Mandrel type casing pipe hanger load testing method

A load test and hanger technology, applied in the testing of machines/structural components, testing of mechanical components, instruments, etc., can solve problems such as the inability to guarantee the effectiveness, safety and reliability of the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] based on the following Figure 1 ~ Figure 2 , specifically explain the preferred embodiment of the present invention.

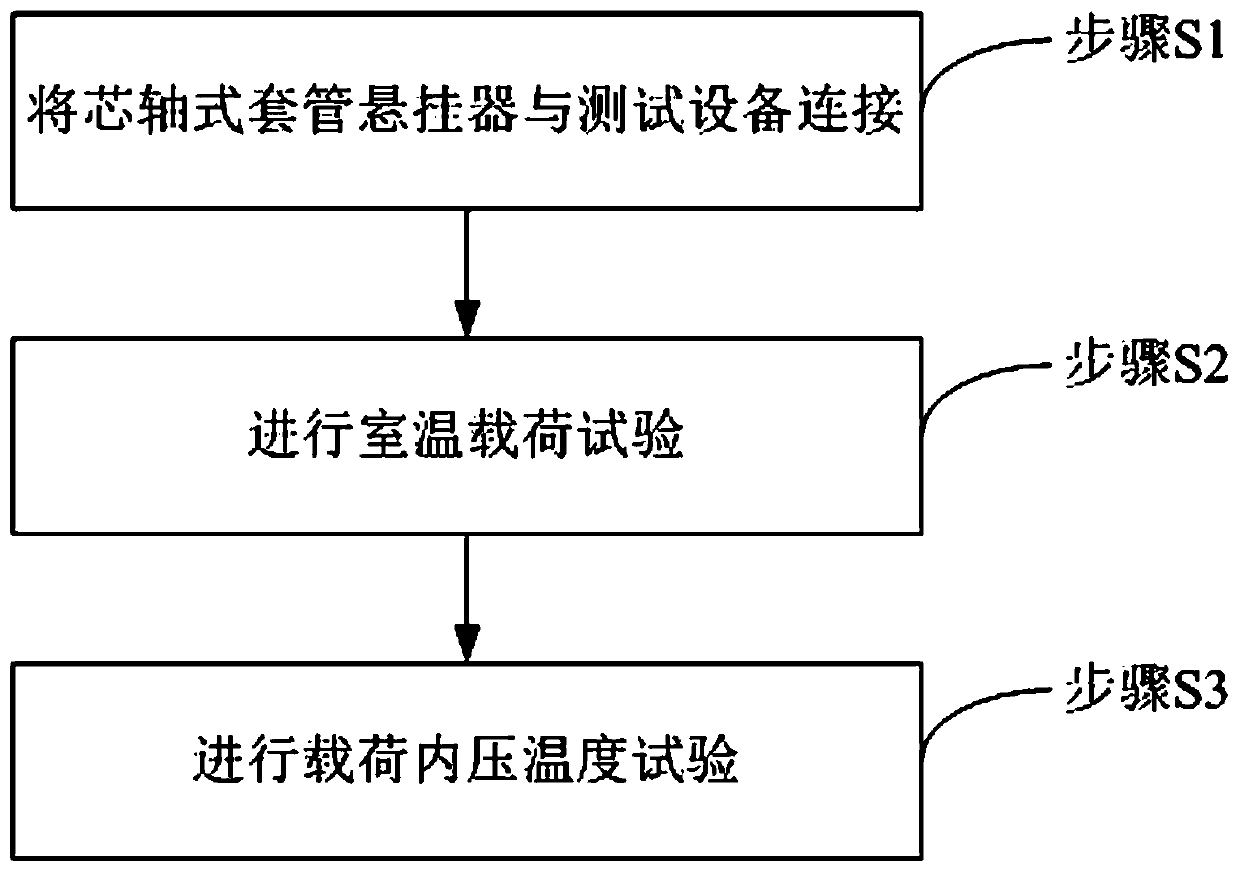

[0041] Such as figure 1 As shown, the present invention provides a kind of mandrel type casing hanger load testing method, comprises the following steps:

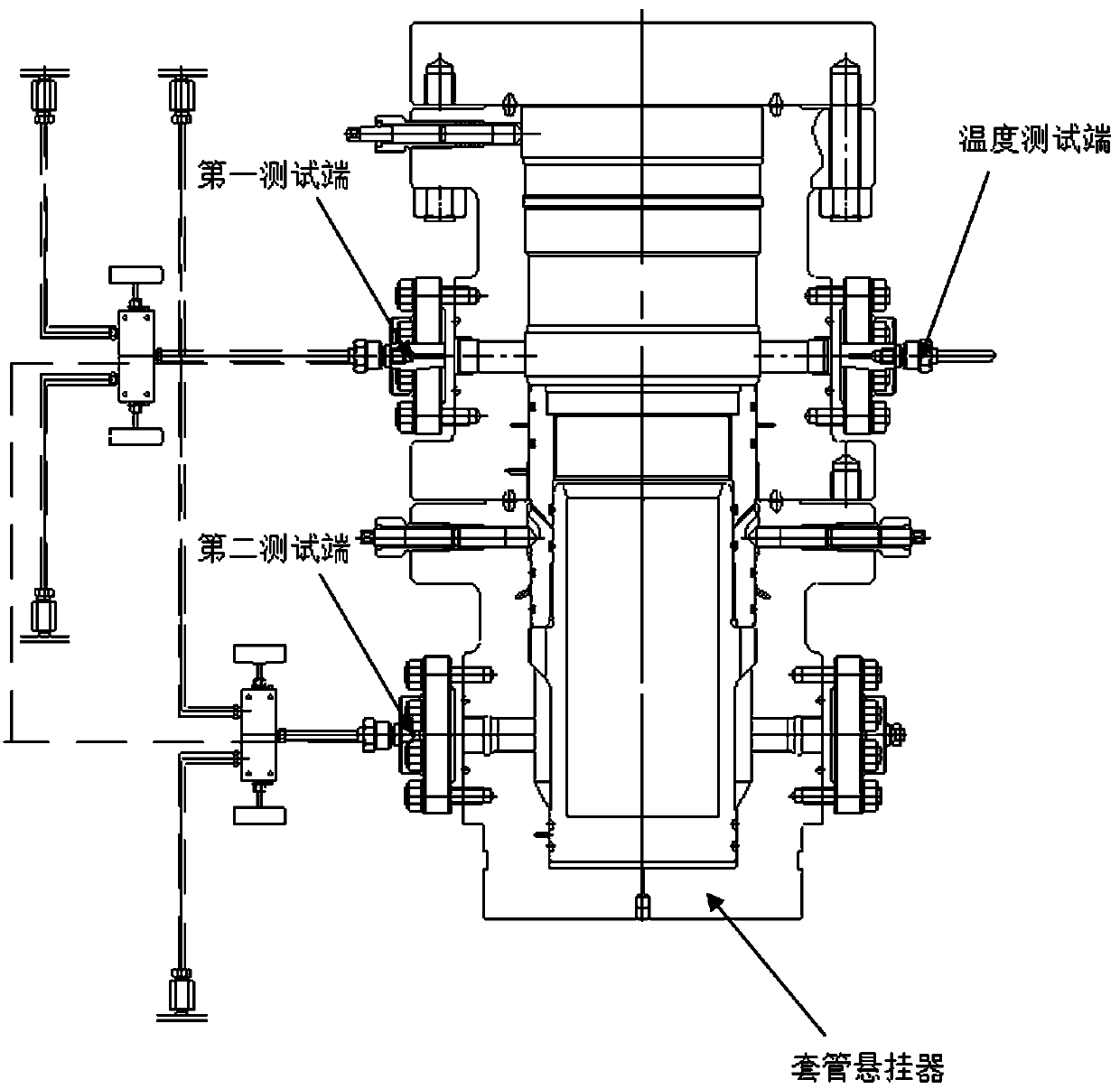

[0042] Step S1, such as figure 2 As shown, put the mandrel casing hanger into the high and low temperature box, lead the first test end from the upper chamber of the mandrel casing hanger, and lead the second test end from the lower chamber of the mandrel casing hanger. Two test terminals, the first test terminal and the second test terminal are connected to the test gas pipeline, the test gas pipeline is provided with a pressure measuring instrument, and the temperature measurement equipment is connected to the temperature test terminal of the mandrel casing hanger;

[0043] Step S2, carrying out a load test at room temperature, and testing the minimum rated load and maximum rated load of the m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap