Multi-stage buffering energy-consumption type anti-bumping corrosion-resistance steel floating box

A corrosion-resistant steel and energy-consuming technology, applied in the field of multi-level buffer energy-consuming anti-collision corrosion-resistant steel pontoons, can solve the problems of unclear performance classification, single anti-collision defense line, etc. The effect of outstanding energy consumption ability and strong self-floating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

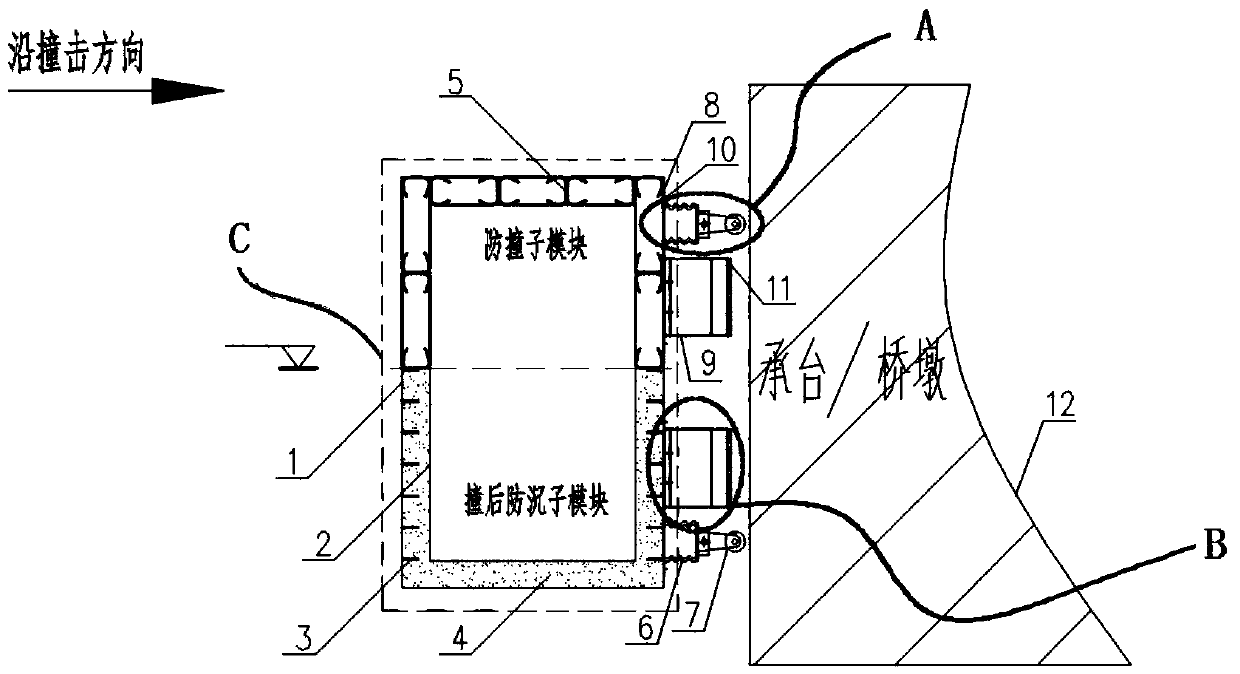

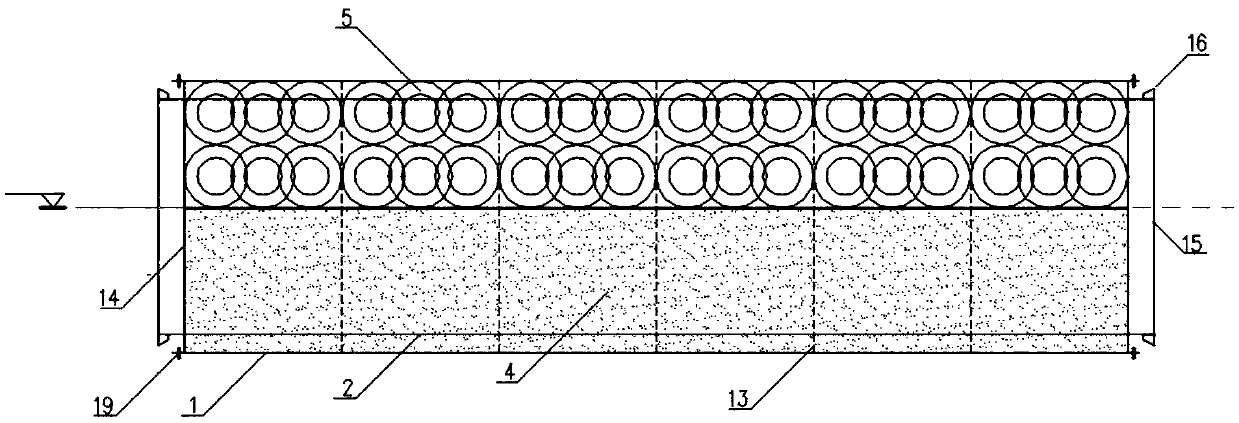

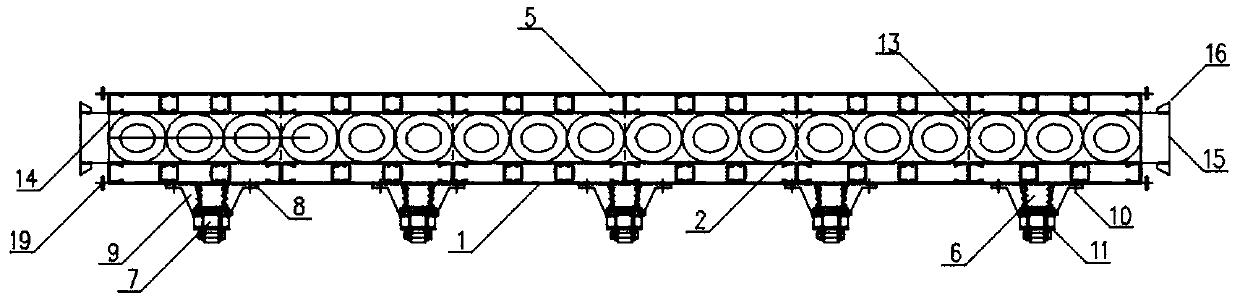

[0067] A kind of anti-collision and anti-corrosion steel pontoon of multi-stage buffer energy consumption type, its structure sees Figure 1 to Figure 14 As shown, it includes several anti-collision sections arranged around the pier or cap, and each anti-collision section includes:

[0068] The first level of cushioning - indentable rolling contact module A: includes a backing plate 8 sequentially stacked along the impact direction, a cylindrical folded belly energy-absorbing base 6, and a rolling assembly (metal roller) 7, wherein the cylindrical folded The abdominal energy-absorbing base 6 and the backing plate 8 are connected by welding, the backing plate 8 and the outer steel box 1 are provided with bolt holes 19 , and the backing plate 8 is connected with the outer steel box 1 through high-strength bolts 10 .

[0069] Second-stage energy absorption-sliding contact module B: including SA-type rubber fenders 9 stacked in sequence along the impact direction, the top surface ...

Embodiment 2

[0087] A kind of anti-collision and anti-corrosion steel pontoon of multi-stage buffer energy consumption type, its structure sees Figure 23 As shown, the difference from Embodiment 1 is that the rubber-like material (rubber tire) 5 passes through the uppermost welded longitudinal stiffening rib 3 on the outer steel box 1, and the vertical device is put into the outer steel box 1 and the inner steel box vertically in the axial direction. Space is reserved on both sides of the box 2, and longitudinal stiffening ribs 3 are arranged on the outer steel box 1 and the inner steel box 2.

[0088] The difference from Embodiment 1 is that the first-stage buffering-retractable rolling contact module is a square tube-shaped belly-folding energy-absorbing base 22. The structural diagram is shown in Figure 24 . A D-shaped rubber fender 21 is arranged in the second-stage energy-absorbing-sliding contact module.

[0089] As shown, the example crash-resistant steel box fits well into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com