A kind of chip cleaning equipment used in mechanical processing plants

A technology for cleaning equipment and processing plants, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of time-consuming and labor-intensive cleaning personnel, affecting production efficiency, reducing processing speed, etc., to achieve low production costs, Full-featured, easy-to-install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

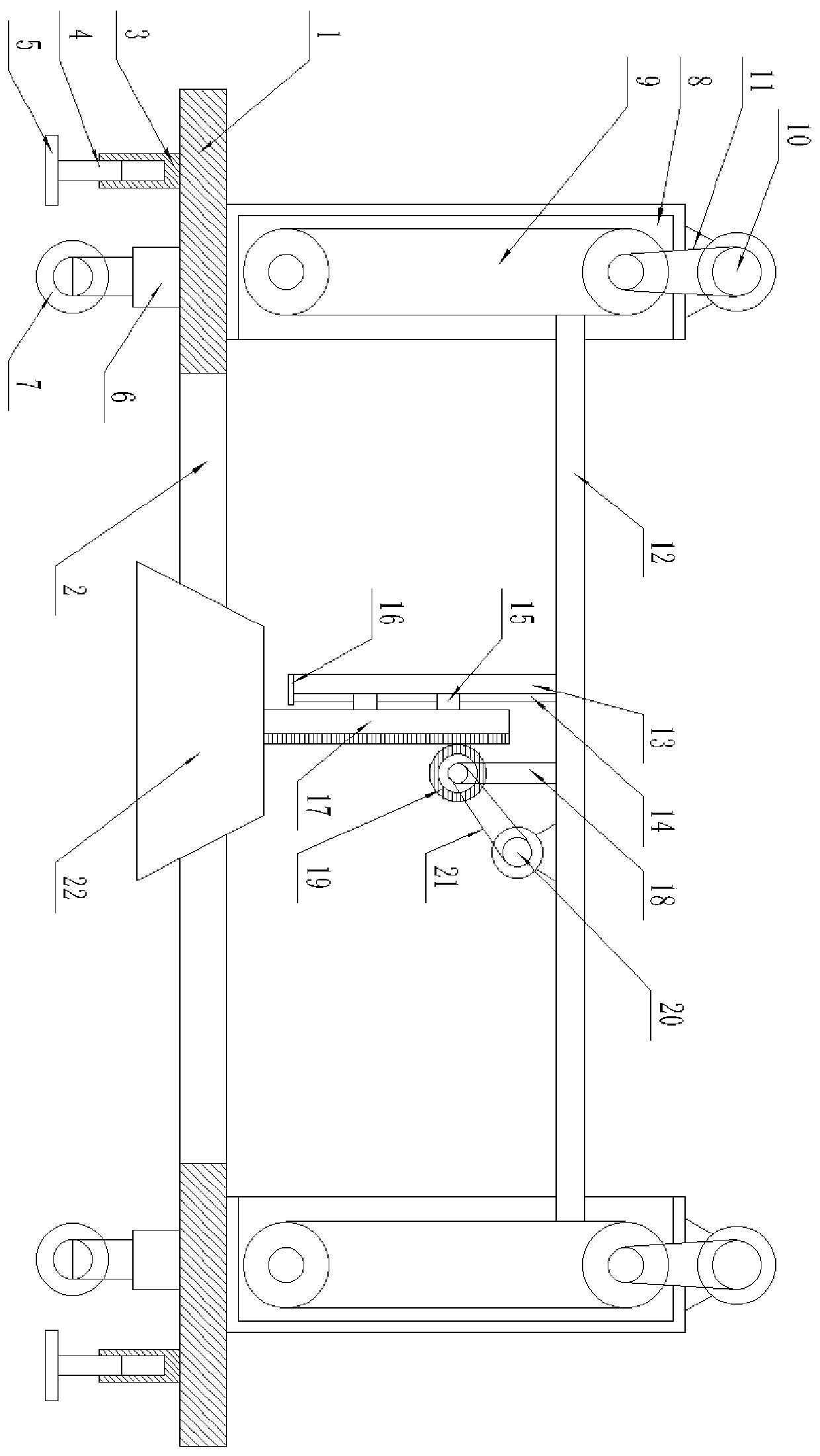

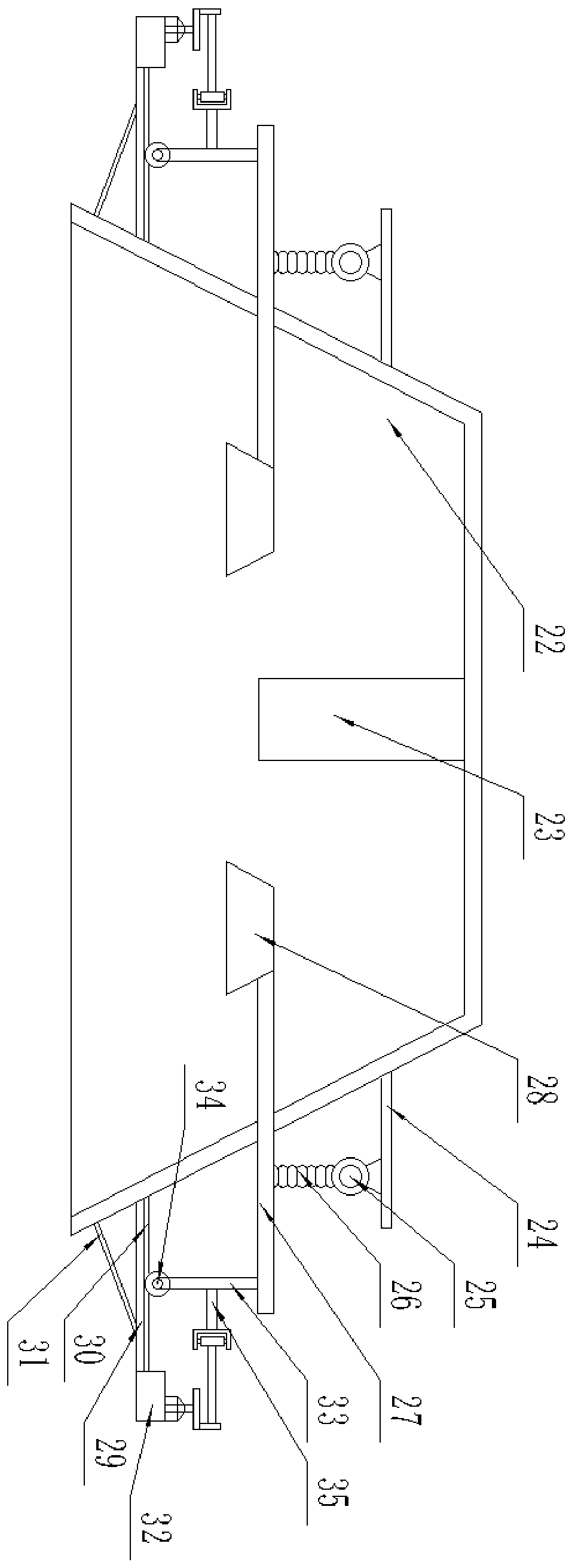

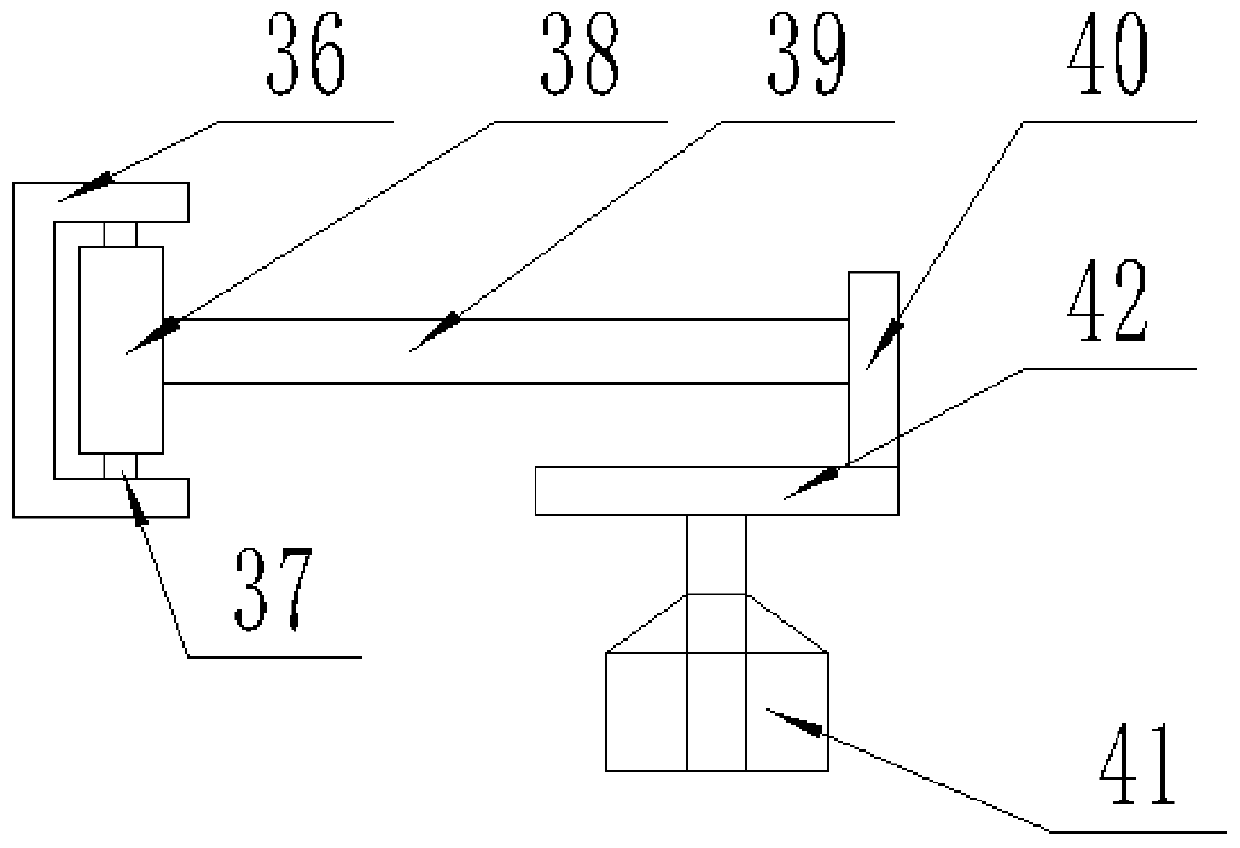

[0016] like Figure 1 to Figure 3 As shown, this specific embodiment adopts the following technical solutions: a scrap iron chip cleaning equipment for mechanical processing plants, including a base 1, an opening 2, an outer tube 3, a screw 4, a contact plate 5, a pulley rod 6, and a pulley 7 , housing 8, conveyor belt 9, first motor 10, first belt 11, beam 12, pole 13, first slide rail 14, slider 15, limit block 16, rack 17, gear rod 18, gear 19 , second motor 20, second belt 21, cleaning cover 22, electromagnet 23, upper rod 24, blower 25, hose 26, air duct 27, wind cover 28, lower rod 29, second slide rail 30, reinforcement 31. Motor mounting block 32, roller rod 33, roller 34, first connecting rod 35, concave frame 36, pin shaft 37, bushing 38, second connecting rod 39, hinged rod 40, third motor 41 and turntable 42 ; The lower surface of the base 1 is fixedly connected with an outer tube 3 and a pulley rod 6 around, a screw 4 is threaded in the outer tube 3, and a contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com