Incinerator gas path structure

An incinerator and gas path technology, applied in the field of incinerators, can solve the problems of inability to deal with carbon monoxide, the heat of exhaust gas is not utilized, etc., and achieve the effects of adjustable heat dissipation, increased heat, and improved heat utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

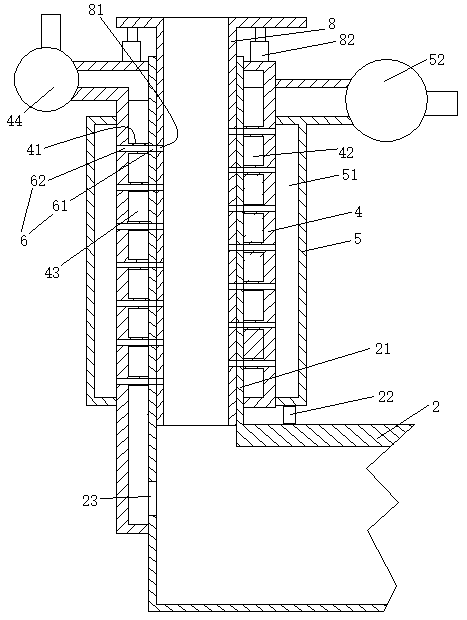

[0015] see figure 1 , an incinerator gas path structure, including an incinerator 2. The incinerator is provided with a chimney 21 , an air inlet 22 and a gaseous fuel inlet 23 . The chimney jacket is provided with a middle pipe 4 . The outer tube 5 is arranged on the outer tube of the middle tube. A fuel chamber 41 is formed between the middle pipe and the exhaust pipe. The fuel chamber is provided with a spiral guide piece 42 with the center line of the chimney as the center line. The spiral guide piece forms a spiral gas channel 43 in the fuel chamber. One end of the gas passage is connected with the gas fuel inlet, and the other end is connected with the outlet of the fuel delivery pump 44 . The part of the chimney inside the middle pipe is made of heat-conducting material. An air chamber 51 is formed between the outer tube and the middle tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com