Rubbing rod head, rod rubbing device and tripping method for coal mine power head drilling rig

A technology of power head and rod device, which is applied in the direction of drill pipe, drill pipe, earthwork drilling, etc., can solve the problem of low efficiency of loading and unloading drill pipe, and achieve the effect of reducing labor intensity of workers, rapid movement, and large contraction stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

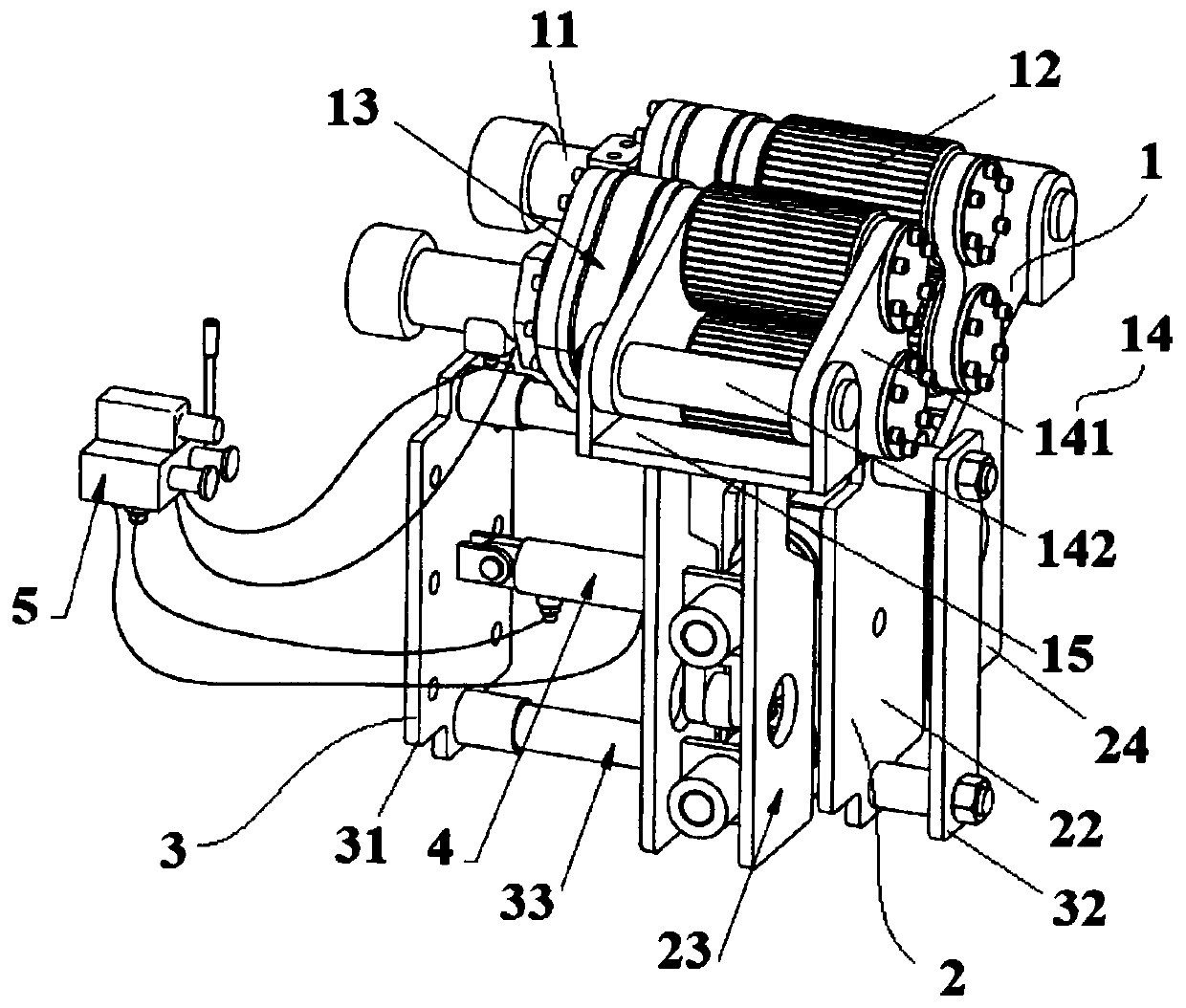

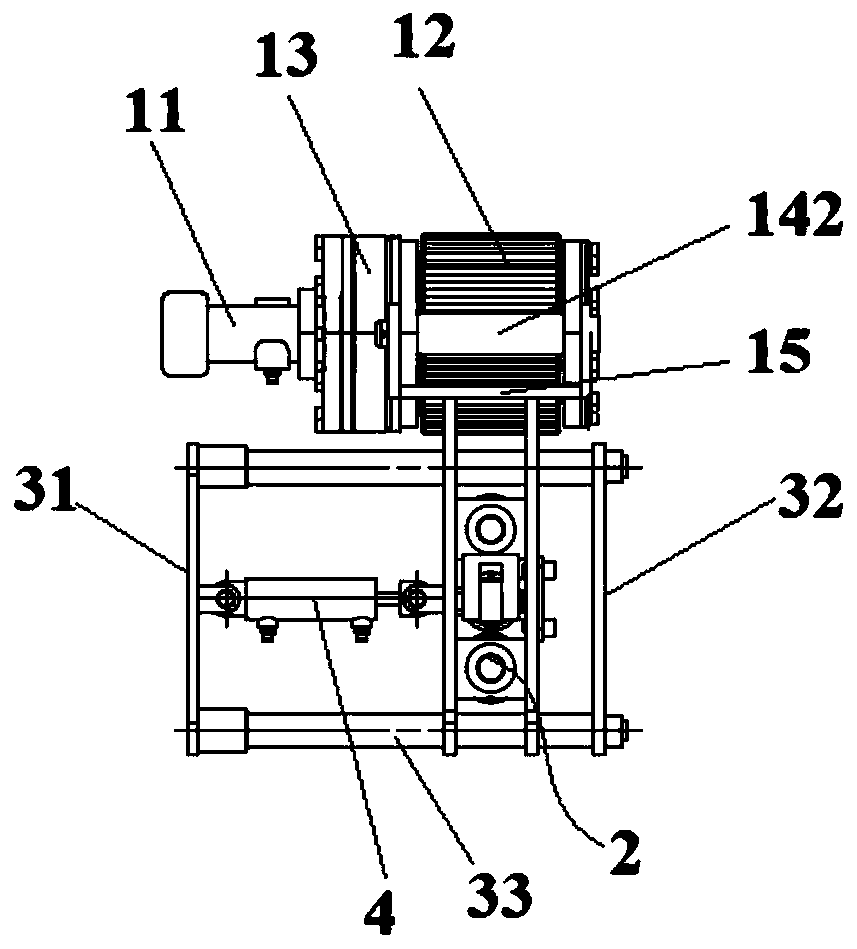

[0050] Such as Figure 5As shown, the present embodiment provides a rubbing rod head, comprising a motor 11, a first gear mounted on the shaft of the motor 11, two rubbing wheels 12, and a second gear mounted on the shafts of the two rubbing wheels 12 respectively and the third gear; the motor 11 and the two rubbing wheels 12 are parallel to each other, and the first gear meshes with the second gear and the third gear respectively; the first gear, the second gear and the third gear are all installed on the gear In the box 13, and the motor 11 and the rubbing wheel 12 are respectively installed in the gear box 13 both sides.

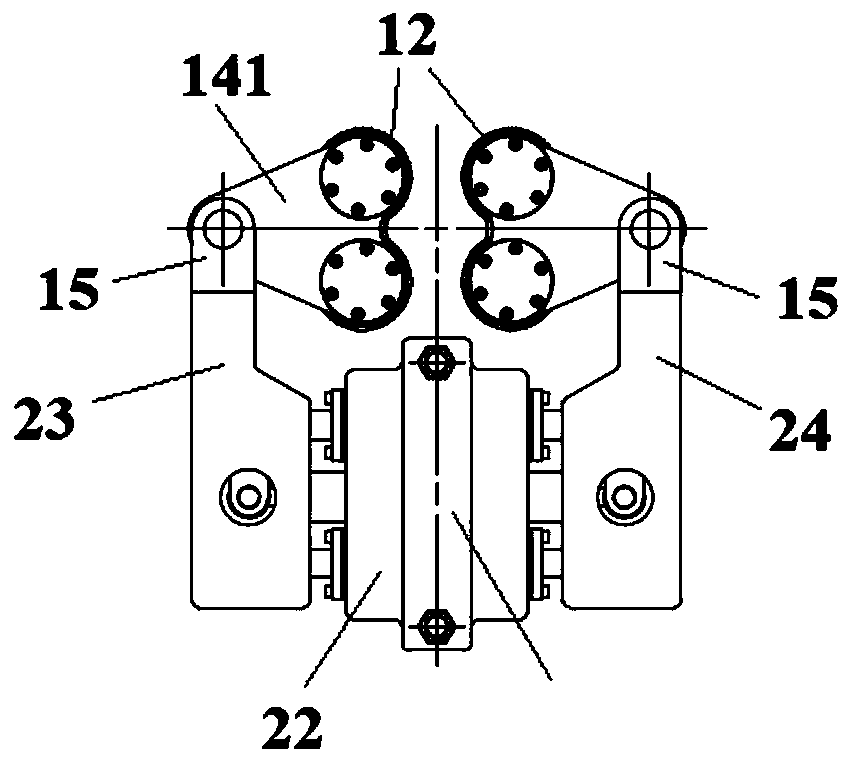

[0051] In this embodiment, two rubbing wheels 12 are provided with a rubbing frame 14; the rubbing frame 14 includes two parallel fixed plates 141 and a connecting rod 142, and the connecting rod 142 and the two rubbing wheels 12 are installed vertically. Between the two fixing plates 141 ; one of the fixing plates 141 fits a side wall of the gear box 13...

Embodiment 2

[0054] Such as Figure 1 to Figure 7 As shown, the present embodiment provides a rod rubbing device for a power head drilling machine in a coal mine. The power head drilling machine in this embodiment is a main shaft through-hole type power head drilling machine, and the device includes two rubbing rods described in Embodiment 1. The head is used for clamping and driving the drill pipe to rotate, and also includes a clamping unit 2 installed under the two rubbing rod heads 1, a carriage 3 and an integrated valve group 5 for installing and supporting the clamping unit 2; The rubbing wheels 12 of each rubbing rod head 1 are relatively arranged and are all parallel to each other, and the plane where the two rubbing wheels 12 of the same rubbing rod head 1 is parallel to the plane where the two rubbing wheels 12 of another rubbing rod head 1 is located; the clamping unit 2 Including the center plate, the center plate is respectively connected with the left side plate and the right...

Embodiment 3

[0066] This embodiment also provides a tripping method matched with the rod rubbing device, wherein, as Figure 7 As shown, the tripping equipment matched with the rod rubbing device is conventional equipment, and the tripping equipment matched with the rod rubbing device includes: a lifting arm 6 for hoisting the drill rod 71, for storing The drill rod frame 7 of the drill rod 71, the drill power head 8 and the clamper 10, and the power head 8 and the clamper 10 are coaxially installed on the feed body 9; the installation base 31 of the rod rubbing device is installed on Feed the end of the fuselage 9, so that the rod rubbing device, the power head and the holder are installed coaxially in sequence, more specifically, the drill rod 71 clamped between the two rubbing rod heads 1 of the rod rubbing device and the power The drill rod 71 clamped by the head 8 is arranged coaxially.

[0067] The drilling method supporting the rod rubbing device includes the following three steps:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com