Template sewing machine

A sewing machine and template technology, which is applied to sewing machine components, sewing machine control devices, sewing equipment, etc., can solve problems such as poor stitch quality, design position deviation, and difficulty in maintaining consistent vibration amplitude, so as to improve sewing quality and precision Positioning, the effect of ensuring positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

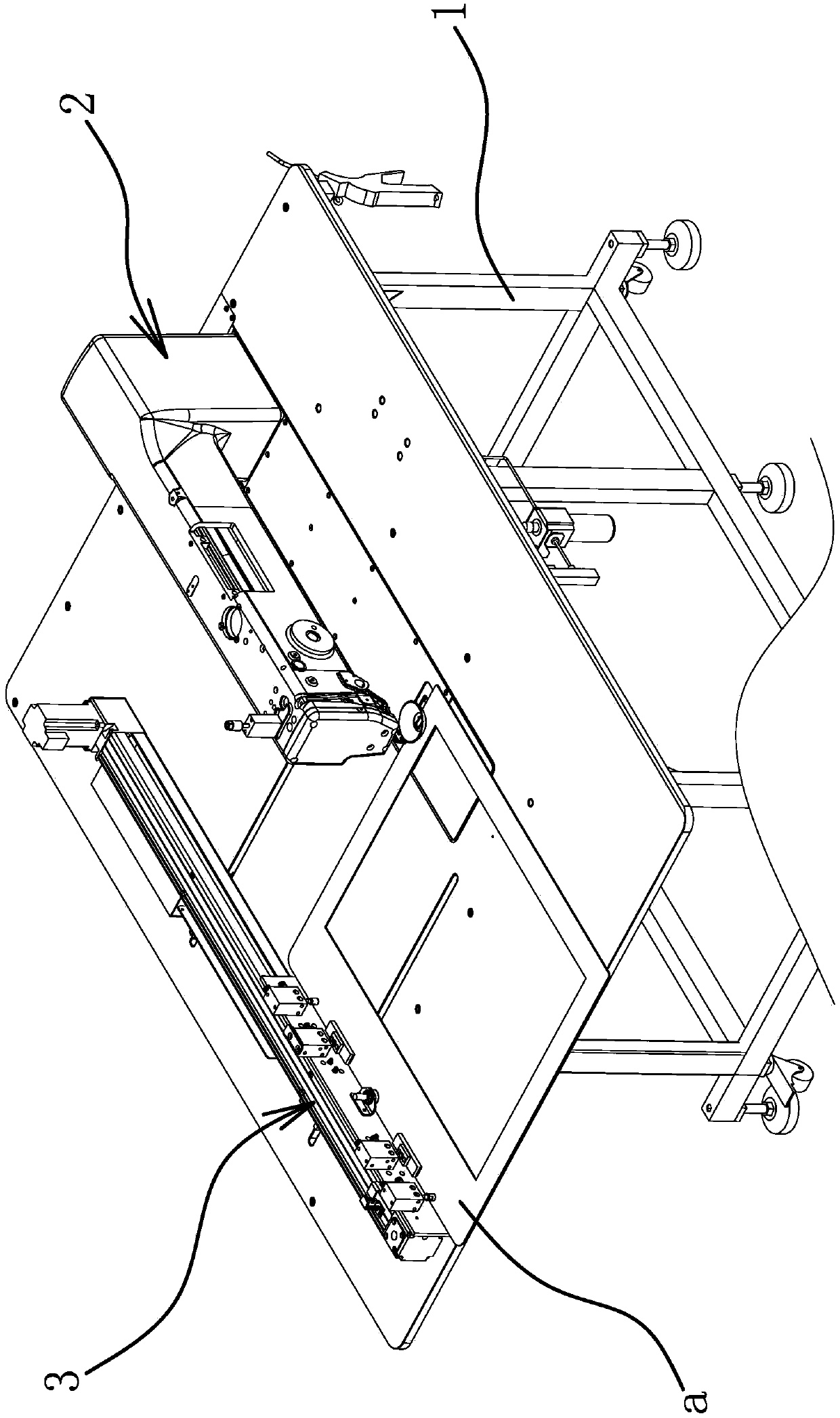

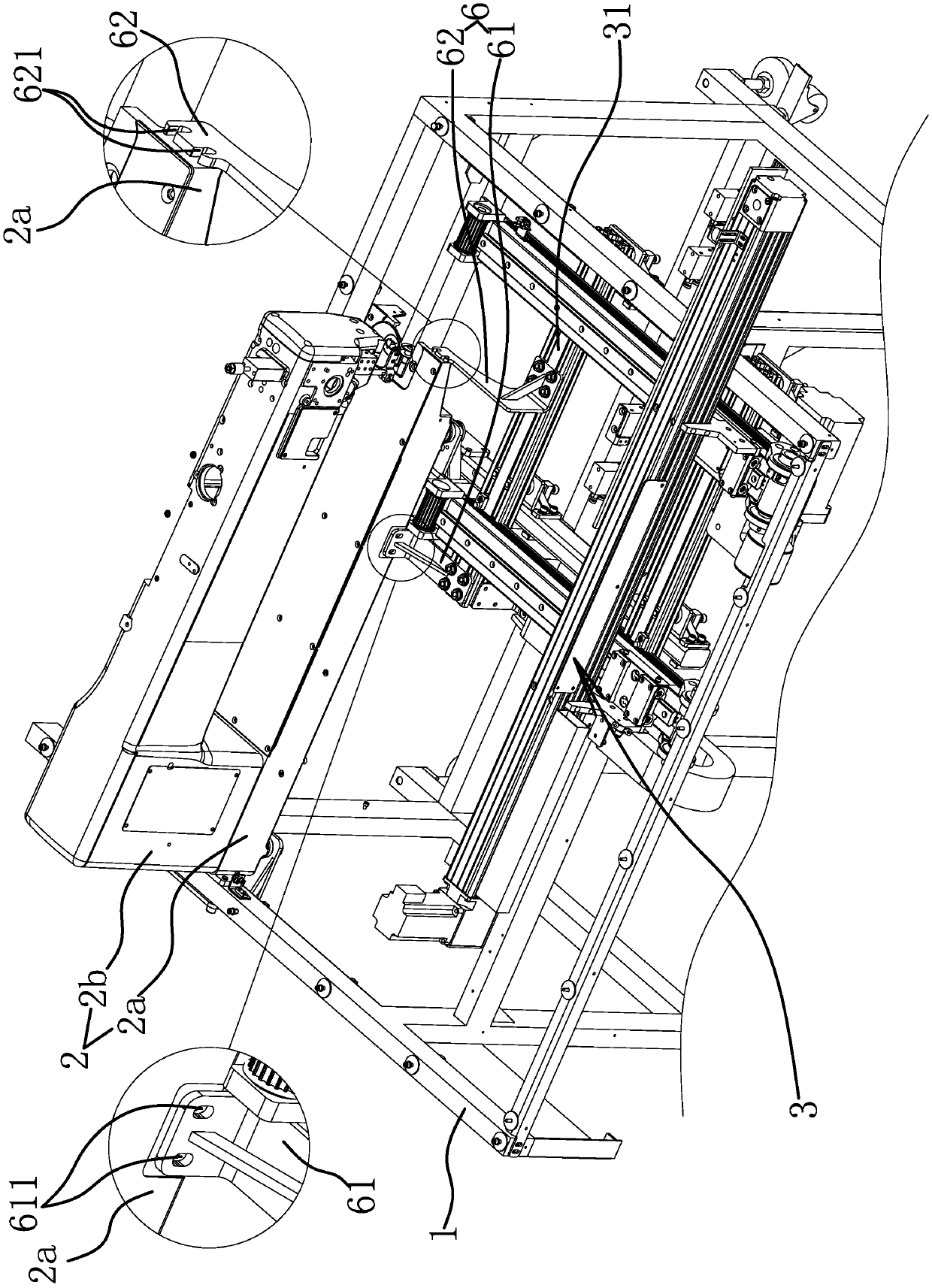

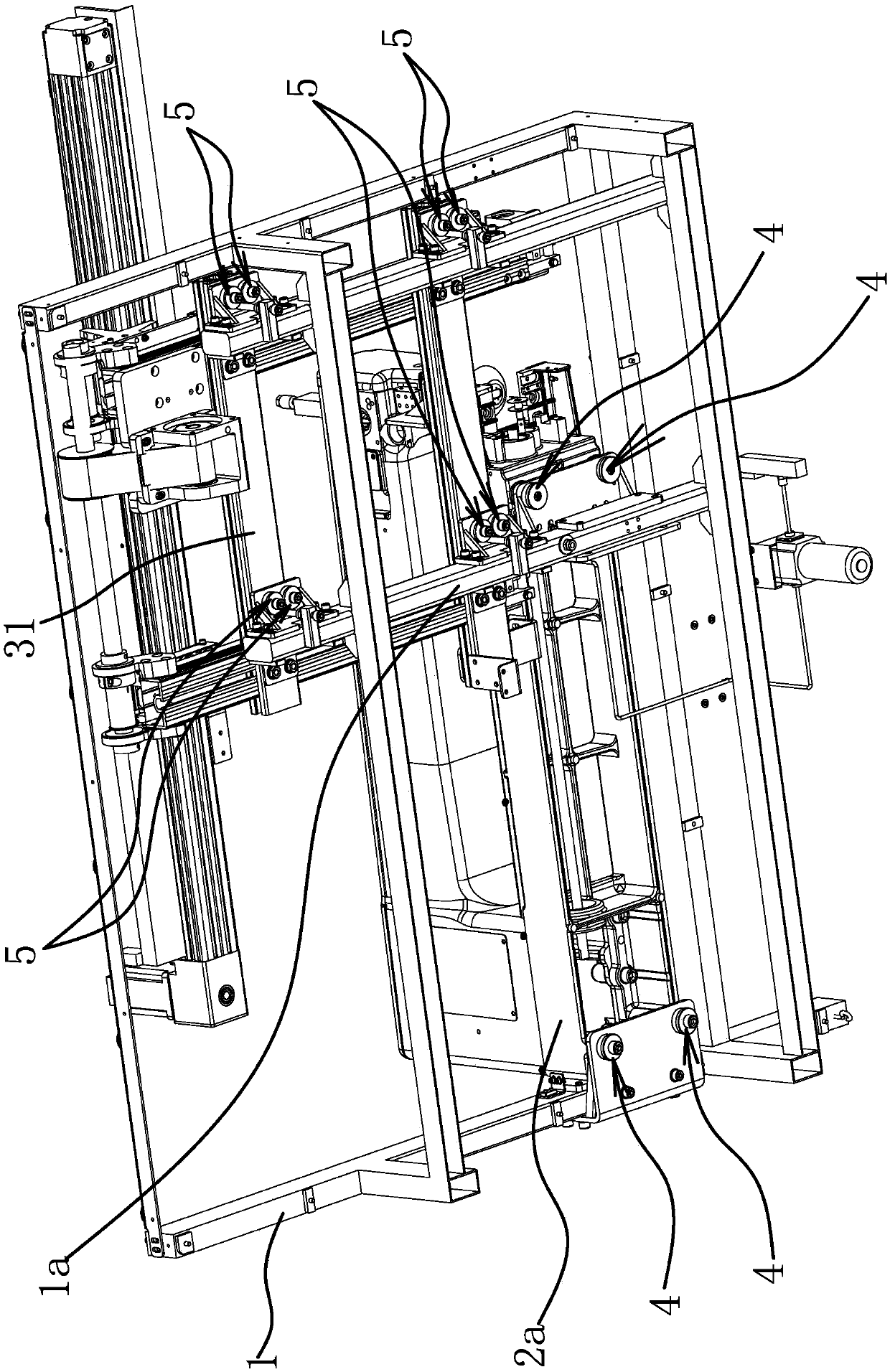

[0031] Specifically, as figure 1 As shown, the template sewing machine includes a frame 1, a head assembly 2 and an XY feeding device 3. Among them, such as figure 2 and image 3 As shown, between the nose assembly 2 and the frame 1, there is a vibration damping structure-4 that can utilize elasticity to provide vibration damping for the nose assembly 2, and the nose assembly 2 passes through the vibration damping structure-4 and the frame. 1 are connected, and the vibration damping structure 1 4 can provide support for the head assembly 2; the vibration damping structure 2 5 that can provide vibration damping for the XY feeding device 3 by using elasticity is provided between the XY feeding device 3 and the frame 1, The XY feeding device 3 is connected to the frame 1 through the vibration-damping structure 2 5 , and the vibration-damping structure 2 5 can provide support for the XY feeding device 3 . A connecting piece 6 is provided between the head assembly 2 and the XY ...

Embodiment 2

[0036] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, the vibration damping structure 4 includes a support plate 41, a screw 42 and a screw located inside the support plate 41. Vibration damping pad 1 43, support plate 1 41 are fixedly connected with the frame 1, screws 1 42 pass through support plate 1 41, vibration damping pad 1 43 in sequence and penetrate into the base 2a to lock and connect with the base 2a; or, The damping structure-4 comprises a support plate-41, a screw-42 and a damping pad-43 positioned at the outside of the support plate-41, the support plate-41 is fixedly connected with the frame 1, and the screw-42 passes through the vibration-damping pad-43 successively , Support plate one 41 and penetrate into the base 2a to lock and connect with the base 2a.

Embodiment 3

[0038] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, the vibration-damping structure 2 5 includes a support plate 51, a screw 52 and a screw located inside the support plate 51. Damping pad 2 53, support plate 2 51 is fixedly connected with frame 1, screw 2 52 passes through support plate 2 51, vibration damping pad 2 53 in turn and penetrates into the base 31 and is locked and connected with the base 31; Alternatively, the vibration-damping structure 2 5 includes a support plate 2 51, a screw 2 52 and a vibration-damping pad 2 53 positioned outside the support plate 51, the support plate 2 51 is fixedly connected with the frame 1, and the screws 2 52 pass through the vibration-damping pad in turn Two 53. The support plate two 51 penetrates into the base 31 and is tightly connected with the base 31 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com