Cracking and permeability increasing device capable of pressurizing liquid nitrogen to dissolve coal body and permeability increasing experiment method

A technology of liquid nitrogen and coal body, applied in the direction of mining fluid, earth square drilling, measurement, etc., can solve the problems affecting the extraction efficiency, shortage, low permeability of coal seam, etc., and achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

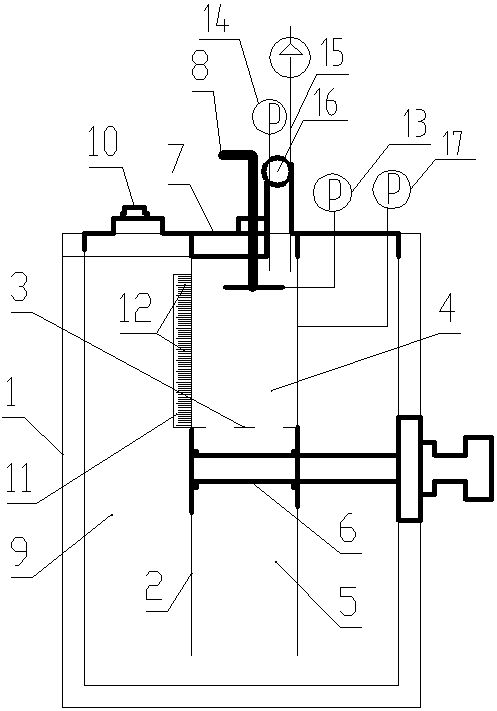

[0033] Such as figure 1 As shown, the experimental pressurized liquid nitrogen leaching gas-containing coal fracturing anti-reflection device of the present invention includes a hollow cylindrical insulation cylinder 1, the insulation cylinder 1 is vertically arranged, and both axial ends of the insulation cylinder 1 are closed The center of the top wall of the insulation cylinder 1 is connected downward with a hollow cylindrical inner cylinder 2, and there is a gap between the bottom end of the inner cylinder 2 and the bottom wall of the insulation cylinder 1; a pressure-resistant metal mesh 3 is installed horizontally in the middle of the inner cylinder 2, The pressure-resistant metal mesh 3 separates the inner cylinder 2 into a coal chamber 4 and a liquid inlet chamber 5;

[0034] An isolation valve 6 is installed in the middle of the inner cylinder 2. The isolation valve 6 is located below the pressure-resistant metal mesh 3 and adjacent to the pressure-resistant metal mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com