An automatic feeding and testing device for pcb boards

A detection device and PCB board technology, applied in transportation and packaging, electronic circuit testing, mechanical conveyors, etc., can solve problems affecting product quality, affecting production automation process, low efficiency of integrated circuit board material and detection, etc., to reduce The effects of manual operation, improvement of detection speed and efficiency, and improvement of feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

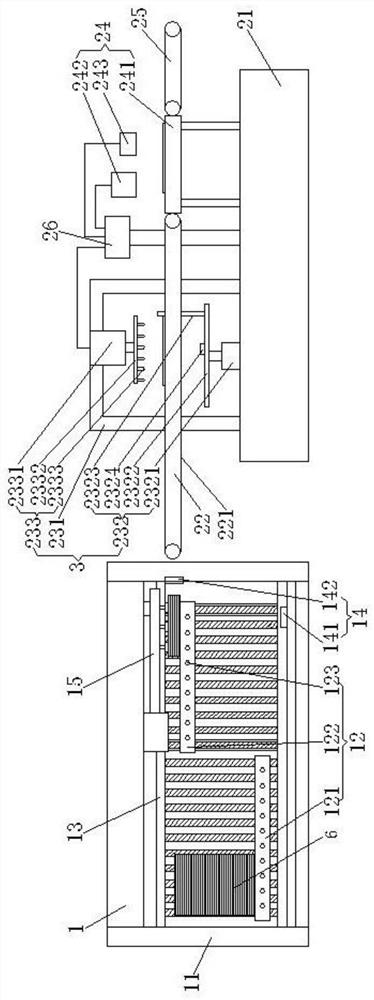

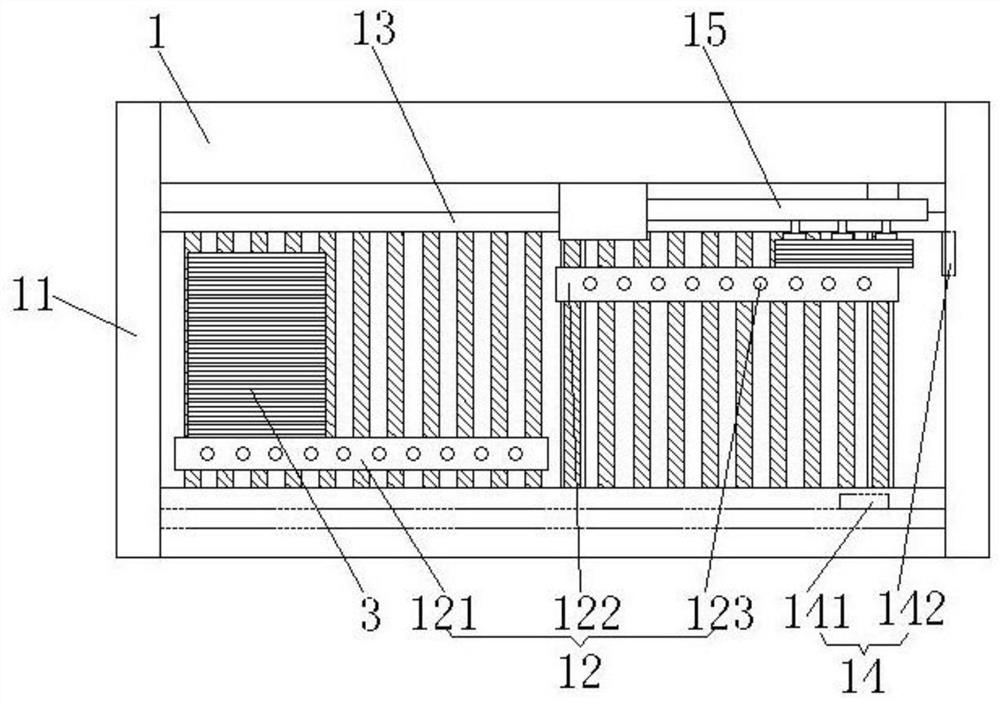

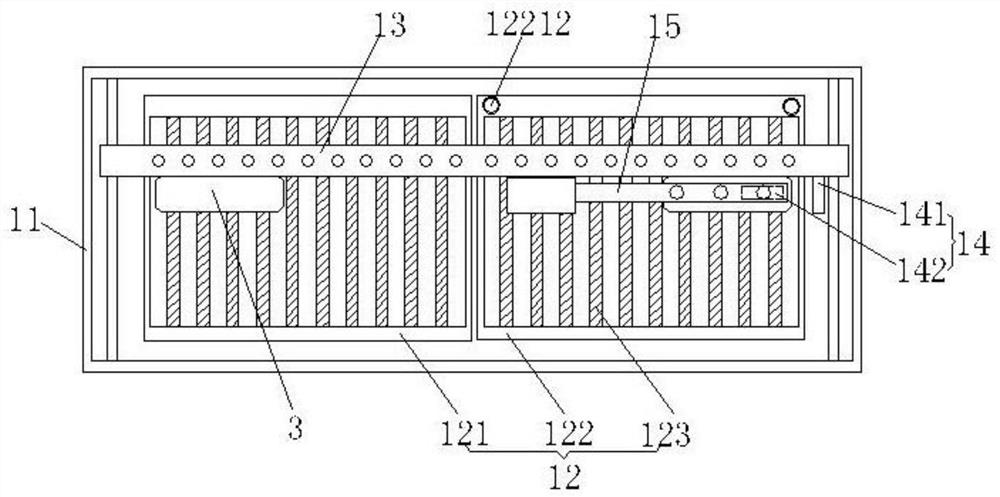

[0037] refer to Figure 1 to Figure 7 , this embodiment discloses an automatic loading and testing device for PCB boards, including a loading device 1 and a testing device 2, the loading device 1 is arranged before the testing device 2, and provides feeding services for the testing device 2.

[0038] The feeding device 1 includes a box body 11, a conveying platform 12, a movable limit device 13, an infrared sensing system 14, a mechanical sucker device 15 and an electrical control system (not shown in the figure), and the box body 11 is a cuboid hollow Box body, the box body 11 is provided with a conveying platform 12 , a movable limit device 13 and a mechanical sucker device 15 .

[0039] Described conveying platform 12 comprises fixed pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com