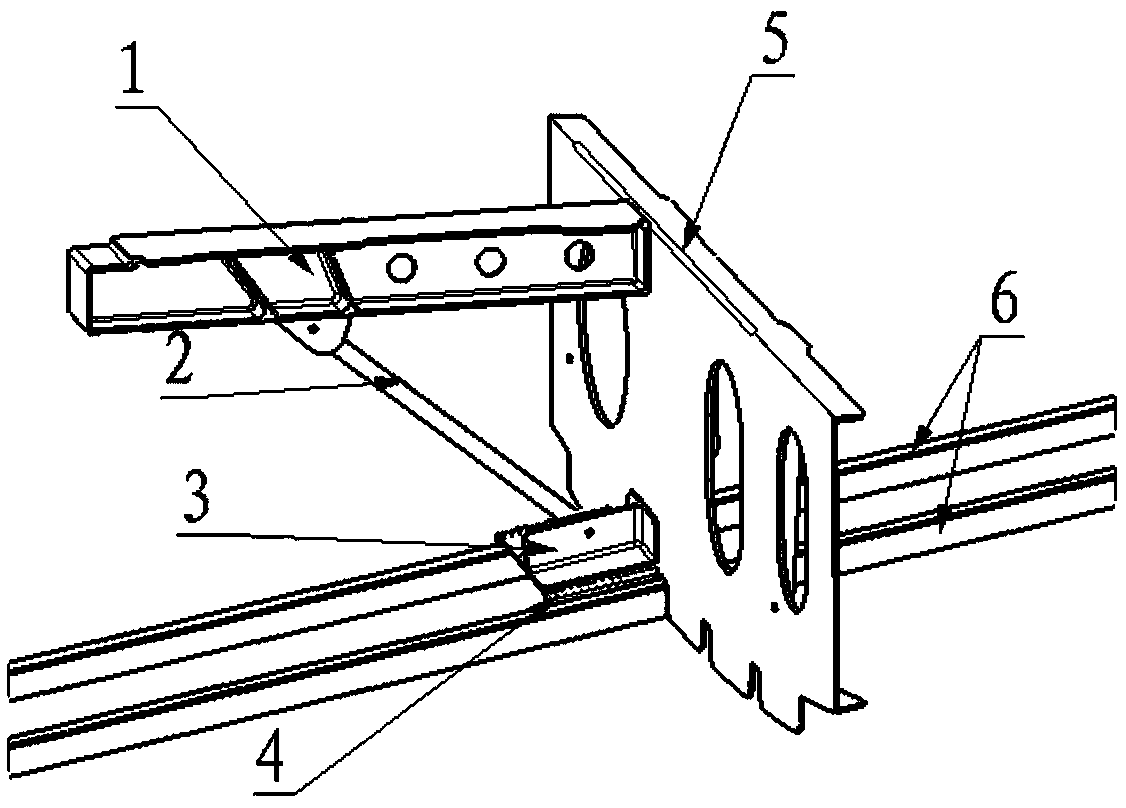

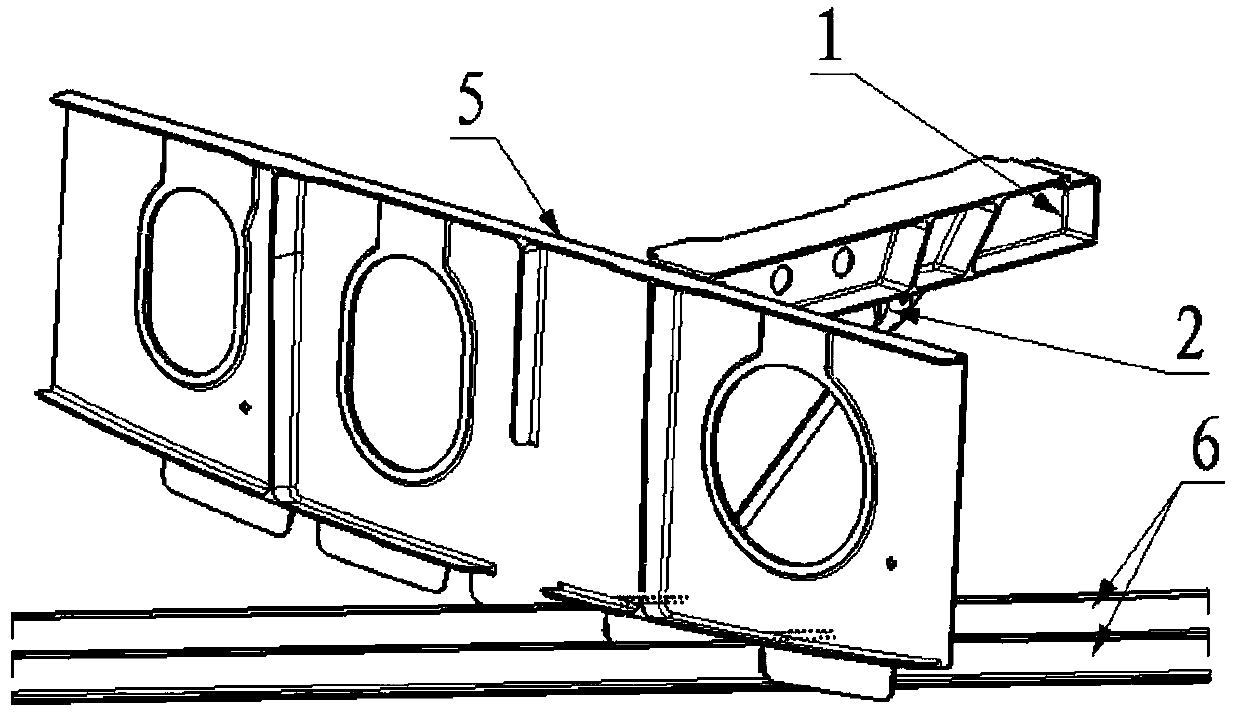

[0016] The reinforced structure of the cargo floor longitudinal beam forms a stable triangular structure through the cargo floor longitudinal beam [1], diagonal stay rod [2], connecting joint [3], diffuser [4], frame [5], and long stringer [6].

[0017] The two ends of the diagonal stay rod [2] are hinged with the floor stringer [1] and the connecting joint [3] through a single bolt, and only bear axial load; the connecting joint [3] and the diffuser [5] of the frame [4] are fixed , and the diffuser [5] is fixedly connected with the stringer [6]. Ribs are arranged on the back of the frame [4] for the transmission of vertical loads. The longitudinal load of the cargo floor longitudinal beam [1] is transmitted to the connection joint [3] through the diagonal stay rod [2], and then to the diffuser [4], and is finally borne by the long stringer [6], while the diagonal stay rod [2] shaft The component force of the axial load in the vertical direction is borne by the stiffeners on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com