Design method of steel fiber self-compacting concrete mix ratio based on rheological properties of mortar

A technology of self-compacting concrete and steel fiber concrete, applied in the direction of ratio control, non-electric variable control, instruments, etc., can solve problems such as changes in concrete mechanical properties, achieve time reduction, high design accuracy, clear design steps and ideas Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0101] Taking the mix design of C50 steel fiber self-compacting concrete as an example, the water-binder ratio is determined to be 0.28, and the cementitious materials are ordinary Portland cement and fly ash, and the fly ash accounts for 30% of the cementitious material.

[0102] The mix ratio of mortar is designed as:

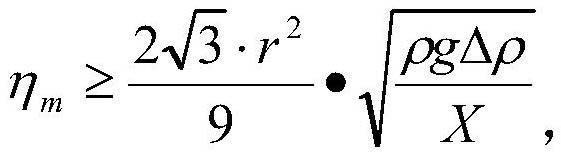

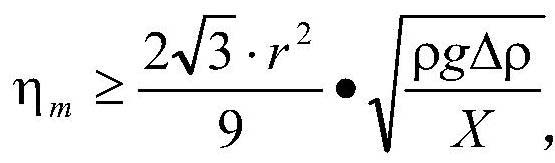

[0103] Plastic viscosity lower limit calculates according to the minimum plastic viscosity requirement of the mortar described in claim 3 (.

[0104] Table 1 Mortar mix ratio design and rheological parameters

[0105]

[0106] The base concrete mix ratio is:

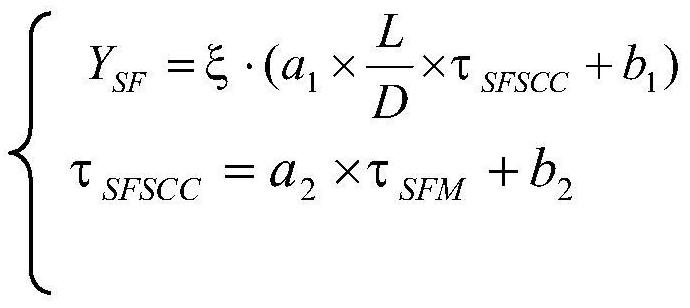

[0107] The predicted expansion degree is calculated according to the self-compacting concrete mix ratio design method based on the rheological properties of mortar.

[0108]

[0109] Table 2. Matrix concrete mix design

[0110]

[0111] The degree of expansion meets the requirements of self-compacting concrete. Morphological parameters of steel fibers:

[0112] Table 3. Steel fiber paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com