Method for preparing pre-solid post-slurry soy sauce by using synergetic fermentation of lactic acid bacteria and yeast

A production method and collaborative fermentation technology, applied in food science and other directions, can solve the problems of high cost of raw materials, low utilization rate of raw materials, and undiscovered patent publications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for making soy sauce that is first solidified and then thinned by co-fermentation with lactic acid bacteria and yeast, the steps are as follows:

[0033] (1) Soak soybean meal and corn in boiling water for 30 minutes, add bran and stir evenly, steam at 0.15-0.2 MPa for 30 minutes;

[0034] Wherein, the moistening amount is 110-120% of the total weight of raw materials; the parts by weight of soybean meal, corn and bran are: 50 parts of soybean meal, 30 parts of corn, and 20 parts of bran;

[0035] (2) Stir and mix the cooked raw materials to 38-43°C, and add soy sauce koji essence according to 0.3-0.5% of the total weight of raw materials;

[0036] (3) Make koji according to the production method of soy sauce koji;

[0037] (4) mixed with brine with a mass concentration of 10-12%, the mass ratio of the total amount of raw materials: brine is 1:1-1.2;

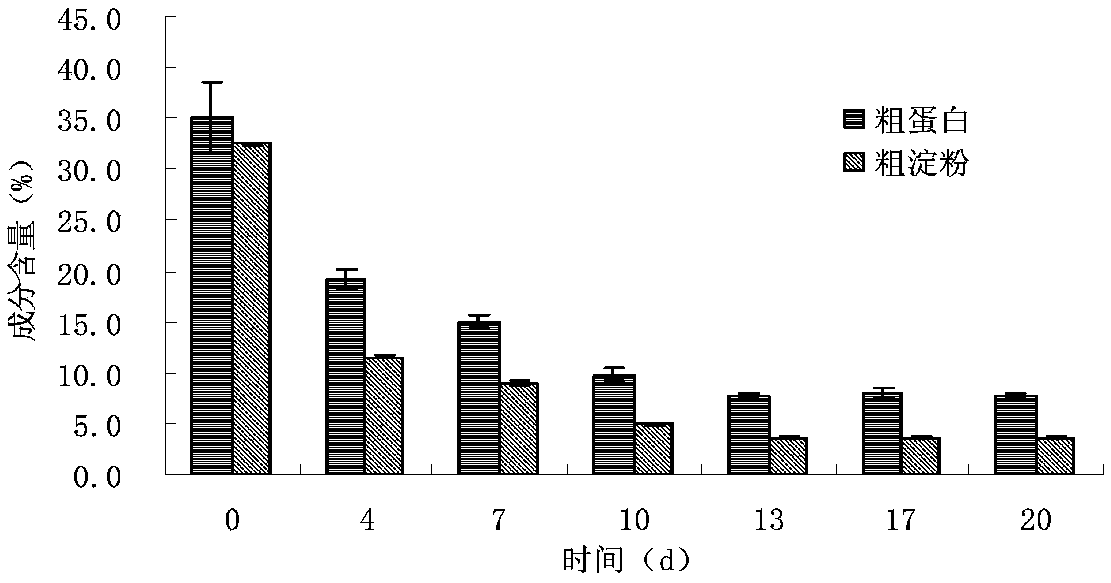

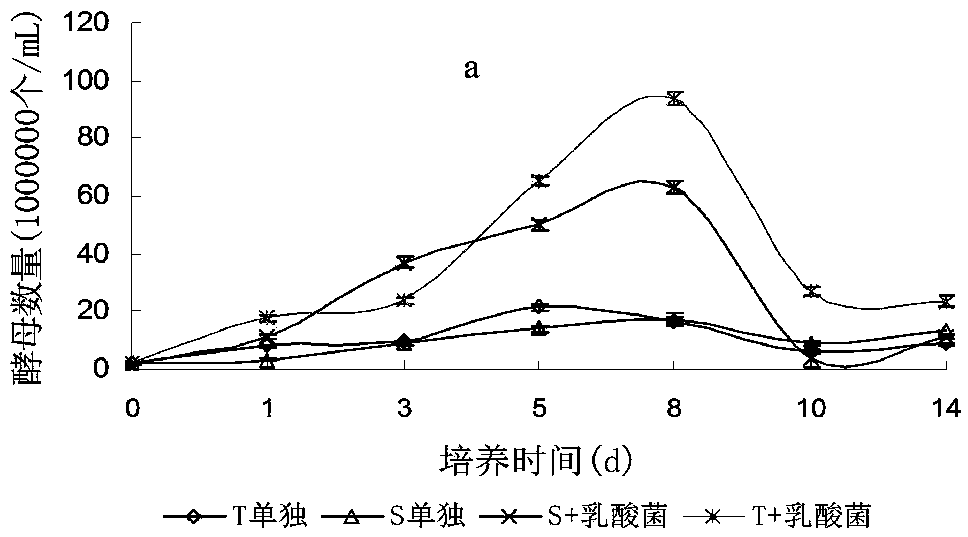

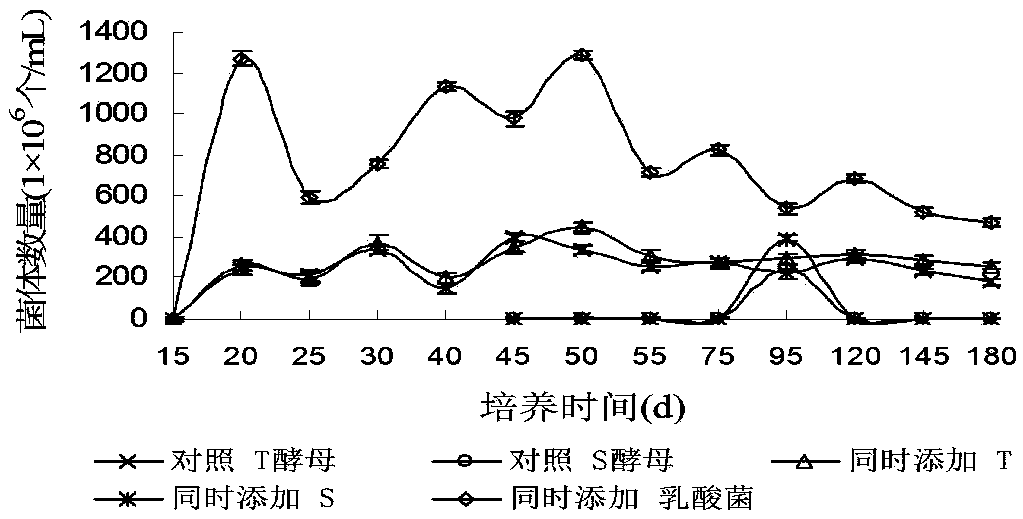

[0038] (5) During the hydrolysis stage, the fermentation temperature is controlled at 43°C, and the fermenta...

Embodiment 2

[0044] A method for making soy sauce that is first solidified and then thinned by co-fermentation with lactic acid bacteria and yeast, the steps are as follows:

[0045] (1) Soak soybean meal and corn in boiling water for 30 minutes, add bran and stir evenly, steam at 0.15-0.2 MPa for 30 minutes;

[0046] Wherein, the moistening amount is 110-120% of the total amount of raw materials; the parts by weight of soybean meal, corn and bran are: 50 parts of soybean meal, 40 parts of corn, and 10 parts of bran;

[0047] (2) Stir and mix the cooked raw materials to 38-43°C, and add soy sauce koji essence according to 0.3-0.5% of the total weight of raw materials;

[0048] (3) Make koji according to the production method of soy sauce koji;

[0049] (4) mixed with brine with a mass concentration of 10-12%, the mass ratio of the total amount of raw materials: brine is 1:1-1.2;

[0050] (5) During the hydrolysis stage, the fermentation temperature is controlled at 43°C, and the fermenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com