Preparation method of soybean protein peptide

A technology for soybean protein peptide and soybean protein isolate, which is applied in the field of preparation of soybean protein peptide, can solve the problems of low antioxidant property of soybean protein peptide, reduced effect of soybean protein peptide, and short storage time, etc., and achieves increased antioxidant capacity. effect, prolonging the storage time, and the effect of inactivating the enzyme is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

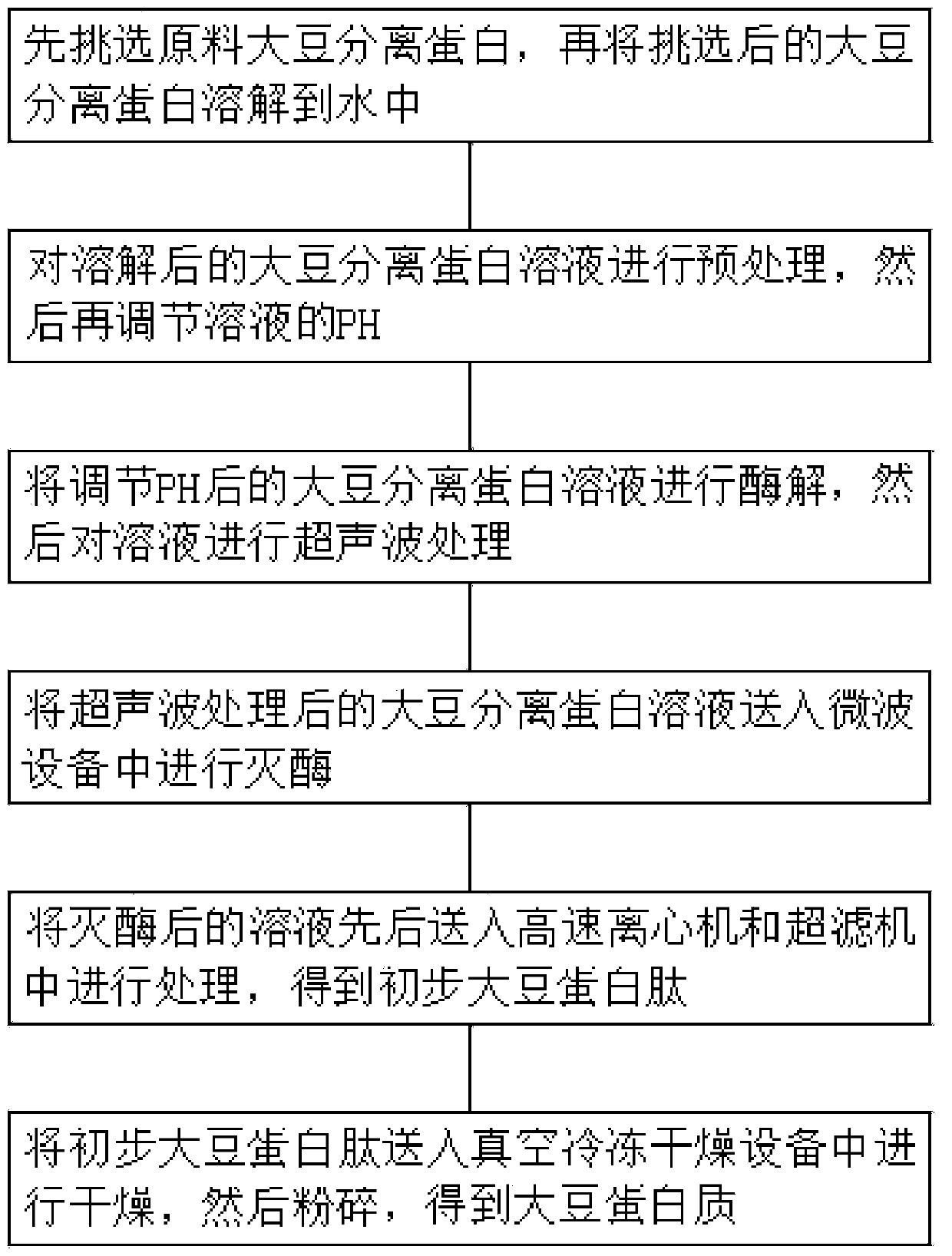

Method used

Image

Examples

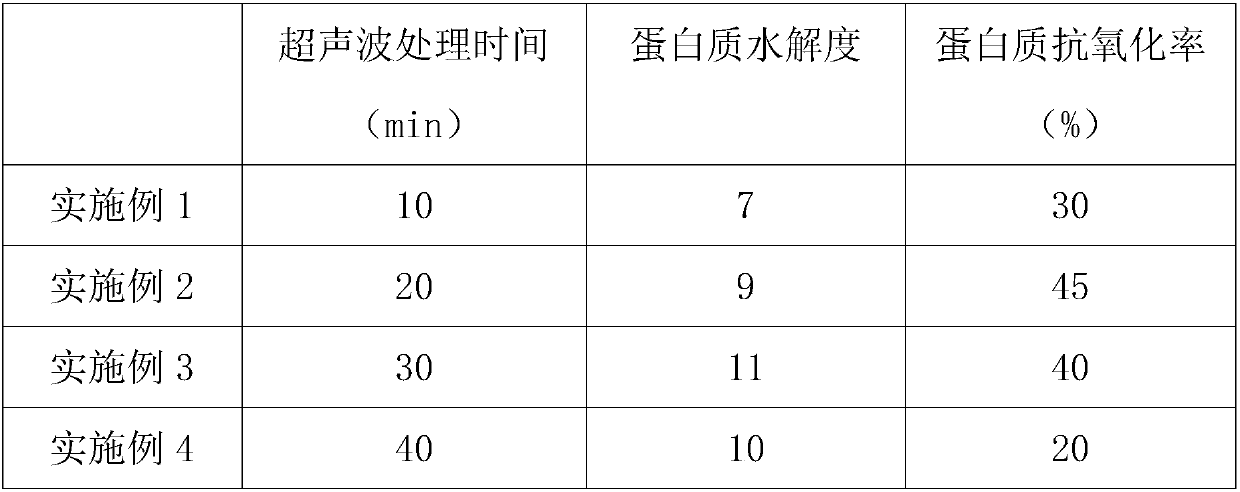

Embodiment 1

[0030] (1), first select the raw material powdery soybean protein isolate, and then send the selected powdery soybean protein isolate into water for dissolution. When dissolving, the powdery soybean protein isolate accounts for 10% of the whole. When dissolving, the water adopts deionized water, and soybean The protein isolate needs to be stirred with a high-speed mixer during the dissolution period. The speed of the high-speed mixer is 2500r / min, and the stirring time is 12 minutes;

[0031] (2), the soy protein isolate solution after dissolving is pretreated, and then the pH of the soy protein isolate solution is adjusted, and the concrete steps of pretreatment are as follows:

[0032] a. First heat the homogeneously dissolved soy protein isolate solution, stir continuously during the heating process, control the solution temperature at 75°C, and maintain the constant temperature for 5 minutes;

[0033] b. Send the PH-adjusted solution into a high-pressure homogenizer for hi...

Embodiment 2

[0040] (1), first select the raw material powdery soybean protein isolate, and then send the selected powdery soybean protein isolate into water for dissolution. When dissolving, the powdery soybean protein isolate accounts for 10% of the whole. When dissolving, the water adopts deionized water, and soybean The protein isolate needs to be stirred with a high-speed mixer during the dissolution period. The speed of the high-speed mixer is 2500r / min, and the stirring time is 12 minutes;

[0041] (2), the soy protein isolate solution after dissolving is pretreated, and then the pH of the soy protein isolate solution is adjusted, and the concrete steps of pretreatment are as follows:

[0042] a. First heat the homogeneously dissolved soy protein isolate solution, stir continuously during the heating process, control the solution temperature at 75°C, and maintain the constant temperature for 5 minutes;

[0043] b. Send the PH-adjusted solution into a high-pressure homogenizer for hi...

Embodiment 3

[0050] (1), first select the raw material powdery soybean protein isolate, and then send the selected powdery soybean protein isolate into water for dissolution. When dissolving, the powdery soybean protein isolate accounts for 10% of the whole. When dissolving, the water adopts deionized water, and soybean The protein isolate needs to be stirred with a high-speed mixer during the dissolution period. The speed of the high-speed mixer is 2500r / min, and the stirring time is 12 minutes;

[0051] (2), the soy protein isolate solution after dissolving is pretreated, and then the pH of the soy protein isolate solution is adjusted, and the concrete steps of pretreatment are as follows:

[0052] a. First heat the homogeneously dissolved soy protein isolate solution, stir continuously during the heating process, control the solution temperature at 75°C, and maintain the constant temperature for 5 minutes;

[0053] b. Send the PH-adjusted solution into a high-pressure homogenizer for hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com