Mercury sphygmomanometer

A sphygmomanometer and mercury technology, which is applied in the field of sphygmomanometers, can solve the problems of taking a long time to store mercury sphygmomanometers, blood pressure measurement deviation of blood pressure measurers, and improper arm placement, etc., achieving long life, no power consumption, and energy saving the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

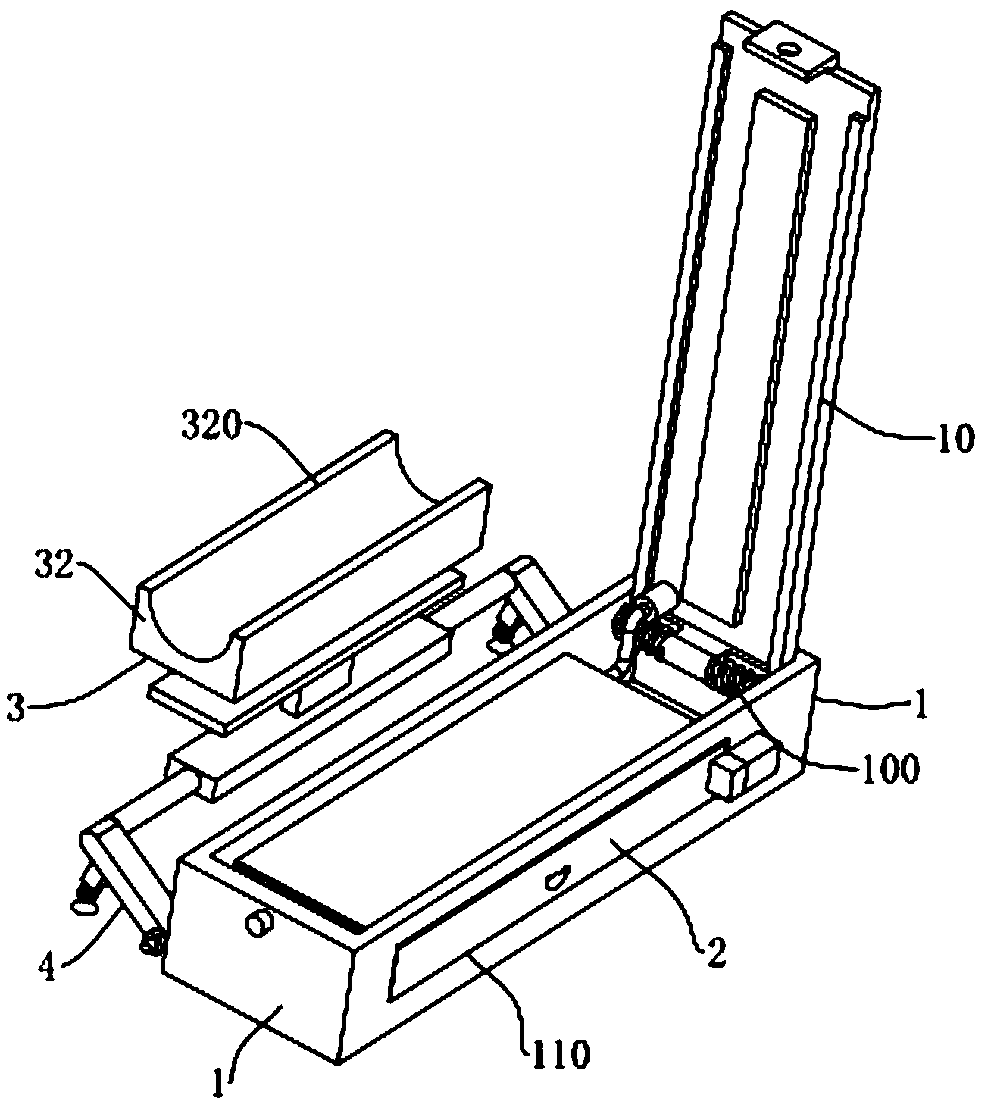

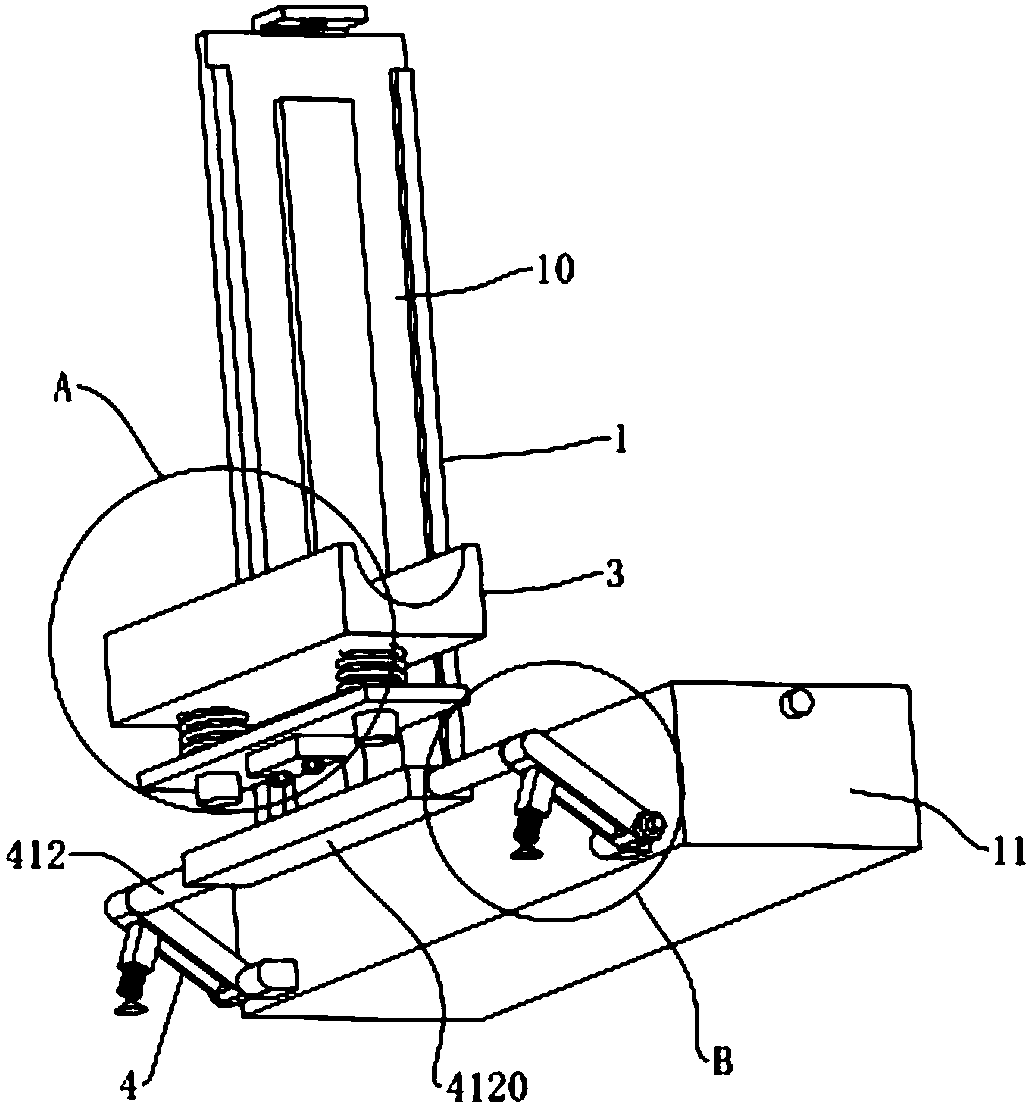

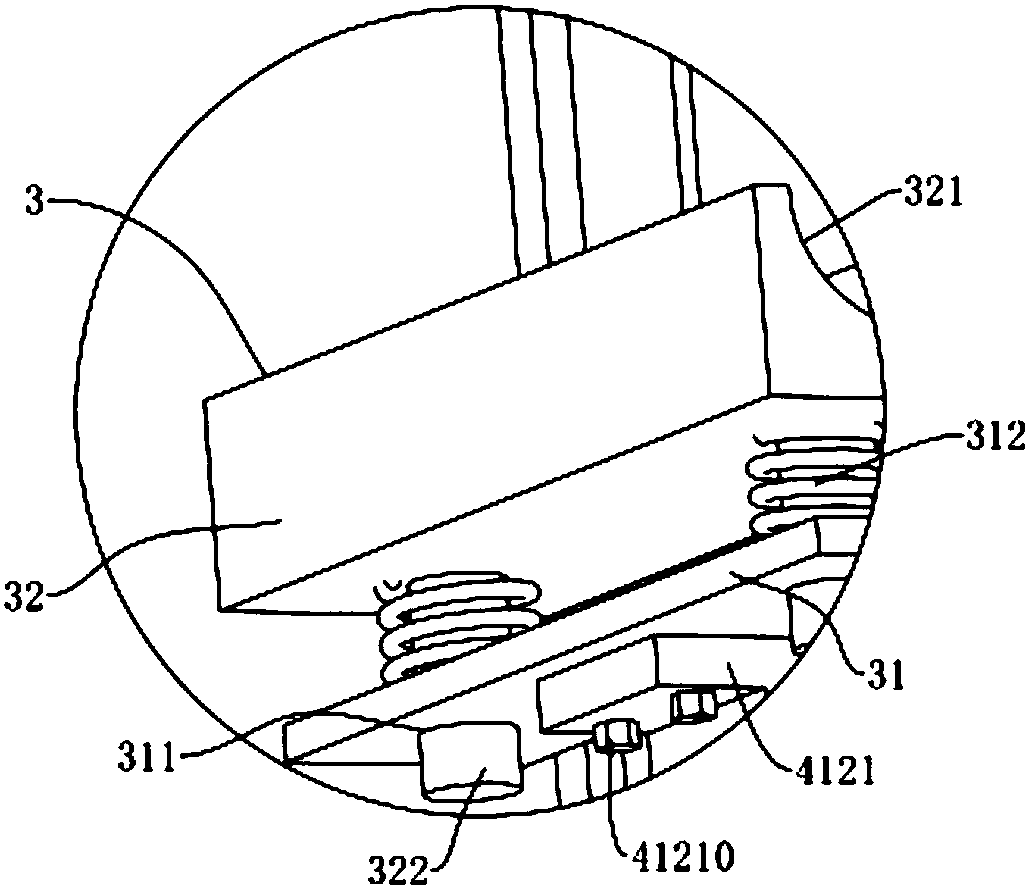

[0048] refer to figure 1 and figure 2 , a mercury sphygmomanometer, including a sphygmomanometer body 1, wherein the upper cover 10 and the lower cover 11 in the sphygmomanometer body 1 are hinged to each other, and the upper cover 10 is clamped and fixed after being closed to the lower cover 11; for convenience The long rubber tube, arm cuff, stethoscope and latex ball in the sphygmomanometer body 1 are stored and the blood pressure measurer is assisted in adjusting the position of the arm. An outlet 110 is opened on the side of the lower cover 11, and the outlet 110 is slidably connected in the lower cover 11. The drawn-out storage box 2 for placing the long rubber tube, arm cuff, stethoscope and latex ball in the blood pressure monitor body 1, wherein the storage box 2 is snapped and locked after being fully inserted into the lower cover 11, and the side of the lower cover 11 is also provided with The arm placement part 3 that is convenient for the arm of the blood pressu...

Embodiment 2

[0057] The difference from Embodiment 1 is that the groove surface of the placement groove 321 is coated with a layer of antifouling coating. Since the mercury sphygmomanometer is in use, many users have to place their arms into the placement groove 321 on the support base 32 Inside, the placement groove 321 is easy to become dirty, in order to facilitate the cleaning of the placement groove 321 groove surface, so a layer of antifouling coating is coated on the placement groove 321 groove surface, so a preparation of an antifouling coating is provided method, which has the advantages of short preparation process and simple preparation, wherein the preparation method of the antifouling coating on the groove surface of the placement groove 321 is as follows:

[0058]Get the following components by weight for subsequent use: 32 parts of polycarbonate, 38 parts of polyurethane, 43 parts of epoxy resin, 21 parts of polyacrylic resin, 13 parts of polyvinyl chloride, 14 parts of glyce...

Embodiment 3

[0065] The difference from Example 2 lies in the preparation of the antifouling coating on the surface of the groove 321, wherein the preparation method of the antifouling coating is as follows:

[0066] Get the following components by weight for subsequent use: 33 parts of polycarbonate, 39 parts of polyurethane, 44 parts of epoxy resin, 22 parts of polyacrylic resin, 14 parts of polyvinyl chloride, 14 parts of glycerol, acrylic acid 11 parts of sodium, 8 parts of polyacrylamide, 8 parts of sodium benzoate;

[0067] S1, carry out surface treatment to the placement tank 321 groove surface: first utilize the method for sandblasting to remove the dust, grease and oxide skin on the placement groove 321 surface, use the quartz sand that sand grain diameter is 2mm during sand blasting, then place the groove 321 groove surface Grinding with sandpaper, grinding the groove surface to R7 level of roughness;

[0068] S1. Preparation of antifouling coating pre-preparation solution: mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com