A clean and environment-friendly reverse circulation piling system for construction platforms of high trestle bridges

A construction platform, clean and environmentally friendly technology, applied in sheet pile walls, infrastructure engineering, wellbore/well components, etc., can solve the serious environmental problems of high trestle bridges, save construction platform space, improve construction efficiency, and work efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

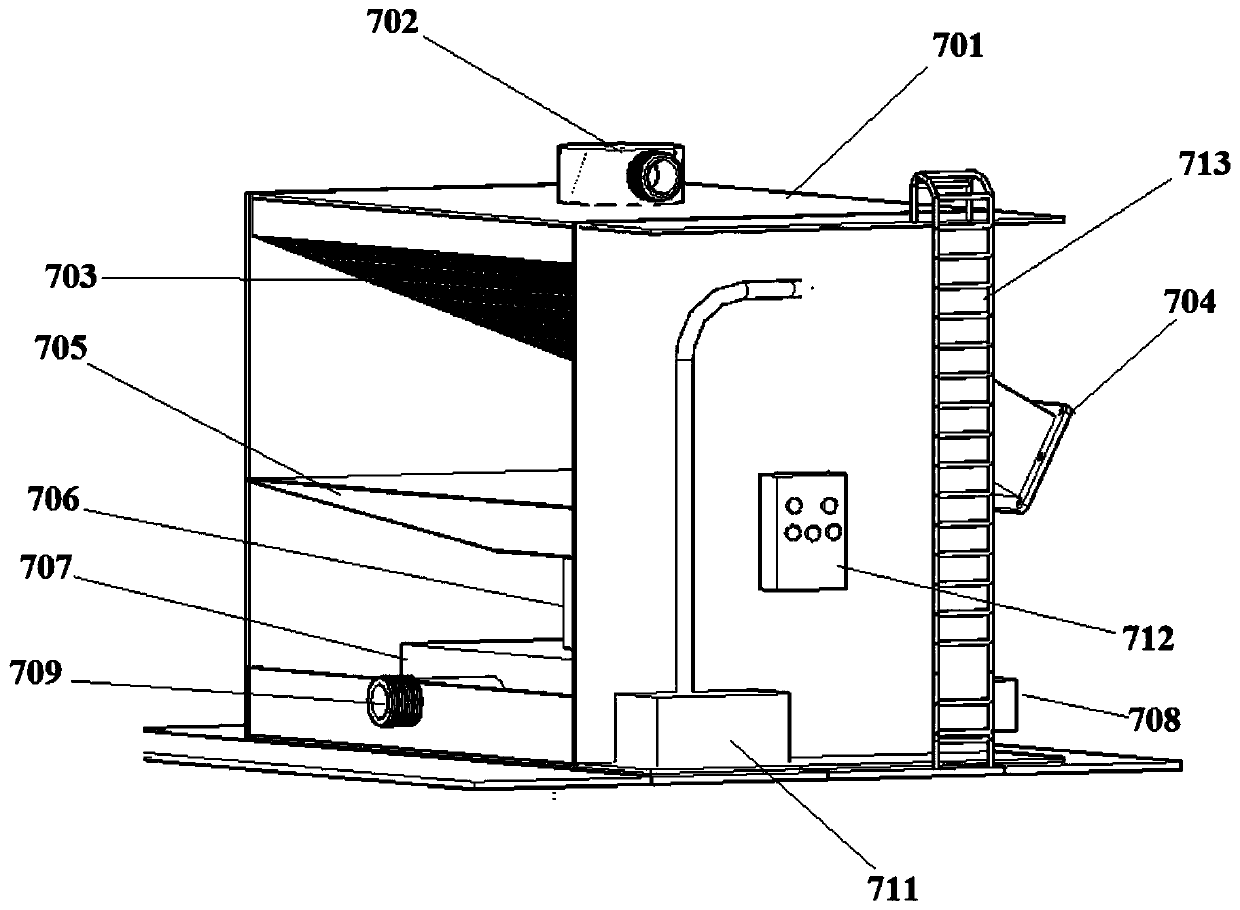

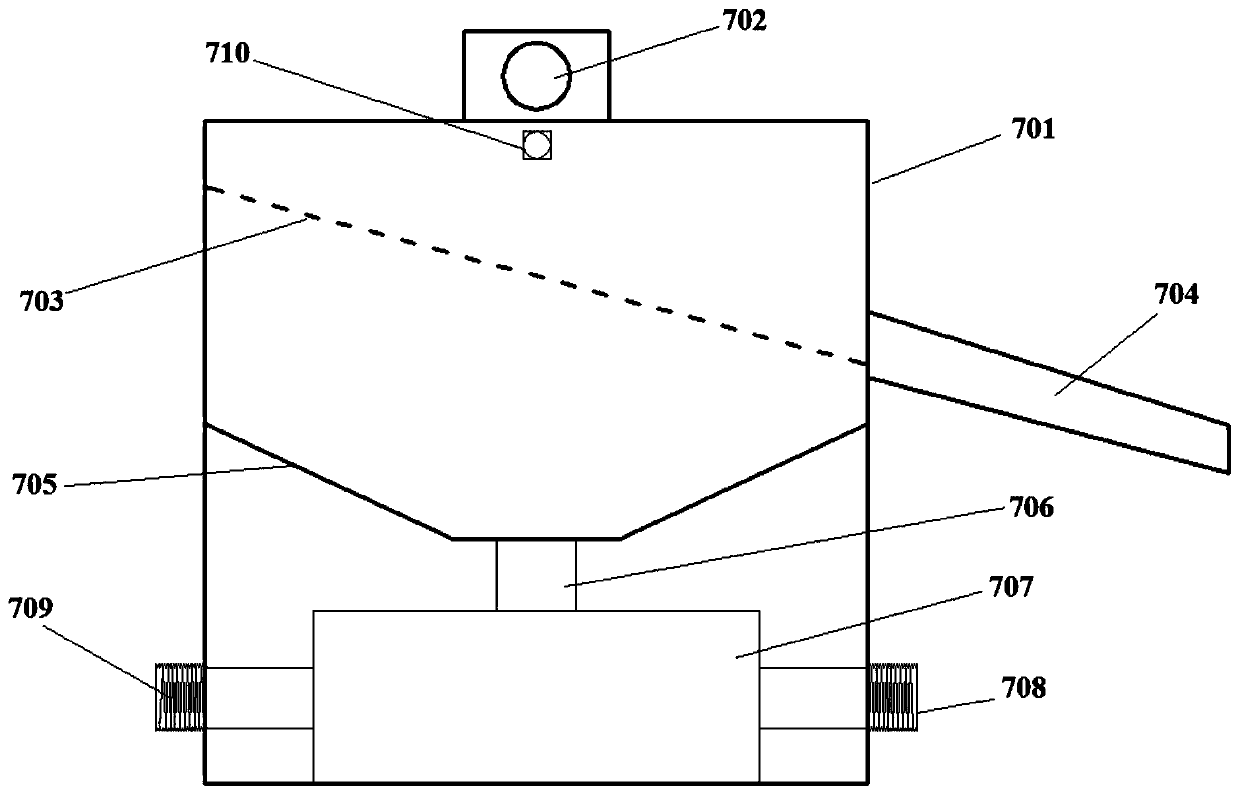

[0043] Following the above technical solutions, this embodiment provides a drilling slag sedimentation filter box for the reverse circulation pile formation system of the high trestle construction platform, such as Figure 2 to Figure 4 As shown, it includes a closed box body 701, the top of the box body 701 is provided with a slag inlet 702, the box body 701 is provided with a vibrating filter screen 703, and the side wall of the box body 701 on the side of the vibrating filter screen 703 is provided with slag discharge In the tank 704, the box 701 under the vibrating filter screen 703 is provided with a mud diversion bucket 705. The mud diversion bucket 705 is connected to a mud separator 707 through a connecting hose 706. The mud separator 707 is installed at the bottom of the box 701. One end of the separator 707 communicates with the sludge discharge port 708 on the side wall of the box body 701, and the other end of the slurry separator 707 communicates with the slurry outl...

Embodiment 2

[0050] Following the above technical solution, this embodiment provides a drilling slag storage box for the reverse circulation pile formation system of a high trestle construction platform, such as Figure 5 with Image 6 As shown, it includes a drill slag storage tank 802 and a sludge storage tank 803 separated by a partition 801, and the drill slag storage tank 802 is located above the sludge storage tank 803;

[0051] A slag inlet pipe 804 is provided on one side of the drilling slag storage box 802 near the top, and a slag outlet 805 is provided on the other side of the drilling slag storage box 802 near the bottom;

[0052] The drilling slag storage box 802 is provided with a rotating bottom plate 806 close to the partition 801. One end of the rotating bottom plate 806 is rotatably installed at the end of the partition 801 near the slag outlet 805. The other end of the rotating bottom plate 806 is connected to the drilling slag storage box. The arc-shaped inner wall 807 of the...

Embodiment 3

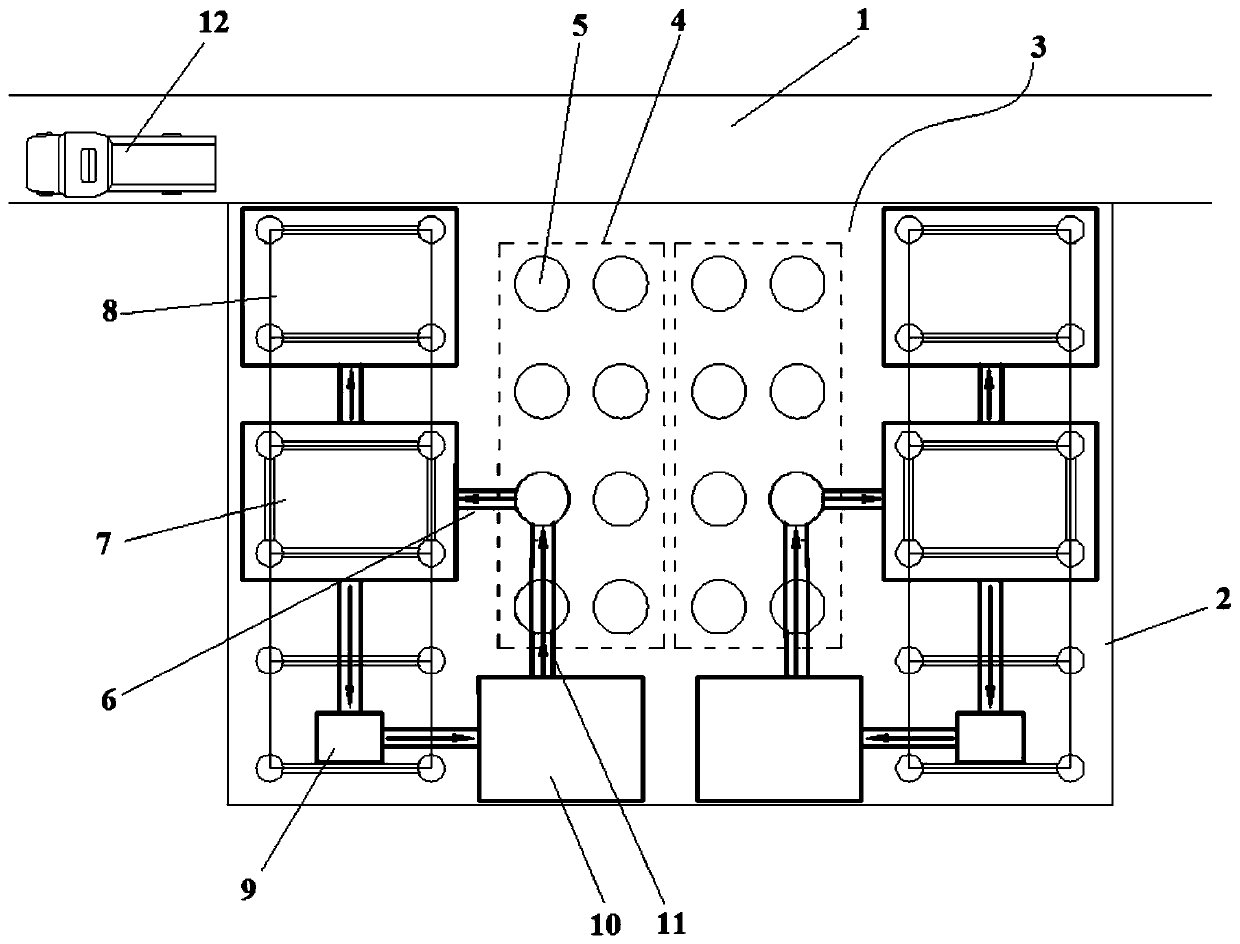

[0062] Following the above technical solution, this embodiment provides a clean and environmentally friendly high-trestle bridge construction platform reverse circulation piling system, such as Figure 1 to Figure 6 As shown, it includes a main trestle bridge 1 and a branch trestle bridge 2 arranged on one side of the main trestle bridge 1. A plurality of reverse circulation pile forming units 3 are arranged on the branch trestle bridge 2;

[0063] Each reverse circulation pile-forming unit 3 includes a steel protective tube group 4, and the steel protective tube group 4 includes a plurality of steel protective tubes 5; the steel protective tube 5 passes through the first connecting pipe 6 and the slag inlet filter box 7 The port 702 is connected, the slag tap 704 on the side of the drill slag sedimentation filter box 7 is connected with the slag inlet pipe 804 of the closed slag storage tank 8, and the sludge discharge port 708 on the side of the drill slag sedimentation filter b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com