The invention discloses a mMarine diesel engine mechanism heavy part machining quality prediction method based on digital twinning

A technology of processing quality and prediction method, which is applied in the direction of prediction, data processing applications, instruments, etc., can solve problems such as difficult processing, lagging processing quality inspection, and insufficient connection between virtual and physical spaces, so as to improve resource utilization and improve The effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing.

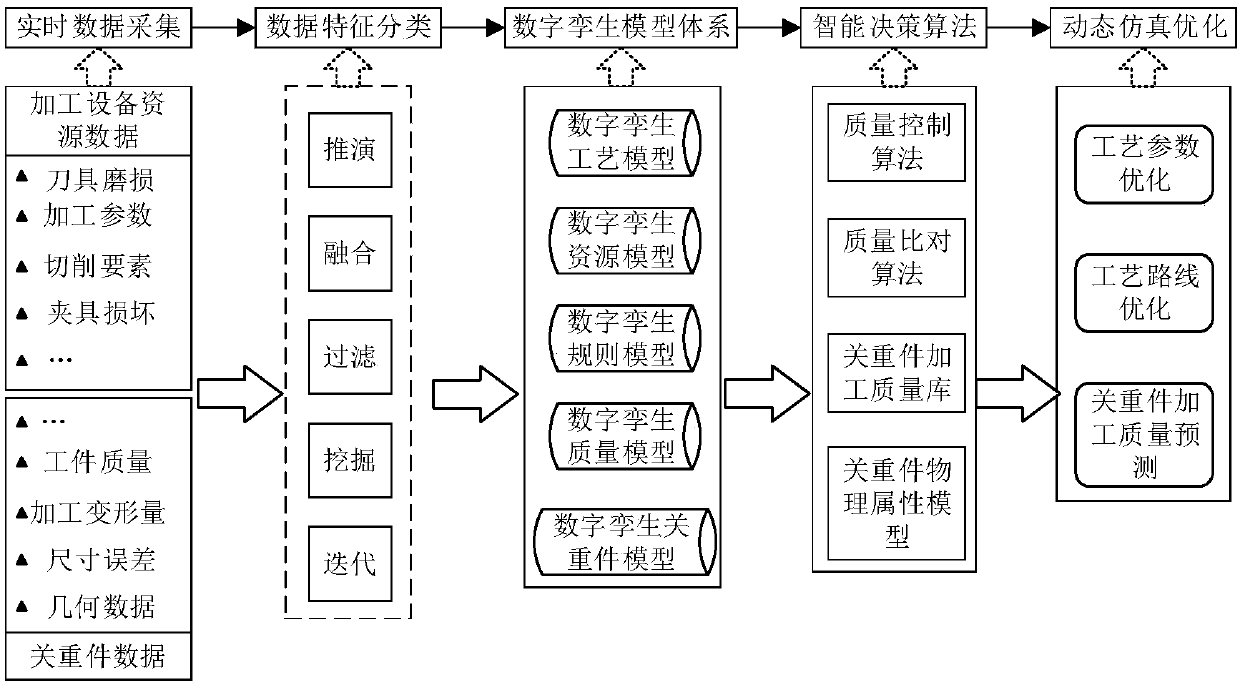

[0042] Such as figure 1 Shown, the present invention comprises the following steps:

[0043] (1) Real-time data collection of heavy parts of marine diesel engines and processing resource equipment in the process of processing through sensors, RFID, actuators, etc., placing sensors on physical entities, real-time, real-time, and manufacturing of heavy parts of marine diesel engines Dynamic data collection. The real-time processing data collected during the processing of heavy parts of marine diesel engines include: geometric dimensions, geometric errors, shape and position errors, shape data, processing deformation and workpiece surface quality. Among them, the machining deformation of heavy parts of marine diesel engines is used as the criterion for judging the quality of the current process of the workpiece. Processing resource equipment data mainly includes: tool wear,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com