Automatic detecting device for high voltage box tooling

An automatic detection device and high-voltage box technology, which is applied to measuring devices, testing electrical devices in transportation, measuring electricity, etc., can solve the problems of low detection efficiency, increase the production cost of high-voltage boxes, and consume a lot of manpower and material resources, so as to save manpower The effect of reducing material resources, reducing production costs, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

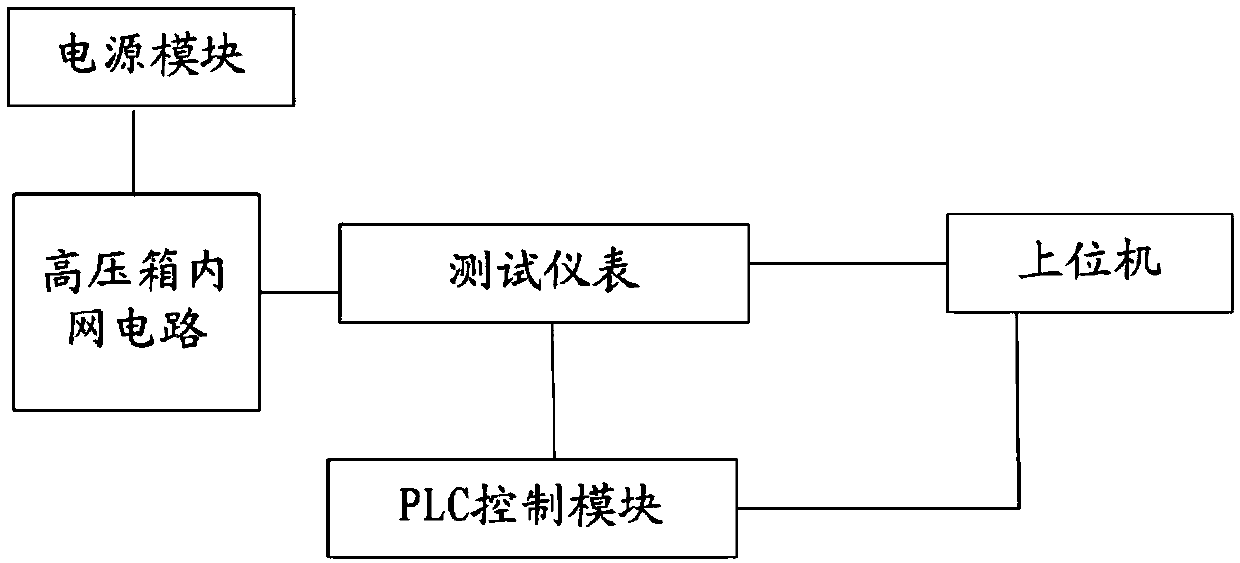

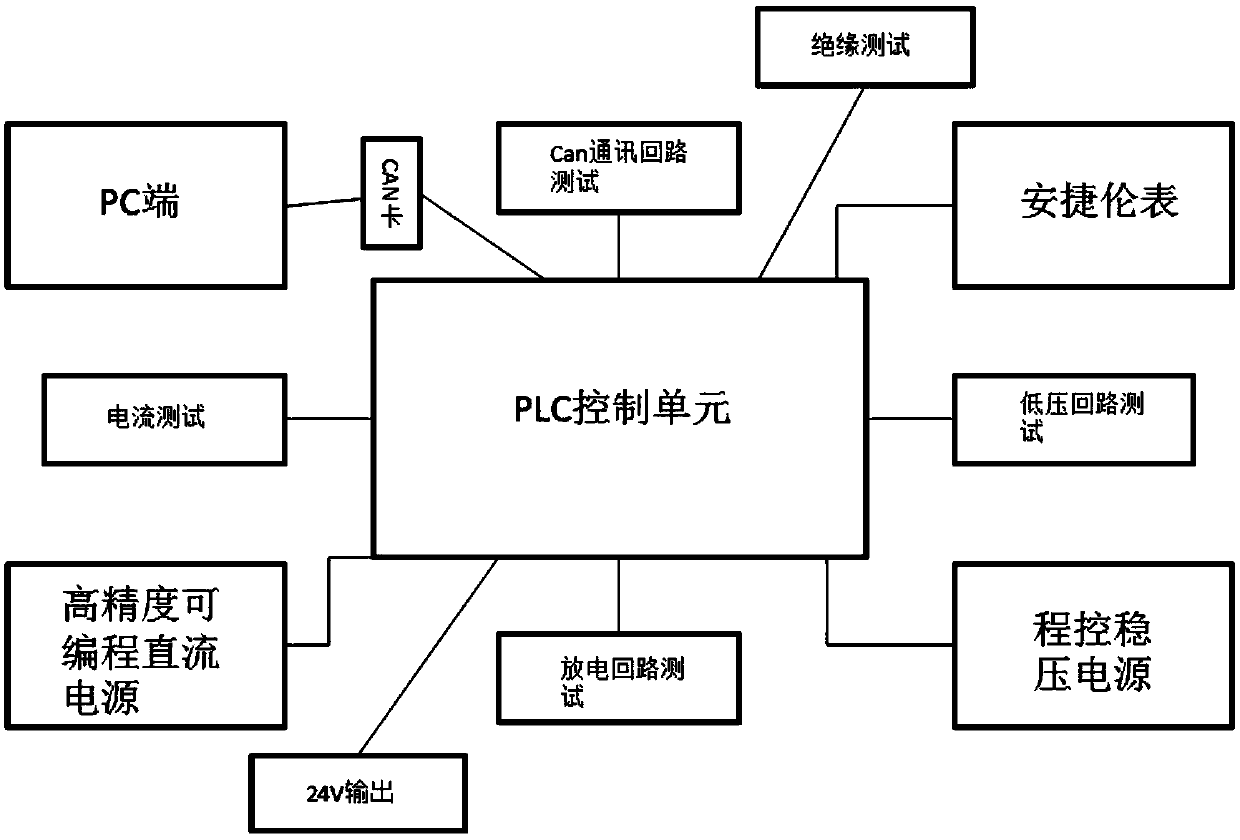

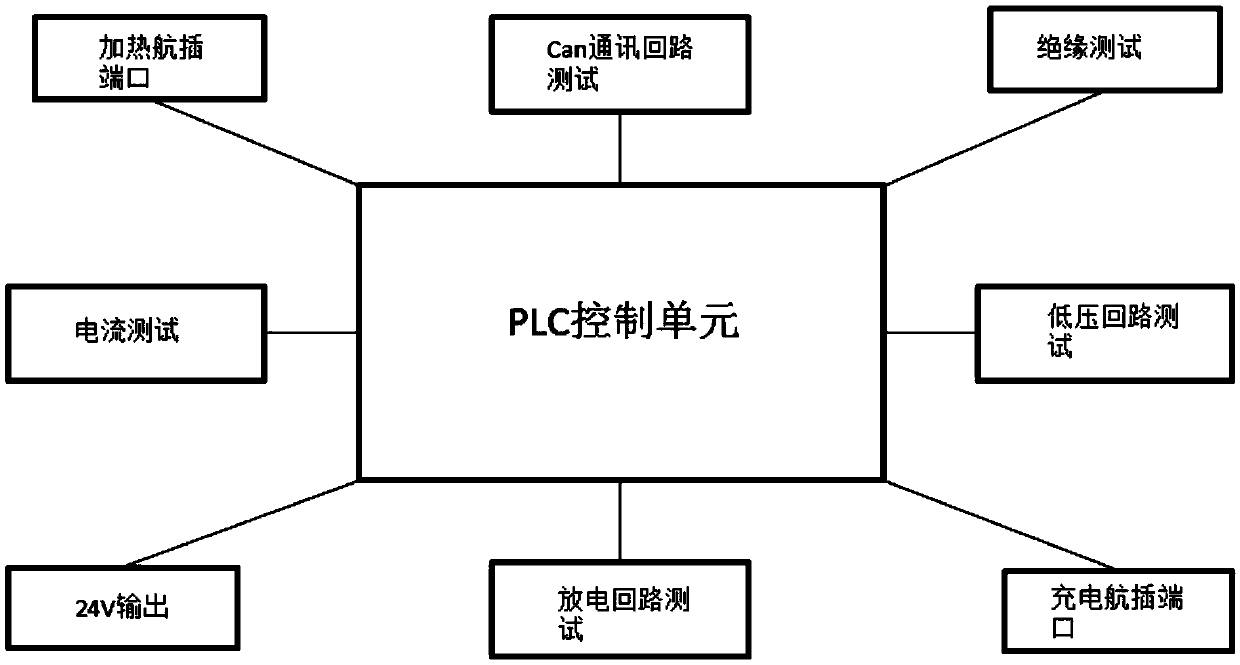

[0043] see Figure 1 to Figure 3 , the present invention provides an automatic detection device for high-voltage box tooling, comprising:

[0044] The power module is used to supply power to the internal network circuit of the high voltage box;

[0045] The test instrument is used to collect the loop voltage value, loop current value and loop resistance value in the preset detection loop, and then transmit it to the host computer through the CAN (controller area network) card;

[0046]The upper computer is connected with the test instrument through the CAN card, and is used to receive the loop voltage value, loop current value and loop resistance value in the preset detection circuit transmitted by the test instrument, and then judge whethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com