Landfill lining layer anchoring structure using rice hull ash concrete

An anchoring structure and concrete technology, which is applied in the direction of basic structure engineering, solid waste removal, protection devices, etc., can solve the problems of difficult maintenance and reinforcement, long construction period, and large engineering volume, so as to achieve a scientific and reasonable overall layout of the landfill, shorten The effect of improving the construction period and working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

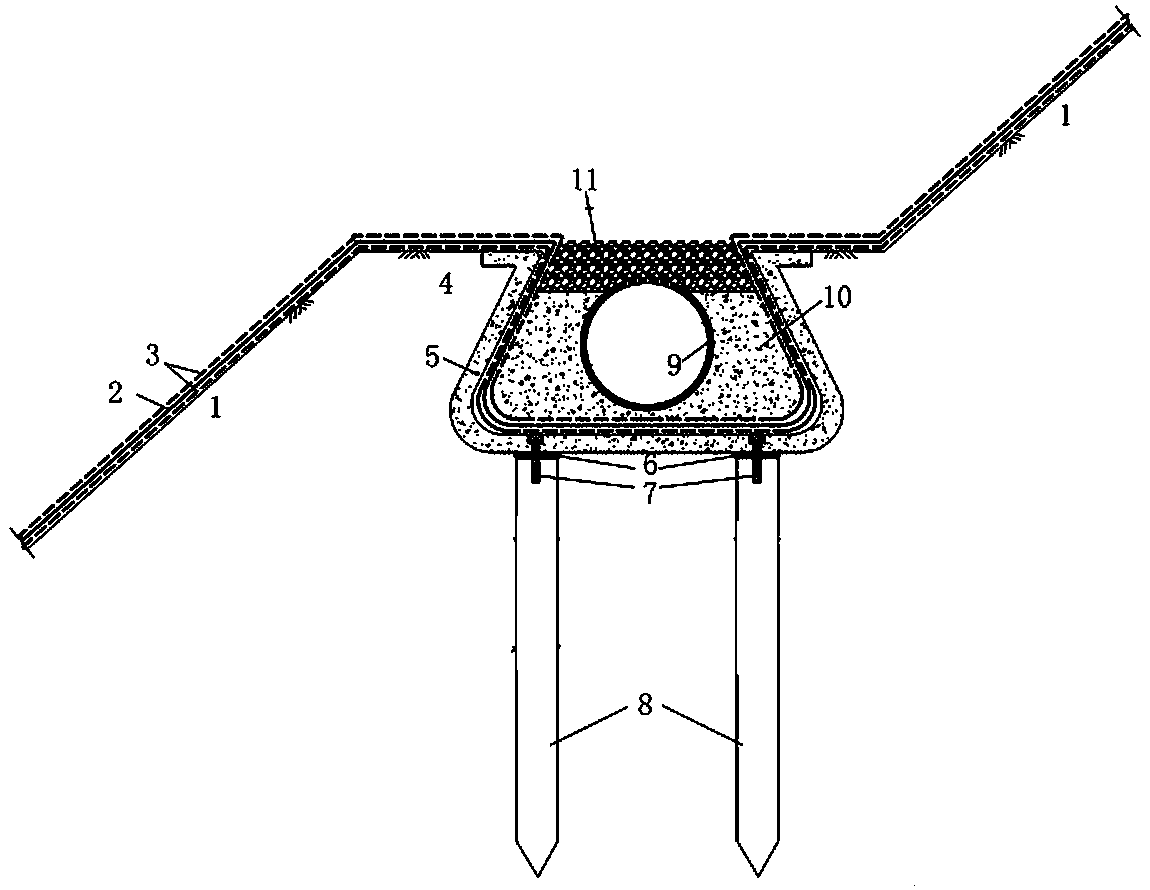

[0025] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 As shown, trenches are excavated at the top of the slope or at the middle platform, and prefabricated concrete anchor piles are driven into the bottom of the trenches, and then the rice husk ash concrete anchor shells are fixed to the concrete anchor piles through expansion bolts and rubber gaskets. upper end. Backfill the grooves on both sides of the anchorage shell to the level of the top surface. Fold the lower geotextile, anti-seepage geomembrane and upper geotextile of the liner material in the anchor shell of rice husk ash concrete in turn, then place the upper perforated PVC pipe in the lower part of the anchor shell, and pour rice husk ash concrete around it to fill After the health preservation is qualified, the upper part is filled with gravel.

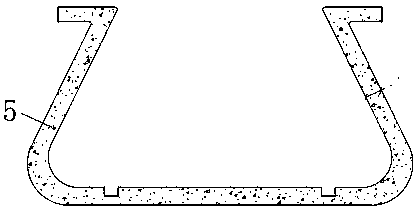

[0026] Such as figure 2 As shown, the anchor shell is made of rice husk ash concrete material, which has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com