Quantitative detection method for microcosmic combination of single ceramic spread sheet and matrix

A quantitative detection method and combined technology, which is applied in the field of quantitative detection of the microcosmic bonding between a single ceramic spreader and the substrate, and can solve the problem of not fully showing the overall situation of the bonding interface between the bottom surface of a single spreader and the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

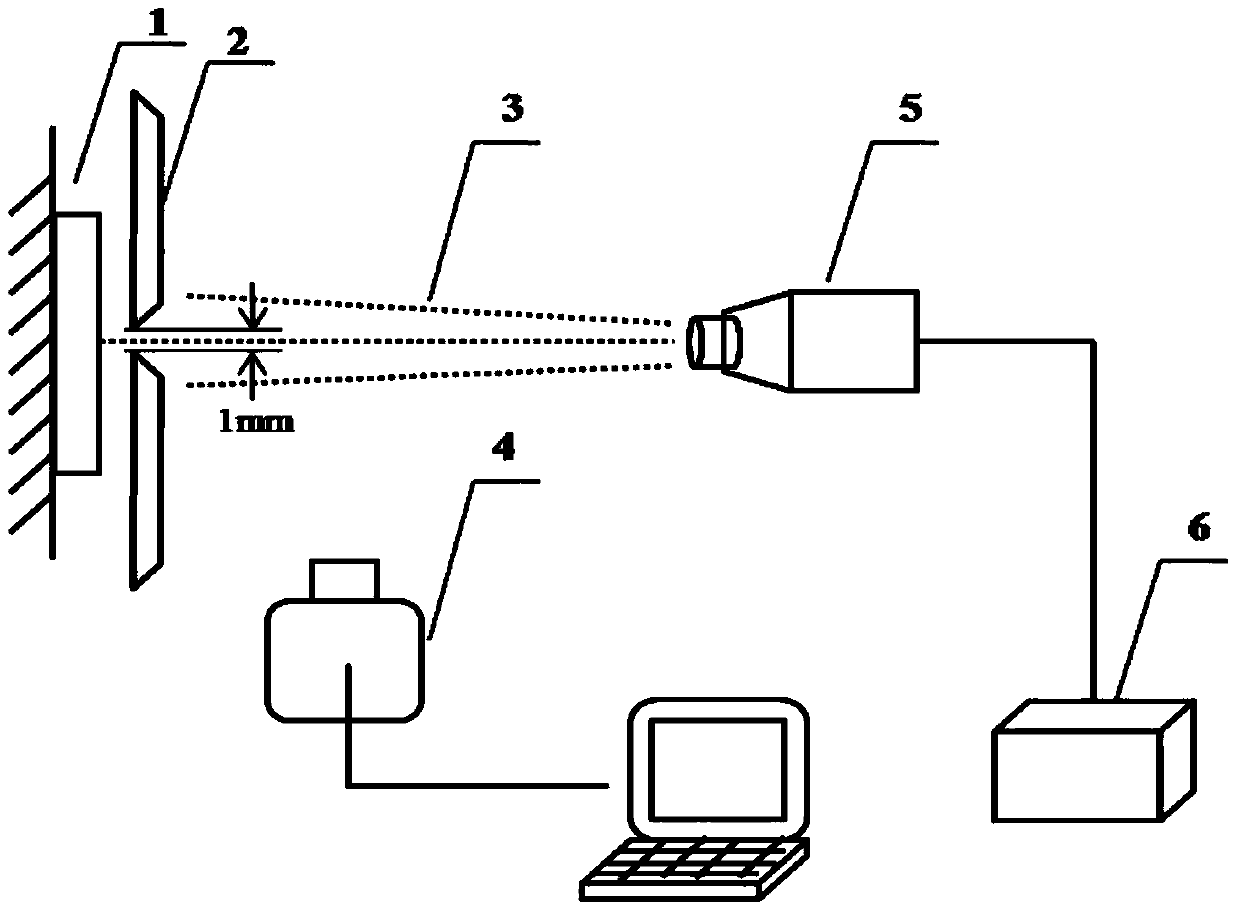

[0041] Based on the above method, adjust the following parameters of the spray gun 5: power 48kV, current 650A, voltage 74V, main gas 47slpm and secondary gas 11.8slpm, and adjust the spraying distance between the spray gun 5 and the substrate 1 to 80mm, and through the controllable device 6 Adjust the powder feeding rate to 38g·min -1 , to test the flight properties and microcosmic bonding of ceramic droplets. During the test, the temperature measurement and speed measurement system 4 was used to monitor the surface temperature of the molten droplets online at 2901±5K, and the flight speed was 238±3m·s -1 .

[0042] The final measured micro-shear strength is 7.8±0.1MPa.

[0043] Embodiment 2-embodiment 7 see table 2 for details.

[0044] Based on the embodiment 1-7 of table 1, establish as Figure 5 The quantitative relationship between the flying properties of the ceramic droplet and the microcosmic bonding rate and bonding strength between the spreader and the matrix is ...

specific Embodiment

[0045] The flight properties and microcosmic bonding of ceramic droplets under the specific examples of table 1

[0046]

[0047] As can be seen from Table 1, the embodiment illustrates the microcosmic combination between the spread and the matrix formed by the molten droplets under different flight properties in the plasma jet and their impact on the substrate, indicating that with the increase of the temperature speed, the microcosmic combination rate and Bond strength is also improved.

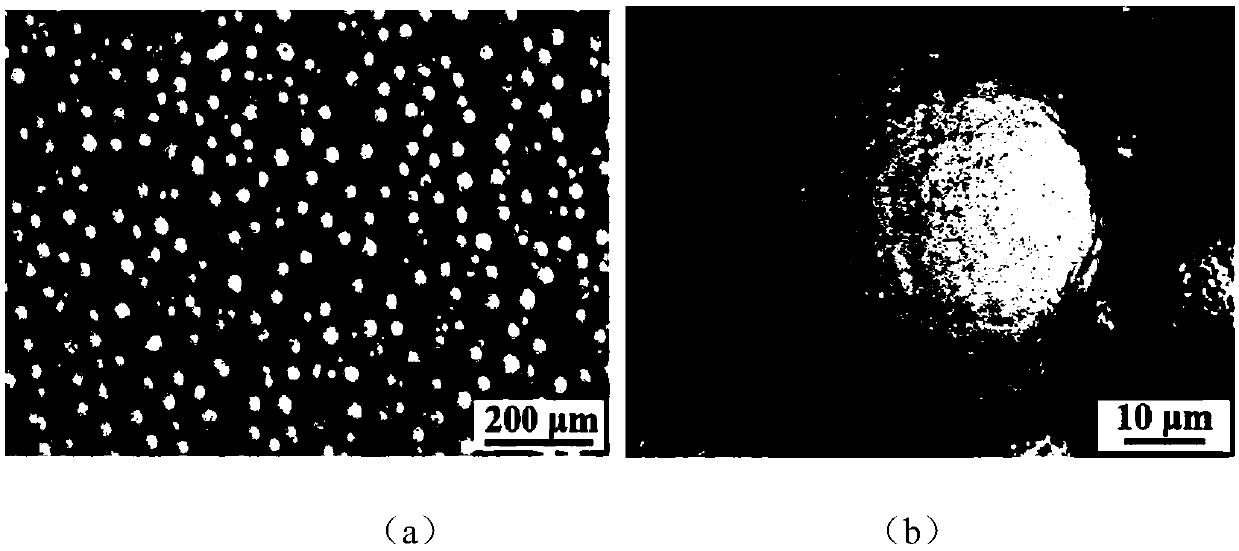

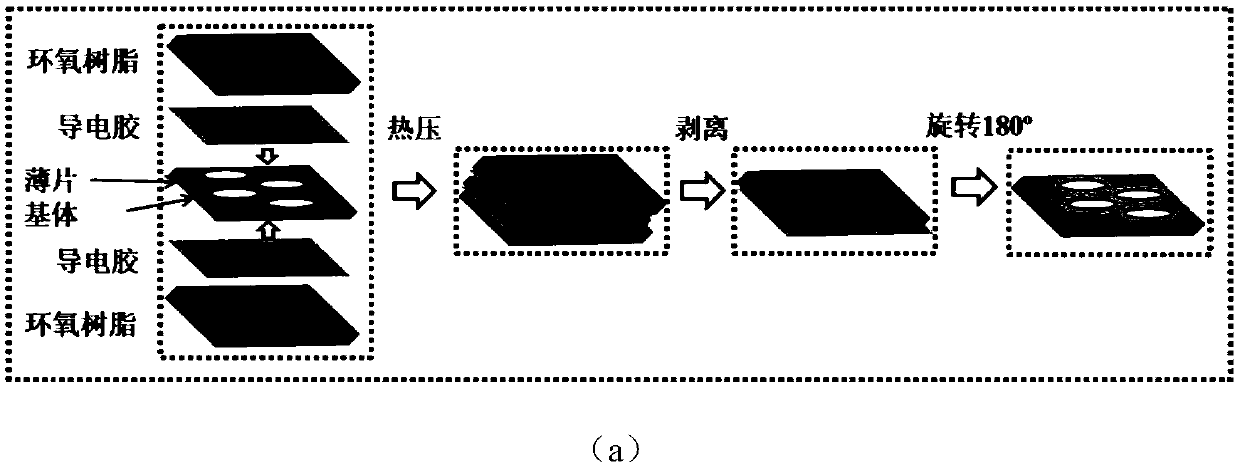

[0048] The present invention provides a method for quantitatively detecting the combination of the spread and the substrate formed by the impact of ceramic droplets on the substrate in the plasma jet. Ceramic droplets under different flight properties can be obtained by on-line monitoring of the temperature and speed of the molten droplets in different embodiments. At the same time, the pressure bonding method is used to quantitatively detect the microscopic bonding area between the bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com