Full closed-loop control method for multi-shaft linked dynamic correction of interpolation positions

A dynamic correction, multi-axis linkage technology, applied in the general control system, program control, computer control and other directions, can solve the problems of reducing the service life of the machine tool, affecting the machining accuracy of the workpiece, and the machining speed is not stable, so as to improve the machining accuracy, dynamic Good stability and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

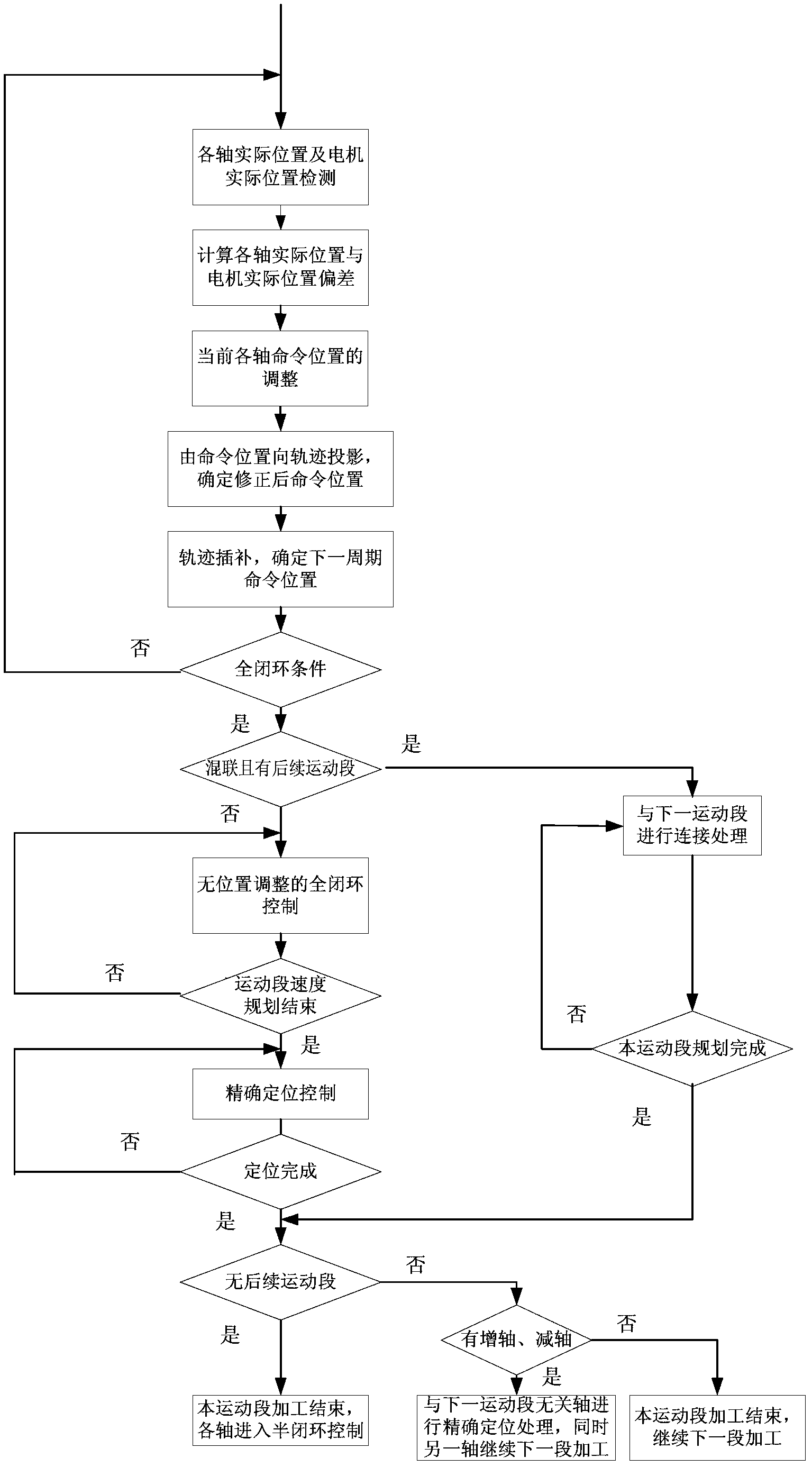

[0050] The full-closed-loop motion control of multi-axis linkage dynamic correction includes: 1) Adjust the command position of each axis according to the deviation between the collected actual position of each axis and the actual position of the motor; 2) Map the adjusted command position of each axis into a trajectory command position on the .

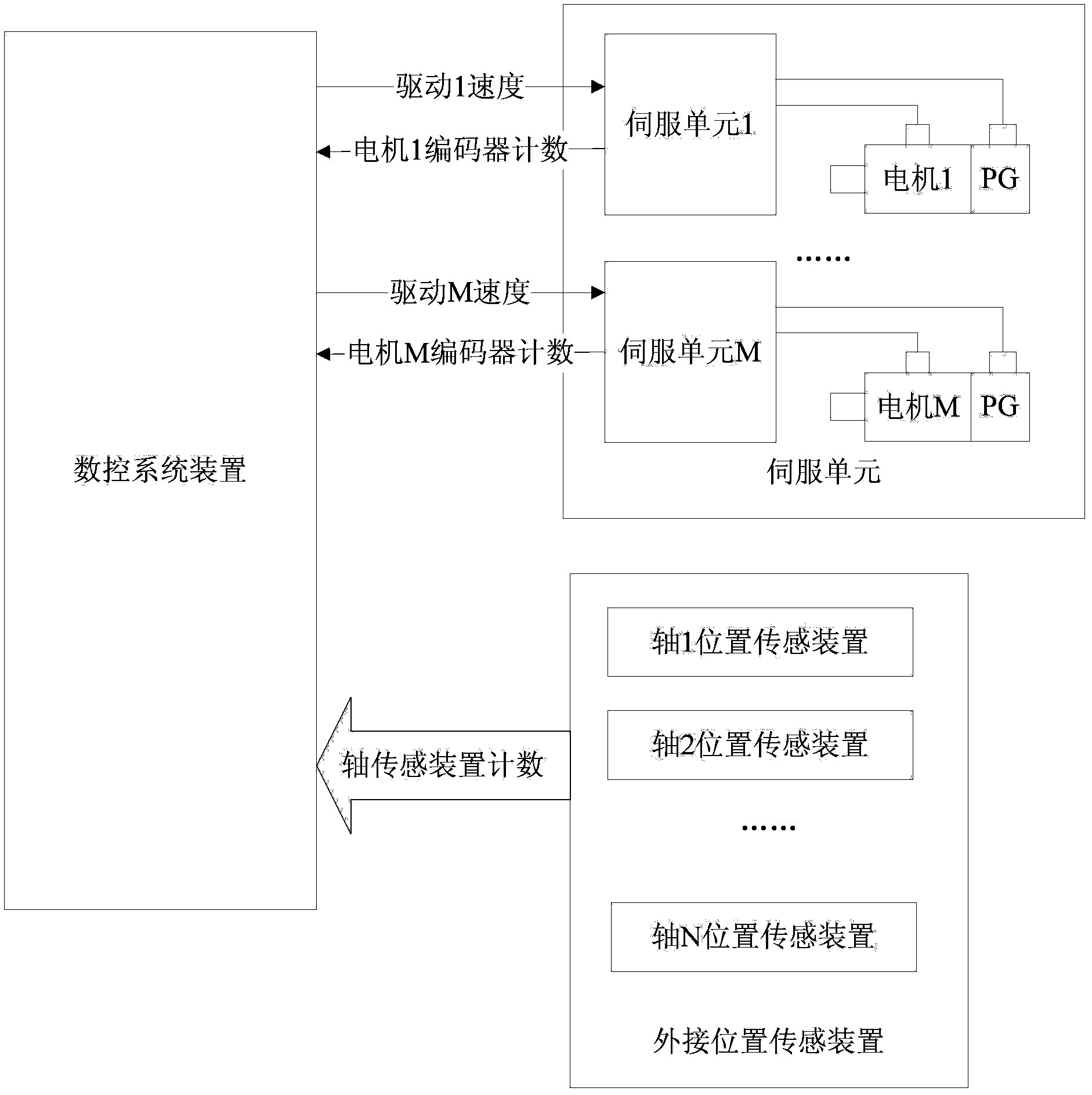

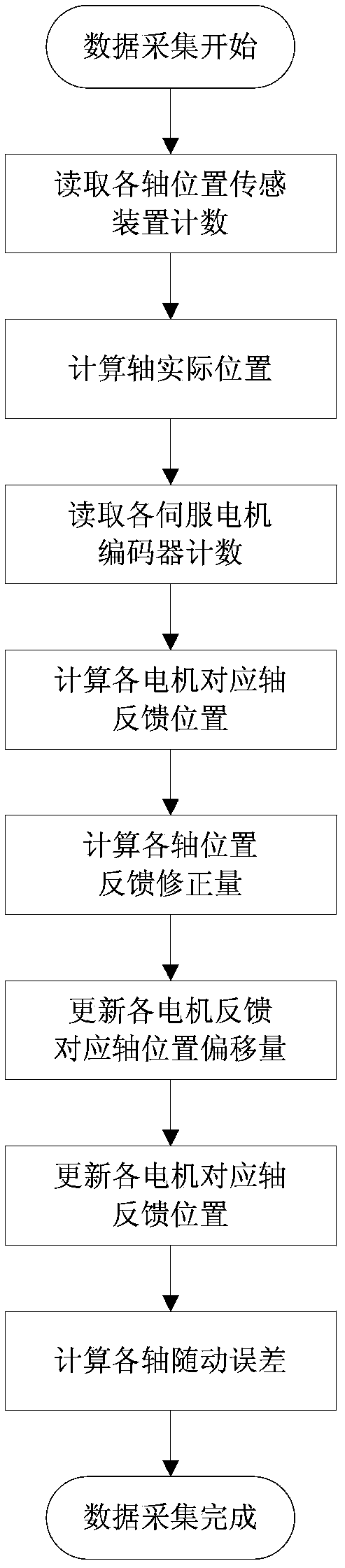

[0051]Among them, the data acquisition and deviation calculation are realized based on the double feedback method of motor and machine tool position. Breaking the concept of traditional motion trajectory planning, the axis feedback position obtained by the external position sensing device such as the grating scale at the final execution end of the machine tool axis, and the axis feedback position calculated by the feedback of the servo motor encoder, the difference between the two is the axis motion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com