The invention discloses an iIntegrated production task scheduling method for task reliability

A technology of production tasks and scheduling methods, applied in the direction of comprehensive factory control, data processing application, forecasting, etc., to achieve the effect of improving enterprise production efficiency and product competitiveness, and improving scientificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

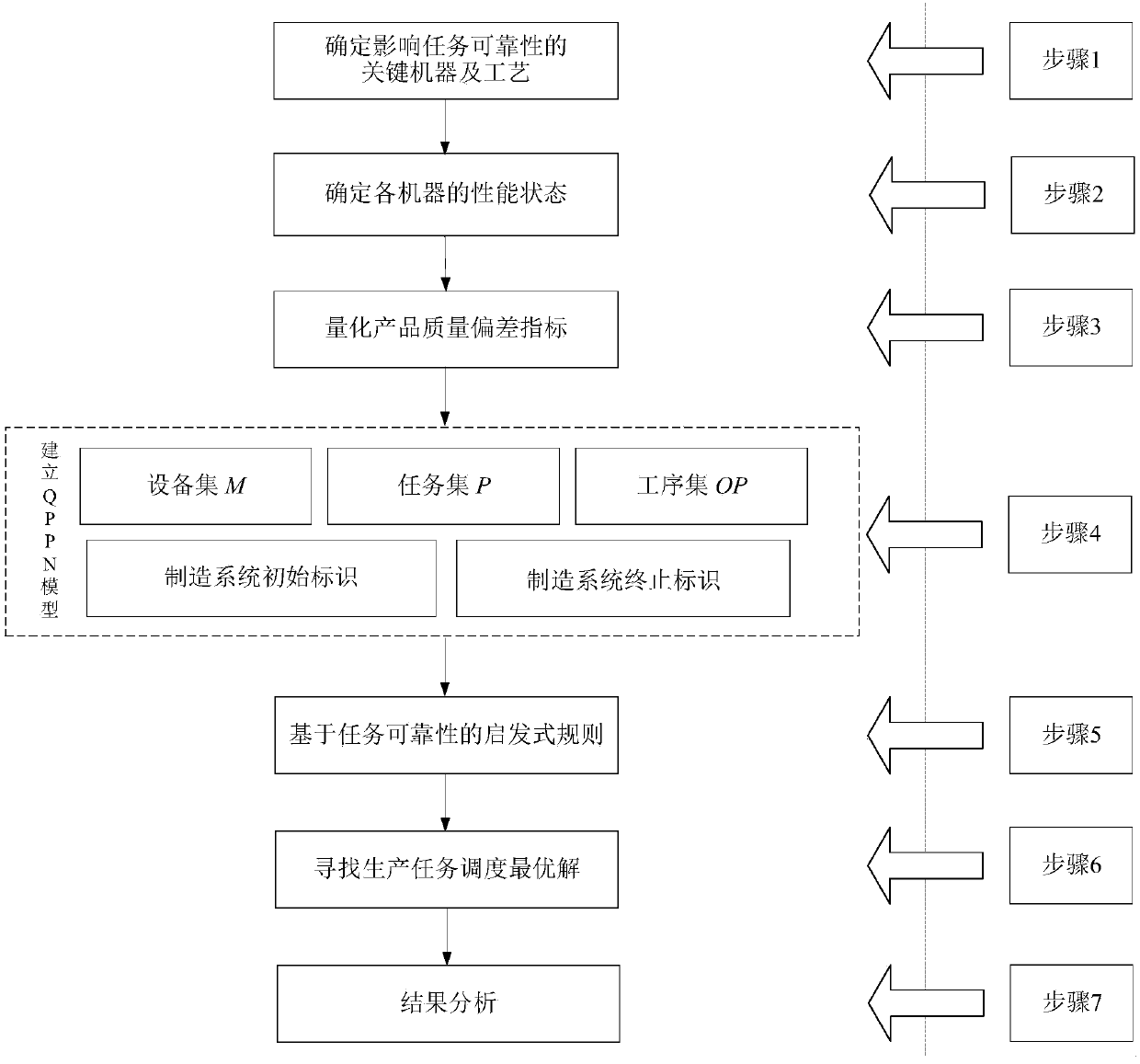

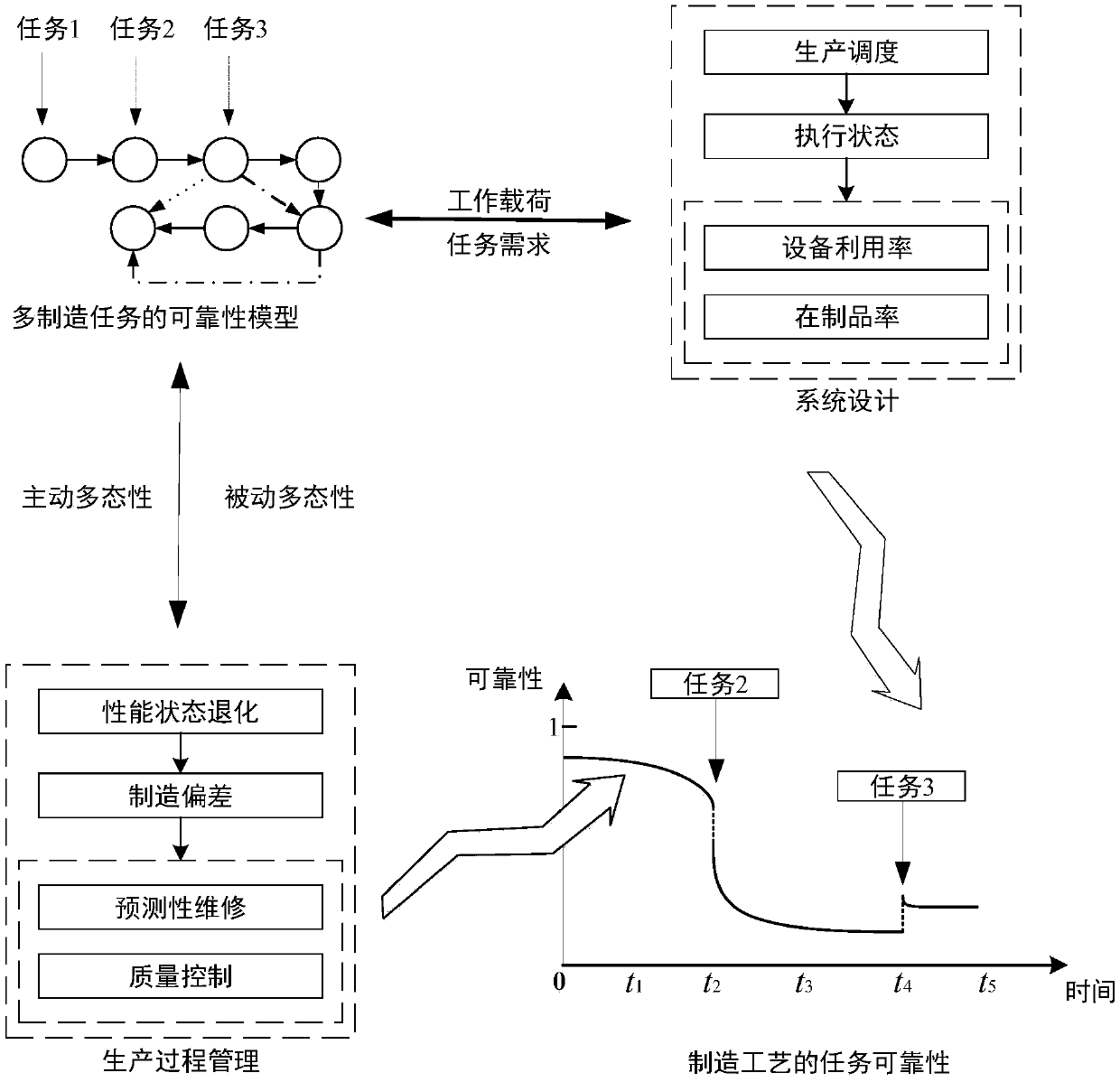

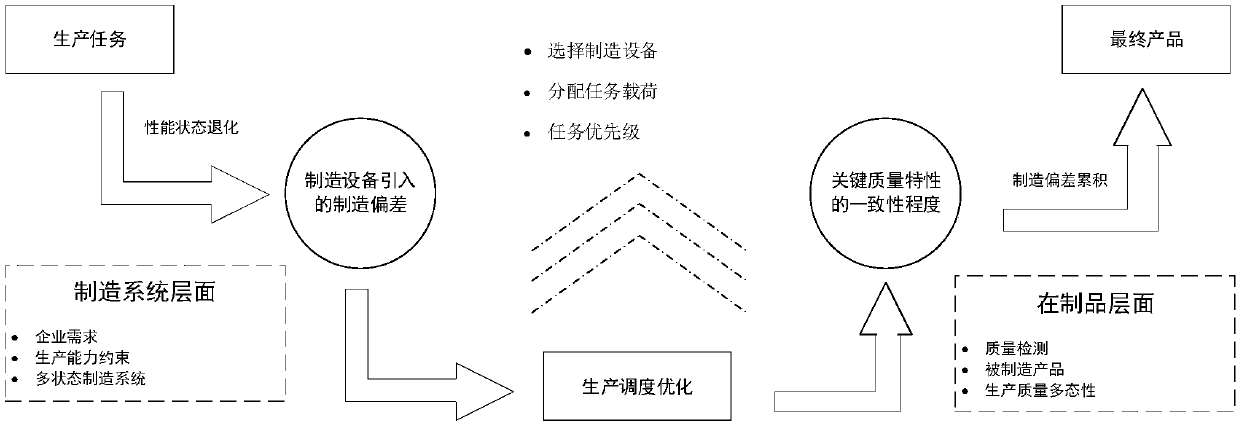

[0084] The present invention is an integrated production task scheduling method oriented to task reliability, the flow chart of which is shown in figure 1 As shown, the schematic diagram of the scheduling mechanism is shown in figure 2 As shown, the schematic diagram of the mission reliability concept model is shown in image 3 As shown, the specific implementation steps are as follows:

[0085] Step 1 Collect the manufacturing process data and process quality data of a certain type of engine cylinder head, identify the key process and production equipment of the cylinder head manufacturing system, and determine the key quality characteristics and requirements, see Table 1 below.

[0086] Table 1. Critical quality characteristics and their manufacturing process information

[0087]

[0088] Step 2 Select processes 3, 4, and 5 as the research o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com