Pigment sheet with various anti-counterfeiting functions and preparation method thereof

A technology of pigments and functions, applied in the field of pigment flakes with multiple anti-counterfeiting functions and its preparation, can solve the problems of less anti-counterfeiting pigments and single anti-counterfeiting function of anti-counterfeiting pigments, so as to improve the anti-counterfeiting performance, increase the difficulty of imitation, and increase the difficulty of imitation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

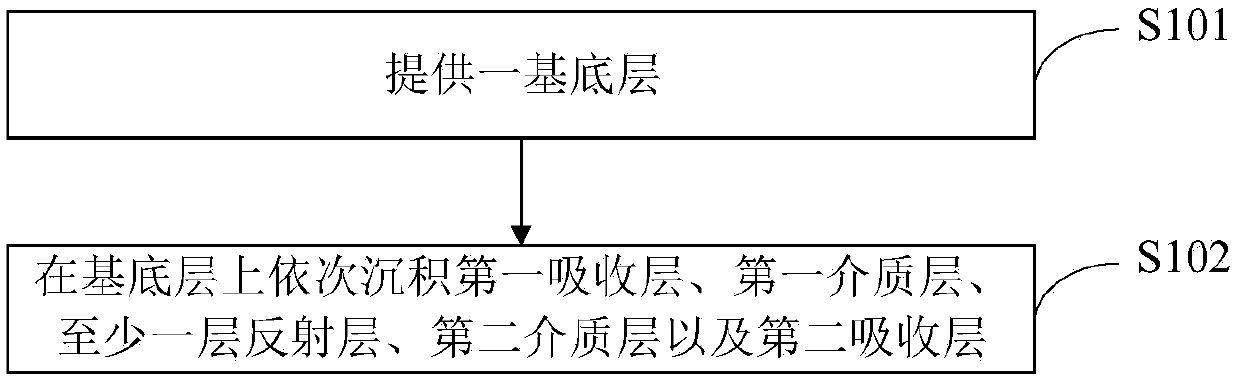

[0056] refer to image 3 , the preparation method of the pigment flakes with multiple anti-counterfeiting functions comprises the following steps:

[0057] S101: Provide a base layer.

[0058] Specifically, the base layer is a rigid base, for example, the material of the base layer is quartz glass.

[0059] S102: sequentially depositing a first absorption layer, a first dielectric layer, at least one reflective layer, a second dielectric layer, and a second absorption layer on the base layer.

[0060] Wherein, at least one of the reflective layer, the first medium layer, the second medium layer, the first absorbing layer or the second absorbing layer is a material layer containing a predetermined proportion of the magnetic resonance anti-counterfeiting material with electromagnetic wave response function.

[0061] Specifically, under high vacuum conditions, physical vapor deposition (PVD) can be used to sequentially deposit the first absorbing layer, the first dielectric layer...

Embodiment 1

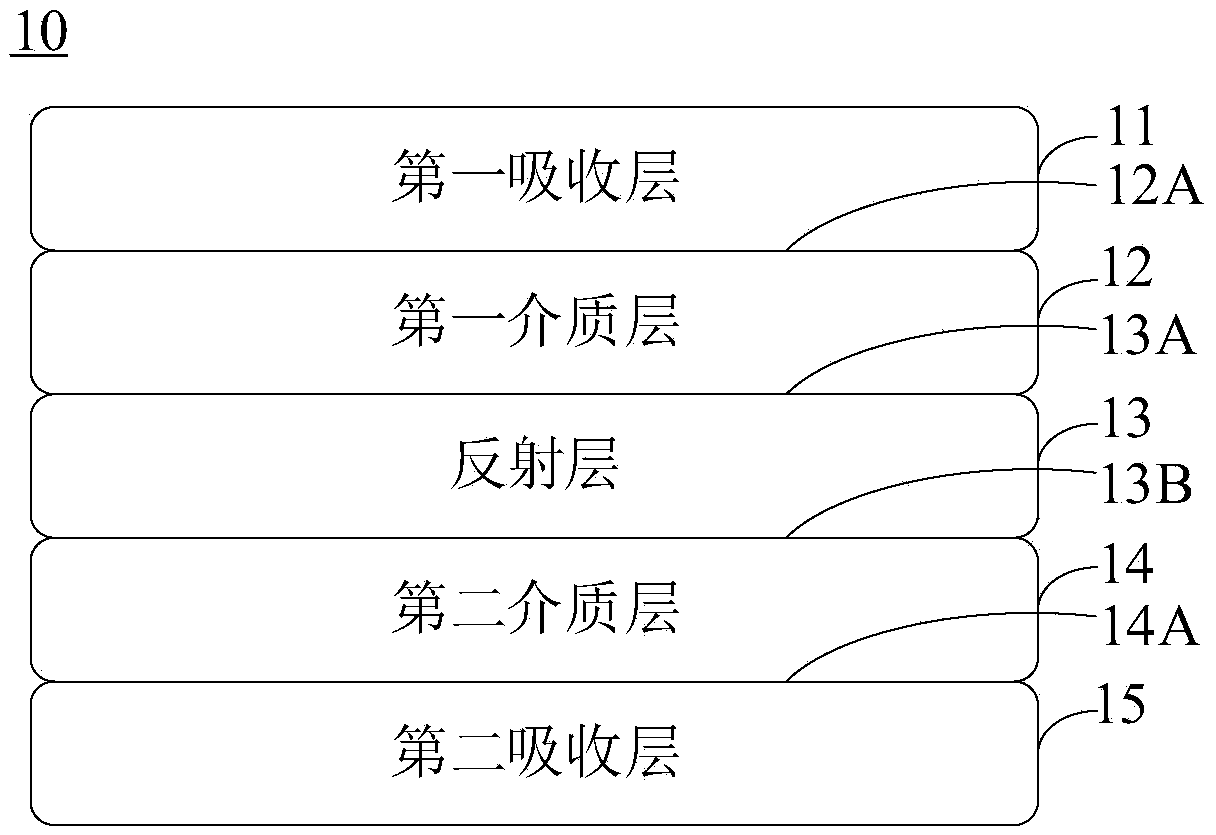

[0069] The pigment sheet includes a first absorption layer, a first medium layer, a first reflection layer, a second medium layer and a second absorption layer which are stacked.

[0070] In terms of mass percentage, 90-96% of the magnetic resonance anti-counterfeiting material is added to the first reflection layer, wherein the first reflection layer is an aluminum plate, and 95% of the magnetic resonance anti-counterfeiting material is added to the aluminum.

Embodiment 2

[0072] The pigment sheet comprises a first absorption layer, a first medium layer, a first reflection layer, a second reflection layer, a second medium layer and a second absorption layer which are stacked.

[0073] In terms of mass percentage, 90-96% of the magnetic resonance anti-counterfeiting material is added to the second reflection layer, wherein the first reflection layer is an aluminum plate, and 95% of the magnetic resonance anti-counterfeiting material is added to the aluminum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com